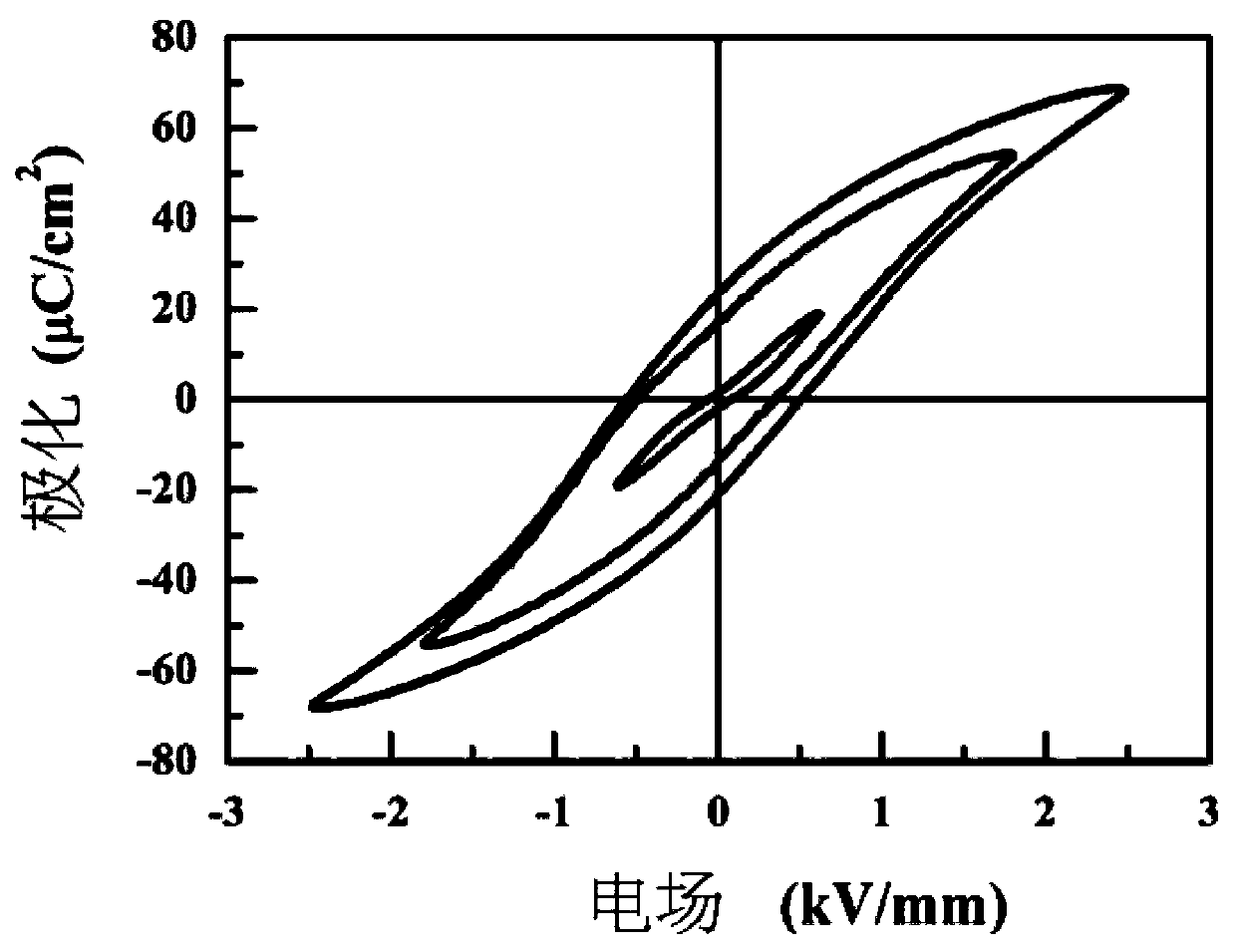

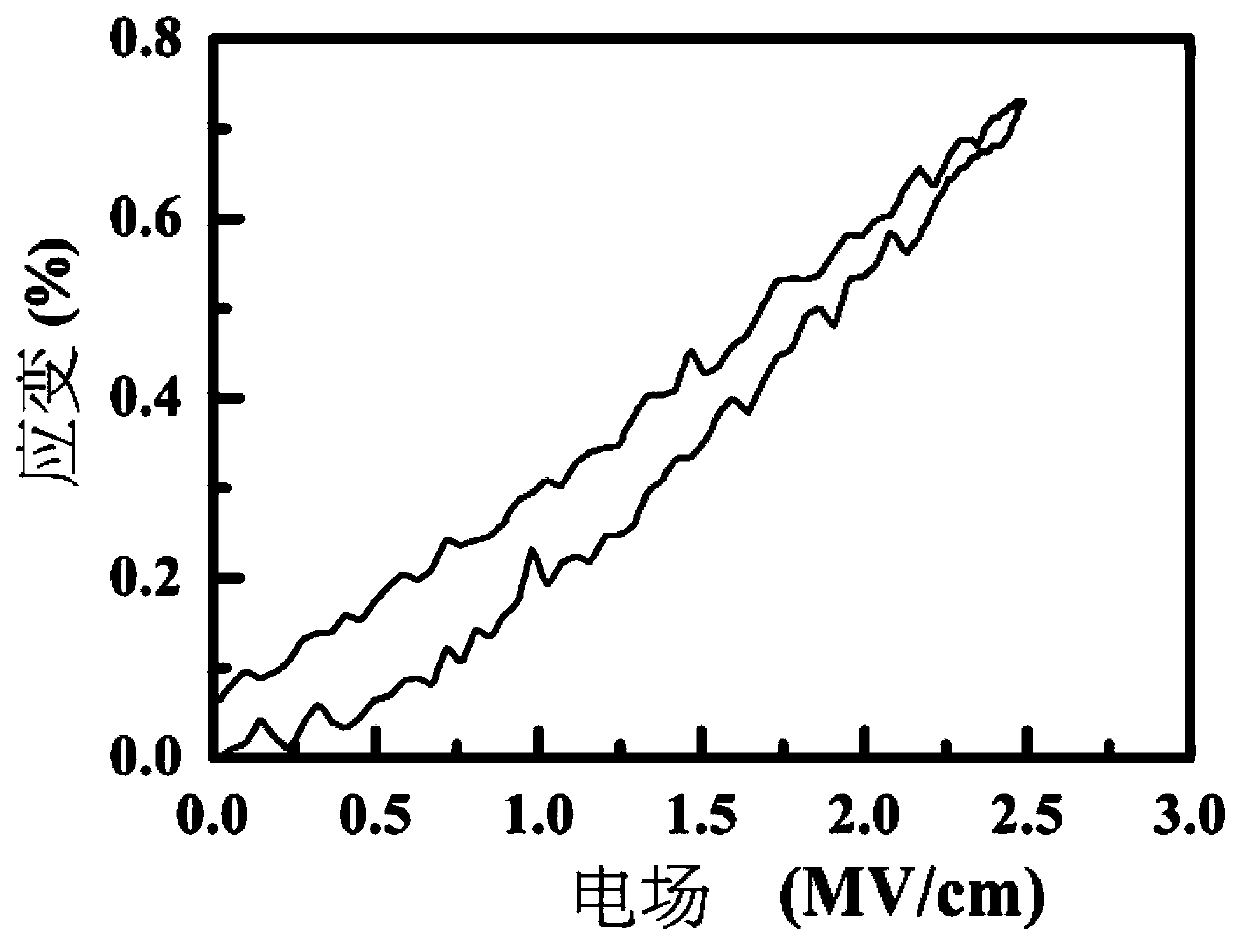

Bismuth ferrite based thin film having high polarization intensity and large strain characteristics and preparation method thereof

A polarization, bismuth ferrite-based technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of difficult preparation and poor film performance, and achieve good crystallinity, good compactness, and smoothness. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a bismuth ferrite thin film with high polarization strength and large strain performance, comprising the following steps:

[0042] (1) Target preparation

[0043] By Bi 2 o 3 、BaCO 3 、TiO 2 , MnCO 3 , Fe 2 o 3 Powder is used as raw material, and 0.7Bi is prepared according to the stoichiometric ratio of corresponding elements x FeO 3 -0.3BaTiO 3 +ywt%MnCO 3 Ceramic target, where x=1.1, y=0.1. The sintering temperature is 1100°C. The sintering time is 240min. The sintering atmosphere is sintering in air.

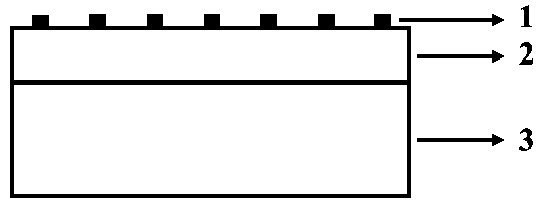

[0044] (2) Treatment of the substrate

[0045] 0.7%Nb-SrTiO with (100) orientation 3 For a single crystal substrate, the substrate is ultrasonically cleaned with acetone and absolute ethanol in sequence, rinsed with deionized water, dried with high-purity nitrogen, fixed on the sample tray with silver paste, and put the sample tray into the vacuum coating chamber on the sample tray rack in the chamber, close the vacuum chamber, an...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that the temperature of the substrate in step (3) is 650°C. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0054] The difference between this embodiment and embodiment 1 is that the distance between the substrate and the target in step (3) is 45 mm. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com