High-temperature-resistant polyurethane ink binder as well as preparation method and application thereof

An ink binder, polyurethane technology, applied in the field of ink printing, can solve the problems of poor printing of active particles, long unsealing time, reduced polyurethane solubility, etc., to achieve excellent printing adaptability, weaken interaction, and improve heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

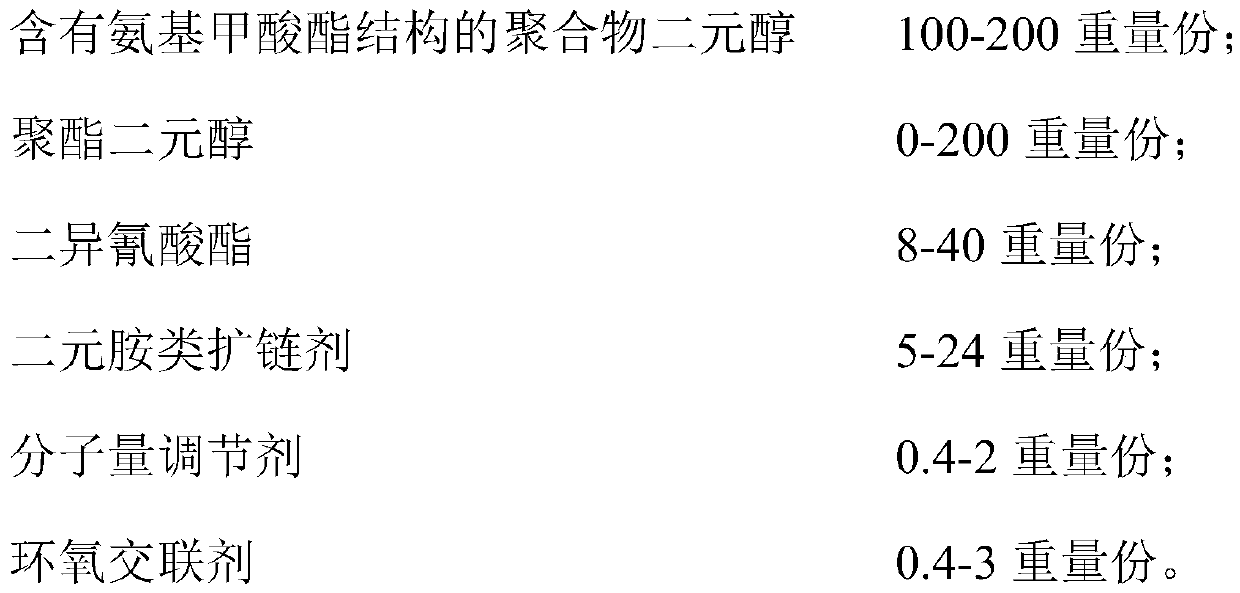

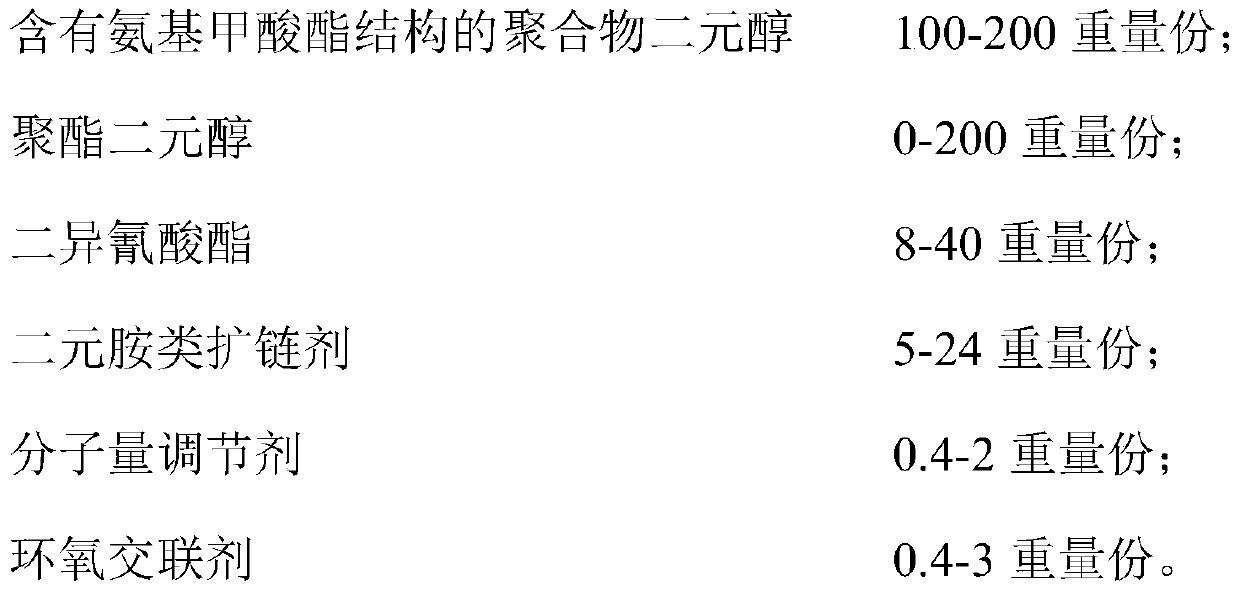

[0041] The high-temperature-resistant polyurethane ink binder described in this embodiment includes the following composition in terms of the total amount of raw materials for its preparation:

[0042] 29.5wt% of raw materials for preparing the polyurethane;

[0043] Ethyl acetate 42.1wt%;

[0044] Isopropanol 28.4 wt%.

[0045] The preparation method of high temperature resistant polyurethane ink binder described in the present embodiment comprises the following steps:

[0046] (1) Mix 100 g of the polymer diol containing a carbamate structure, 8 g of diisocyanate, and 15 g of ethyl acetate uniformly in container 1, heat up to 110° C. and react for 2 hours to obtain a prepolymer; and add 60g ethyl acetate, stir 20min, obtain prepolymer dilution;

[0047](2) Add 5g of diamine chain extender, 0.4g of molecular weight modifier, 60g of ethyl acetate and 60g of isopropanol into container 2 and mix evenly to obtain a mixed solution, which is kept at 40°C;

[0048] (3) Pass N 2...

Embodiment 2

[0052] The high-temperature-resistant polyurethane ink binder described in this embodiment includes the following composition in terms of the total amount of raw materials for its preparation:

[0053] 32.3wt% of raw materials for preparing the polyurethane;

