A kind of preparation method of nano-gold doped deuterated foam microsphere

A technology of foam microspheres and nano-gold, which is applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of poor foam formability, low metal doping, and high processing difficulty, and achieve low difficulty, large specific surface area, The effect of excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of nano-gold doped deuterated foam microspheres, comprising the following steps:

[0030] Step 1. Add 300mg of deuterated p-divinylbenzene and 100mg of styrene into the reactor and mix evenly, then add 6mg of initiator and 3mL of organic solvent and stir, then add 20mg of 15nm gold nanoparticles, 6mg of dispersant and 60mL of water phase , under the protection of an inert atmosphere, stirred and reacted at 80°C for 1 hour, and formed foam pellets in the water phase; the initiator was azobisisobutyronitrile; the organic solvent was dibutyl phthalate; the The dispersant is poly(4-vinylphenol); the water phase is 5wt% polyethylene glycol aqueous solution;

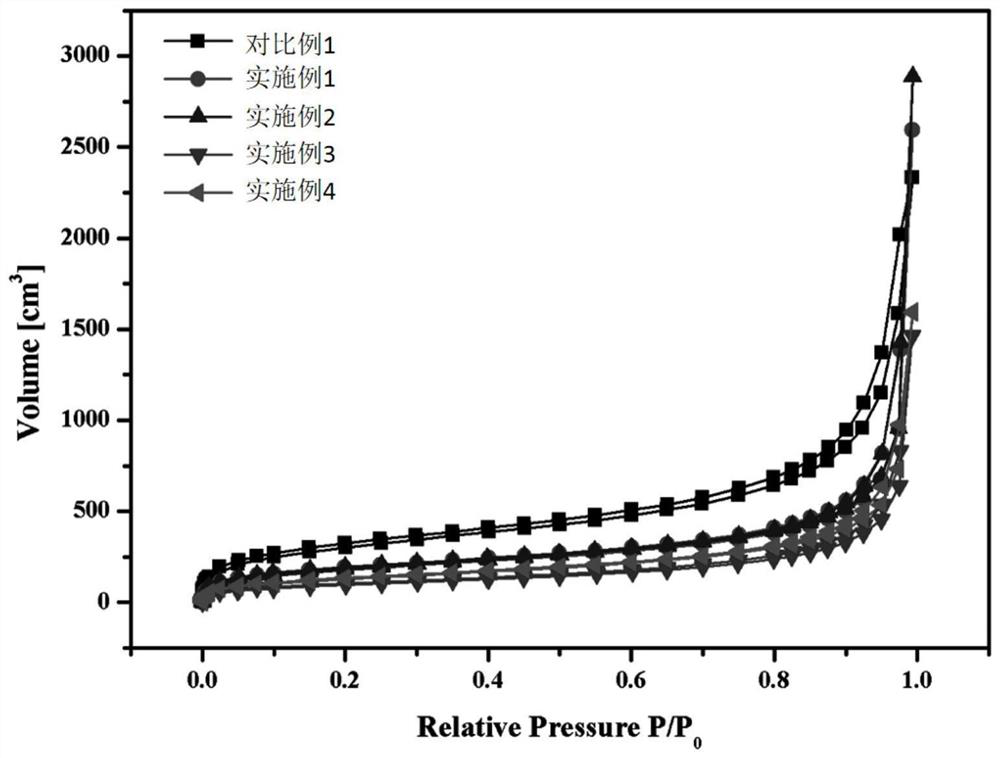

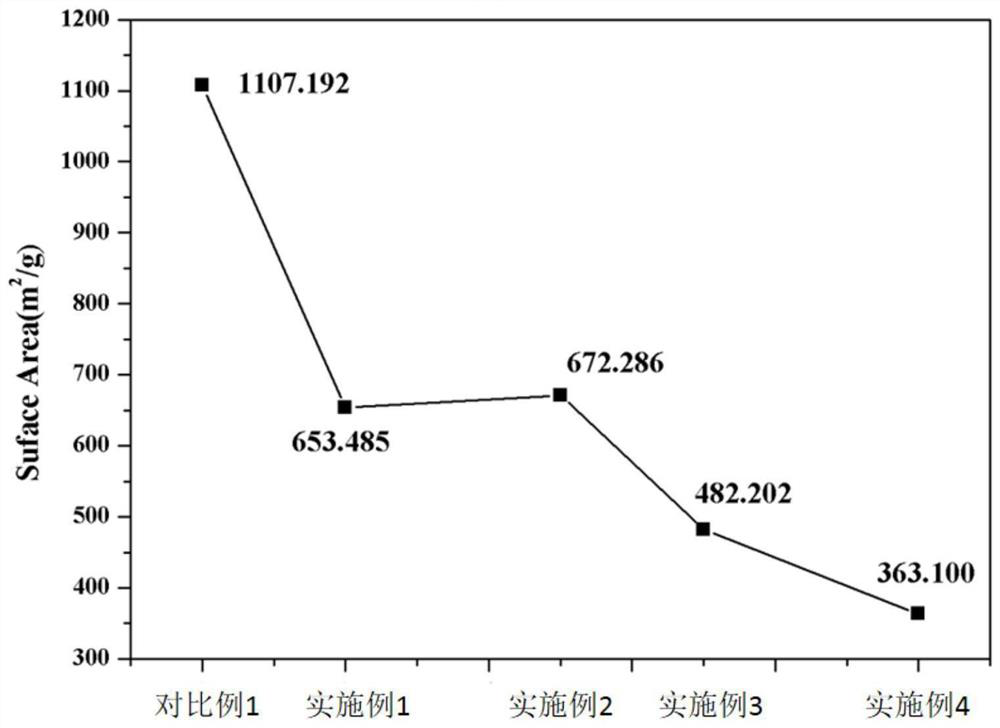

[0031] Step 2, separate the foam pellets in the water phase, and then use CO 2 Supercritical drying, the obtained foam skeleton material is deuterated p-divinylbenzene nano-gold doped deuterated foam microspheres; the specific surface area of the nano-gold doped deuterated foam microspheres prepa...

Embodiment 2

[0033] A preparation method of nano-gold doped deuterated foam microspheres, comprising the following steps:

