Preparation method of electron beam sensitive brittle material transmission electron microscope sample

A technology for transmission electron microscope samples and brittle materials, which is applied in the field of electron beam-sensitive brittle material transmission electron microscope sample preparation, can solve the problems of material surface temperature rise, microstructure damage, microstructure damage, etc., to reduce the bonding temperature and increase the electrical conductivity. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a TEM sample of an electron beam-sensitive brittle material. In this embodiment, it is specifically used for preparing a TEM sample 4 of geological minerals. Specifically include the following steps:

[0036] Step 1. Prepare thin-section samples.

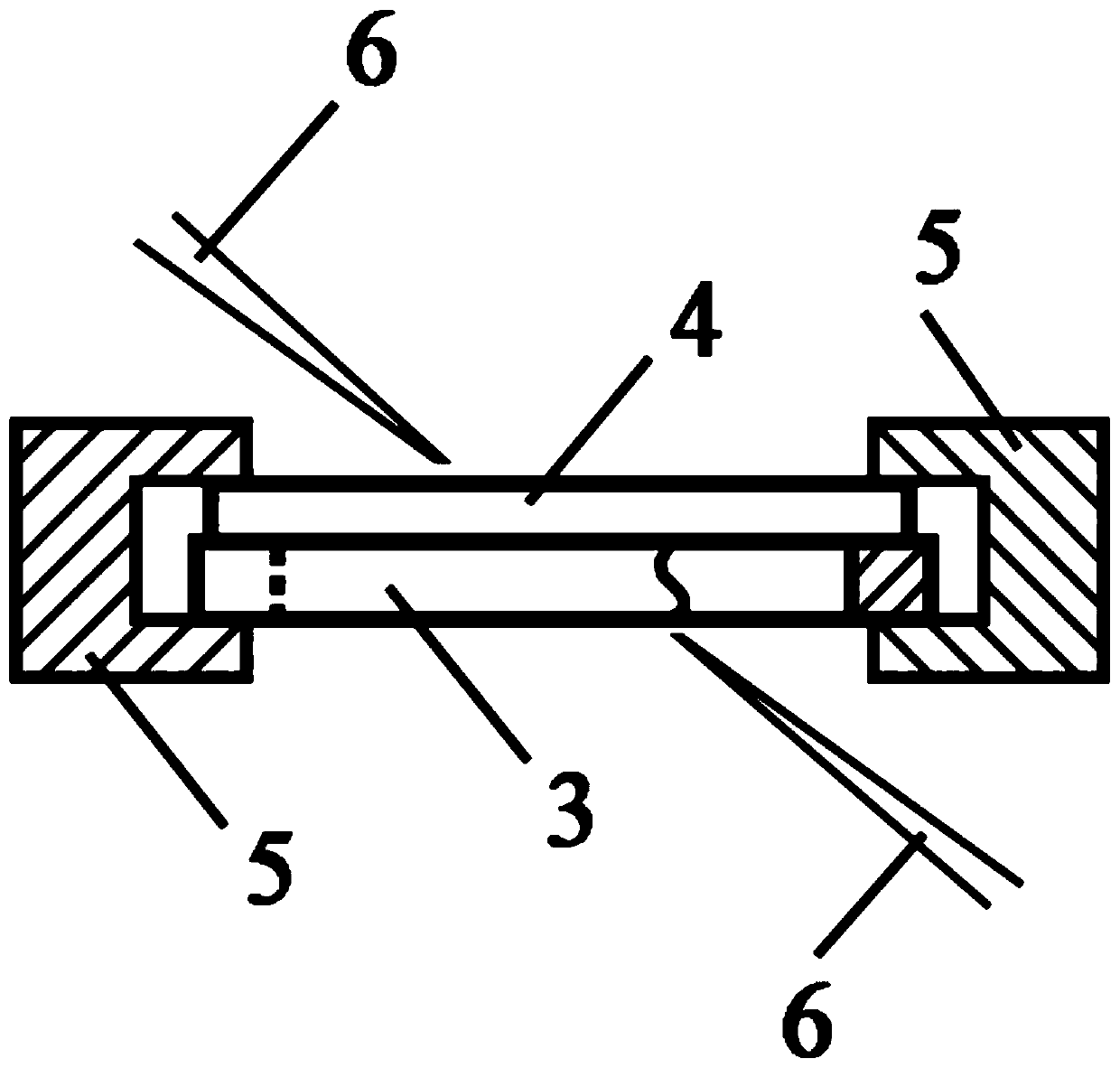

[0037] Select a piece of metastable geological aragonite, cut the sample into 0.5cm*0.5cm block samples with a hacksaw, and then cut 0.2mm to 0.4mm thick samples from the block sample with a water-cooled low-speed diamond cutter. Thin slice sample 4. Preferably, the thickness of the sample 4 cut out in this application is 0.3mm.

[0038] Step 2. Pre-thinning the thin slice sample by water milling.

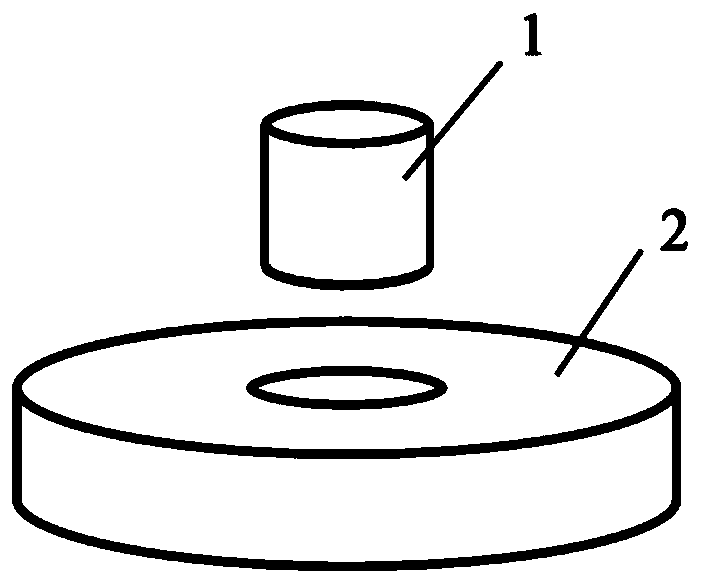

[0039] In this embodiment, specifically, the thin slice sample is bonded to the sample preparation mold for front and back grinding. Such as figure 1 Shown is a schematic diagram of the sample preparation mold used in this embodiment. The sample preparation mold is divided into an inner mold 1 and an ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com