[0054] Ethyl acetate 67.7wt%.

[0055] The preparation method of high temperature resistant polyurethane ink binder described in the present embodiment comprises the following steps:

[0056] (1) Mix 200g of polymer diol containing urethane structure, 200g of polyester diol (molecular weight: 4000), 40g of diisocyanate, and 60g of ethyl acetate in container 1, and heat up to 110°C for reaction 2h to obtain a prepolymer; and add 350g of ethyl acetate and stir for 40min to obtain a prepolymer dilution;

[0057] (2) Add 24g of diamine chain extender, 2g of molecular weight regulator, and 500g of ethyl acetate into container 2, mix well, and keep warm at 55°C;

[0058] (3) Pass N 2 Transfer the prepolymer dilution from c...

Embodiment 3

[0062] The high-temperature-resistant polyurethane ink binder described in this embodiment includes the following composition in terms of the total amount of raw materials for its preparation:

[0063] 30wt% of raw materials for preparing the polyurethane;

[0064] Ethyl acetate 50wt%;

[0065] Isopropanol 20wt%.

[0066] The preparation method of high temperature resistant polyurethane ink binder described in the present embodiment comprises the following steps:

[0067] (1) Mix 200g of polymer diol containing urethane structure, 200g of polyester diol (molecular weight 4000), 25g of diisocyanate, and 60g of ethyl acetate in container 1, and heat up to 90°C for 3 hours , to obtain a prepolymer; and add 200g ethyl acetate, stir for 40min, to obtain a prepolymer dilution;

[0068] (2) Add 12g of diamine chain extender, 0.8g of molecular weight modifier, 400g of ethyl acetate and 200g of isopropanol into container 2, mix evenly, and keep warm at 40°C;

[0069] (3) Pass N 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com