[0034] Step 1. Add 300mg of deuterated p-divinylbenzene and 100mg of styrene into the reactor and mix evenly, then add 6mg of initiator and 3mL of organic solvent and stir, then add 20mg of 15nm gold nanoparticles, 15mg of dispersant and 60mL of water phase , under the protection of an inert atmosphere, stirred and reacted at 80°C for 1 hour, and formed foam pellets in the water phase; the initiator was azobisisobutyronitrile; the organic solvent was dibutyl phthalate; the The dispersant is poly(4-vinylphenol); the water phase is 5wt% polyethylene glycol aqueous solution;

[0035] Step 2, separate the foam pellets in the water phase, and then use CO 2 Supercritical drying is carried out to obtain nano-gold doped deuterated foam microspheres whose foam skeleton material is deuterated p-divinylbenzene. The specific surface area of the nano-gold doped deuterated foam...

Embodiment 3

[0037] A preparation method of nano-gold doped deuterated foam microspheres, comprising the following steps:

[0038] Step 1. Add 300mg of deuterated p-divinylbenzene and 100mg of styrene into the reactor and mix evenly, then add 6mg of initiator and 3mL of organic solvent and stir, then add 20mg of 15nm gold nanoparticles, 21mg of dispersant and 60mL of water phase , under the protection of an inert atmosphere, stirred and reacted at 80°C for 1 hour, and formed foam pellets in the water phase; the initiator was azobisisobutyronitrile; the organic solvent was dibutyl phthalate; the The dispersant is poly(4-vinylphenol); the water phase is 5wt% polyethylene glycol aqueous solution;

[0039] Step 2, separate the foam pellets in the water phase, and then use CO 2 Supercritical drying is carried out to obtain nano-gold doped deuterated foam microspheres whose foam skeleton material is deuterated p-divinylbenzene. The specific surface area of the nano-gold doped deuterated foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com