A kind of preparation technology and detection method of microcapsule toughened and reinforced polypropylene composite material

A composite material and preparation process technology, which can be used in the analysis of materials, the use of stable tension/pressure to test the strength of materials, and measurement devices. It can solve the problems of poor low temperature impact resistance, easy aging, etc. The effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

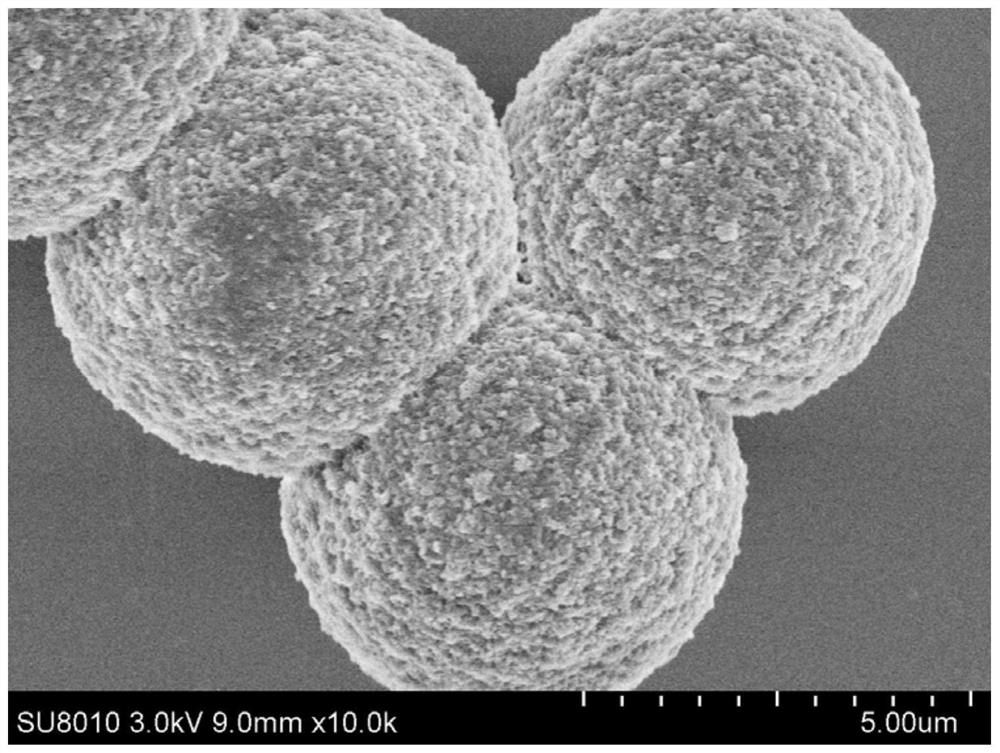

[0051] Preparation of ST-UF microcapsules:

[0052] 1) Weigh urea and formaldehyde solution according to the mass ratio of 10:18, add both into the flask, adjust pH=8 with triethanolamine, then put the flask into a constant temperature water bath at 74°C, stir and react for 1h, obtain capsule wall prepolymer;

[0053] 2) According to the mass parts ratio, take by weighing 100 parts of styrene, 37 parts of epoxy resin, 4 parts of acetone and 39 parts of tributyl phosphate, add in the three-necked flask and stir well, add 188 parts of 1% Twelve Aqueous sodium alkyl benzene sulfonate solution, 2 parts of n-octanol, and stirring continuously for 27 minutes at 30°C and 750rpm to form a stable oil-in-water (O / W) emulsified solution, namely the core material emulsion;

[0054] 3) Capsule wall coating capsule core: add the solution of capsule wall prepolymer prepared in 1) into the core material emulsion under stirring condition, and adjust the pH=3 of the system with dilute H2SO4, a...

Embodiment 2

[0061] Preparation of ST-UF microcapsules:

[0062] 1) Weigh urea and formaldehyde solution according to the mass ratio of 10:21, add both into the flask, adjust pH=7 with triethanolamine, then put the flask into a constant temperature water bath at 73°C, stir and react for 1h, obtain capsule wall prepolymer;

[0063] 2) According to the mass parts ratio, weigh 100 parts of styrene, 30 parts of epoxy resin, 5 parts of acetone and 38 parts of tributyl phosphate, add them into the three-necked flask and stir well, add 185 parts of 1% Twelve Aqueous sodium alkyl benzene sulfonate solution, 2.5 parts of n-octanol, and continued stirring for 26 minutes at 30 ° C and 500 rpm to form a stable oil-in-water (O / W) emulsified solution, that is, the core material emulsion;

[0064] 3) Capsule wall coating capsule core: add the solution of capsule wall prepolymer prepared in 1) into the core material emulsion under stirring conditions, and adjust the pH=3 of the system with dilute H2SO4, ...

Embodiment 3

[0067] Preparation of ST-UF microcapsules:

[0068] 1) Weigh urea and formaldehyde solution according to the mass ratio of 10:20, add both into the flask, adjust pH=7 with triethanolamine, then put the flask into a constant temperature water bath at 75°C, stir and react for 1h, obtain capsule wall prepolymer;

[0069] 2) According to the mass parts ratio, take by weighing 100 parts of styrene, 35 parts of epoxy resin, 4 parts of acetone and 40 parts of tributyl phosphate, add them into the three-necked flask and stir well, add 190 parts of 1% Twelve Aqueous sodium alkyl benzene sulfonate solution, 2 parts of n-octanol, and stirring continuously for 27 min at 30°C and 600 rpm to form a stable oil-in-water (O / W) emulsified solution, that is, the core material emulsion;

[0070] 3) Capsule wall coating capsule core: add the capsule wall prepolymer solution prepared in 1) into the core material emulsion under stirring conditions, and adjust the pH=4 of the system with dilute H2SO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com