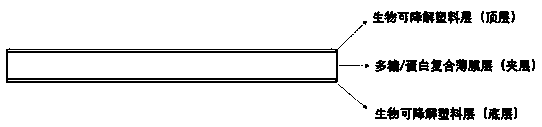

Polysaccharide/protein composite film with high barrier property and preparation method thereof

A composite film and high barrier technology, which is applied in the direction of chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of limited application, poor moisture barrier performance, mechanical properties, poor barrier performance, etc., and achieve excellent barrier performance, Improving barrier properties and performing well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A polysaccharide / protein composite film with high barrier performance and a preparation method thereof, the method comprising the steps of:

[0031] (1) Weigh 1.0 g of konjac glucomannan and 0.15 g of glycerol, add them to 100 mL of water, place in a 60 °C water bath, stir for 90 minutes, and rotate at 800 r / min to fully swell the konjac glucomannan to obtain konjac glucomannan Polysaccharide solution, set aside.

[0032] (2) Weigh 0.25 g of polycarbonate and 0.05 g of acetyl tributyl citrate into 5 mL of dichloromethane, stir at room temperature for 30 min with magnetic force to fully dissolve and disperse the polycarbonate, and obtain the bottom layer solution of polycarbonate. spare.

[0033] (3) Weigh 0.5 g of polycarbonate, 0.1 g of polylactic acid, and 0.12 g of acetyl tributyl citrate into 5 mL of dichloromethane, dissolve with magnetic stirring at room temperature, and stir for 30 min to fully dissolve and disperse the polycarbonate. A polycarbonate / polylactic...

Embodiment 2

[0038] A polysaccharide / protein composite film with high barrier performance and a preparation method thereof, the method comprising the steps of:

[0039] (1) Weigh 0.9 g of konjac glucomannan and 0.18 g of glycerol, add them to 100 mL of water, place in a 60 °C water bath, stir for 90 minutes, and rotate at 800 r / min to fully swell the konjac glucomannan to obtain konjac glucomannan polysaccharide solution.

[0040] (2) Weigh 0.1 g zein and 0.025 g span 80 into 20 mL of 80% ethanol solution, dissolve with magnetic stirring at room temperature, and stir for 30 min to fully dissolve and disperse zein to obtain a zein solution .

[0041] (3) Slowly add the zein solution in (2) to the konjac glucomannan solution in (1) to form a mixed solution, and stir in a water bath at 60 °C for 45 min at a speed of 1200 r / min to obtain konjac glucomannan / zein blend solution.

[0042] (4) Weigh 0.25 g of polycarbonate, 0.025 g of acetyl tributyl citrate and 0.025 g of dibutyl sebacate into ...

Embodiment 3

[0048] A polysaccharide / protein composite film with high barrier performance and a preparation method thereof, the method comprising the steps of:

[0049] (1) Weigh 1.0 g of konjac glucomannan and 0.20 g of glycerol, add them to 100 mL of water, place in a water bath at 60 °C, stir for 90 minutes, and rotate at 800 r / min to fully swell the konjac glucomannan to obtain konjac glucomannan polysaccharide solution.

[0050] (2) Weigh 0.3 g of gluten and 0.03 g of span 80 into 20 mL of pH 12 55% ethanol solution, dissolve with magnetic stirring at 60°C, and stir for 30 min to fully dissolve and disperse the gluten to obtain a gluten solution.

[0051] (3) Slowly add the glutenin solution in (2) to the konjac glucomannan solution in (1) to form a mixed solution, stir in a water bath at 60 °C for 30 min at a speed of 1200 r / min to obtain konjac glucomannan / glutenin Blend the solution.

[0052] (4) Weigh 0.25 g of polycarbonate, 0.025 g of acetyl tributyl citrate and 0.025 g of dib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com