Method for absorbing residual fumigant sulfuryl fluoride by using ionic liquid composite bio-based solvent

An ionic liquid and solvent absorption technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high viscosity, unreported fumigant sulfuryl fluoride tail gas treatment, low vapor pressure, etc., and achieves large absorption capacity. , The effect of stable performance and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

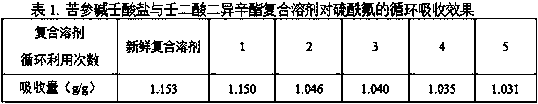

Embodiment 1

[0019] 1) Put 10g of composite solvent (made by uniformly mixing matrine nonanoate and diisooctyl azelate at a molar ratio of 1:1) into an absorption bottle, control the absorption temperature at 20°C, and use 30ml / min The flow rate is to feed sulfuryl fluoride gas into the absorption bottle; the weight of the absorption bottle is weighed every 5 minutes until the constant weight (at this time, the composite solvent is saturated with sulfuryl fluoride gas), and the final concentration of the composite solvent on sulfuryl fluoride is obtained. The absorption capacity is 1.153g sulfuryl fluoride / g composite solvent;

[0020] 2) Transfer the above saturated composite solvent into a 50ml single-mouth bottle (the single-mouth bottle is heated in a water bath, and the opening of the one-mouth bottle is connected to a water pump for vacuuming), and desorbed at a temperature of 70°C and an absolute pressure of 500Pa The operation is to desorb the sulfuryl fluoride absorbed in the comp...

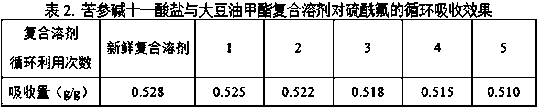

Embodiment 2

[0023] 1) Put 10g of composite solvent (made by uniformly mixing matrine undecanoate and soybean oil methyl ester at a molar ratio of 1:3) into an absorption bottle, control the absorption temperature at 40°C, and flow to the Feed sulfuryl fluoride gas into the absorbing bottle; weigh the weight of the absorbing bottle every 5 minutes until constant weight, and obtain the final absorption of sulfuryl fluoride by the composite solvent to be 0.528g sulfuryl fluoride / g composite solvent;

[0024] 2) Transfer the above saturated composite solvent into a 50ml one-mouth bottle (the one-mouth bottle is heated in a water bath, and the opening of the one-mouth bottle is connected to a water pump for vacuuming), and desorbed at a temperature of 70°C and an absolute pressure of 1000Pa The operation is to desorb the sulfuryl fluoride absorbed in the composite solvent to obtain the regenerated composite solvent, and then continue to apply it to the next absorption process, so as to recycle ...

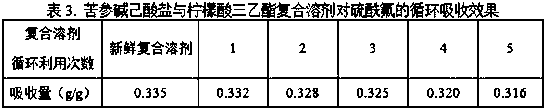

Embodiment 3

[0027] 1) Put 10g of compound solvent (made by uniformly mixing matrine caproate and triethyl citrate at a molar ratio of 1:7) into an absorption bottle, control the absorption temperature at 50°C, and flow to the Feed sulfuryl fluoride gas into the absorption bottle; weigh the weight of the absorption bottle every 5 minutes until constant weight, and obtain the final absorption of sulfuryl fluoride by the composite solvent to be 0.335g sulfuryl fluoride / g composite solvent;

[0028] 2) Transfer the above-mentioned saturated composite solvent into a 50ml single-mouth bottle (the single-mouth bottle is heated in a water bath, and the opening of the one-mouth bottle is connected to a water pump for vacuuming), and desorbed at a temperature of 80°C and an absolute pressure of 1500Pa The operation is to desorb the sulfuryl fluoride absorbed in the composite solvent to obtain the regenerated composite solvent, and then continue to apply it to the next absorption process, so as to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com