Composite lining structure of shield water delivery tunnel, and construction method for same

A technology of water conveyance tunnel and composite lining, applied in tunnel lining, wellbore lining, drainage, etc., can solve the problems of increased maintenance cost, unreasonable load sharing ratio, single structure of drainage system, etc., to improve durability and service life, Improve the stability of external pressure resistance and ensure the effect of pipeline water delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

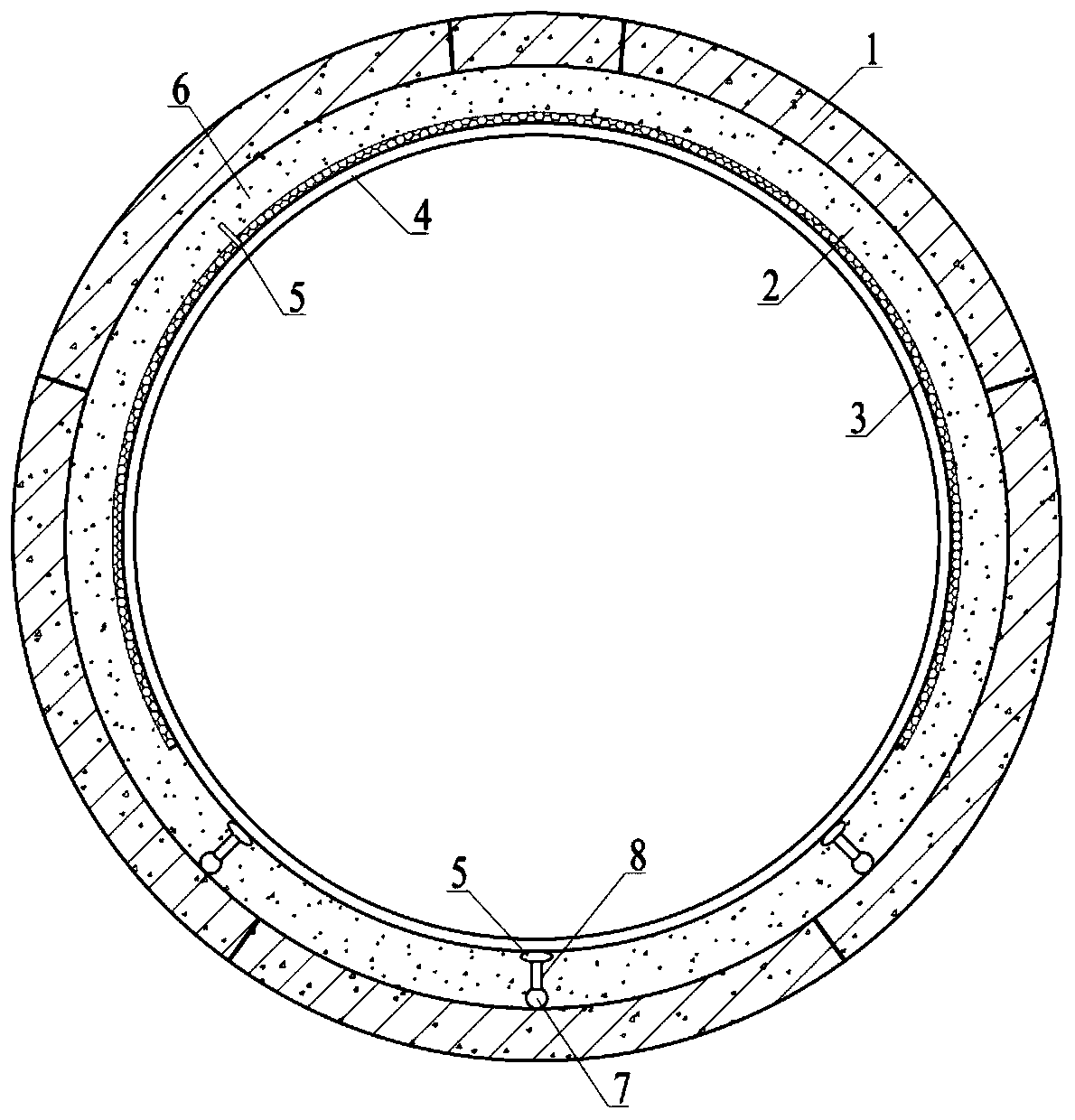

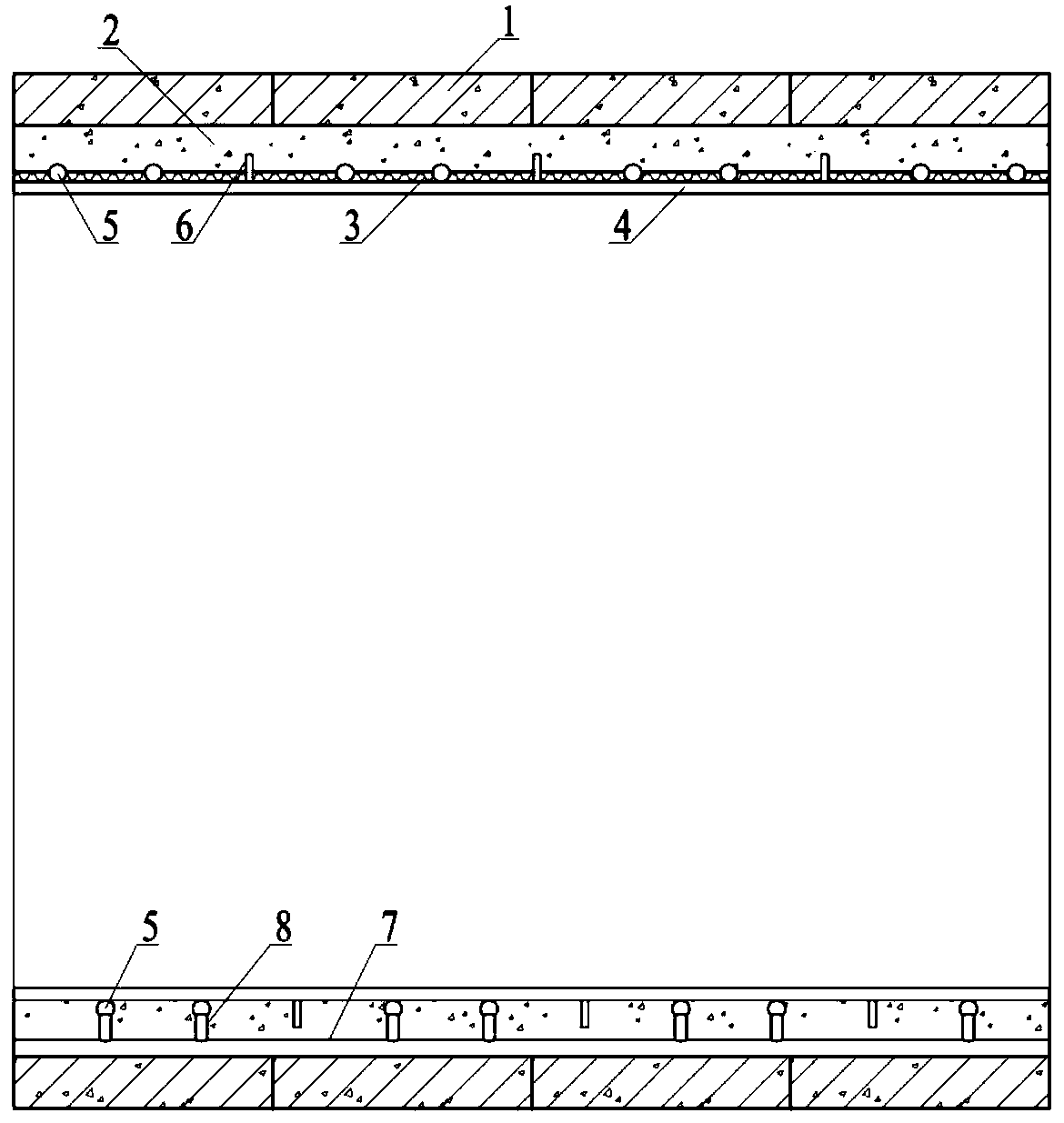

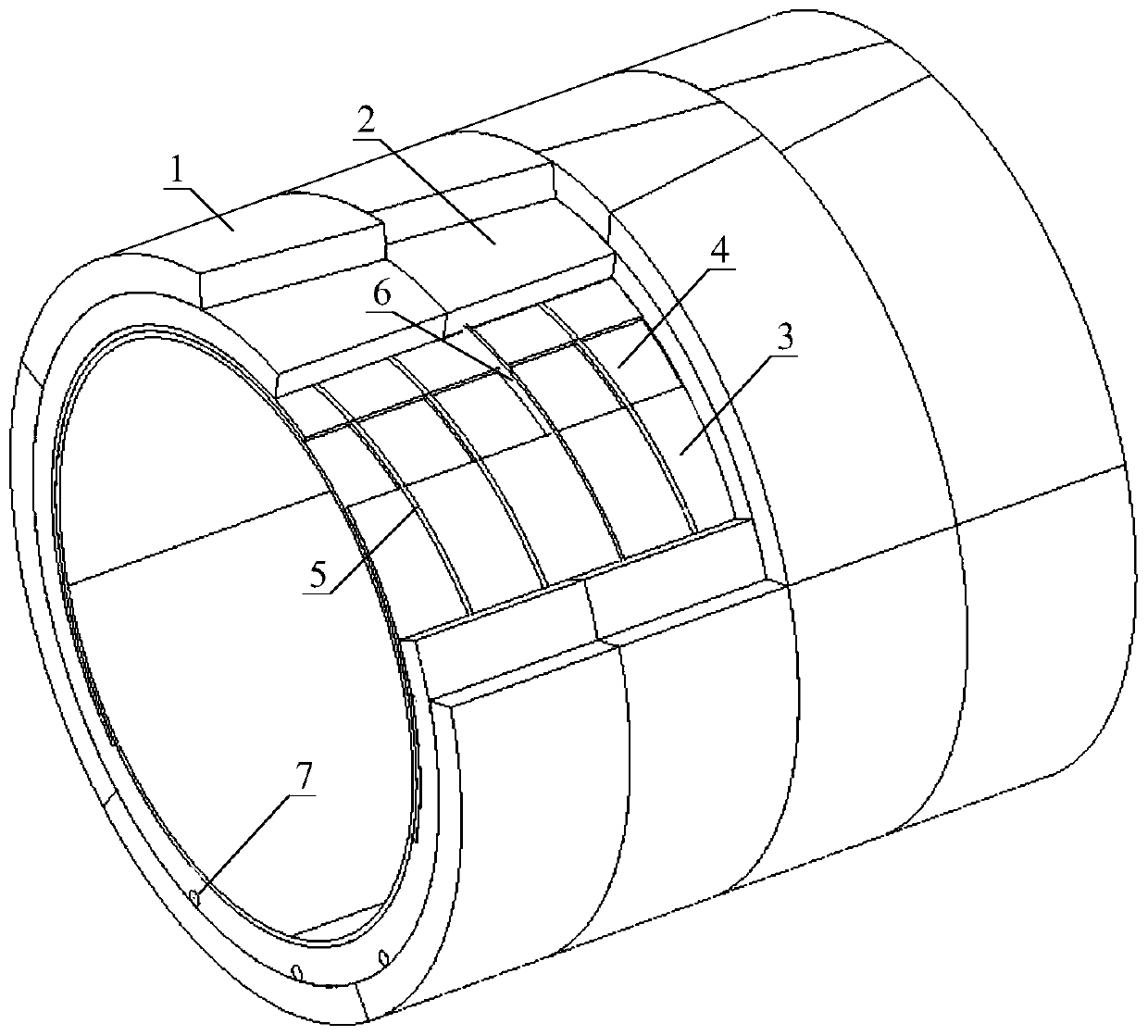

[0035] As shown in the accompanying drawings, a composite lining structure of a shield water conveyance tunnel includes an outermost shield tunnel segment 1, an inner steel lining 4, the steel lining 4 is cylindrical, and the steel lining 4 The outer surface of the steel lining 4 is welded with a stiffening ring 6, the outer surface of the steel lining 4 is provided with a flexible liner 3 at 240° to 300°, the outer surface of the steel lining is provided with a drainage flower tube 5, and the shield tunnel segment 1 is provided with a longitudinal drainage pipe 7 at the inner bottom, the drainage flower pipe 5 communicates with the longitudinal drainage pipe 7 through a connecting conduit 8, and concrete is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com