Platinum-carbon catalyst, preparation method thereof and application of platinum-carbon catalyst in fuel cell cathode catalyst

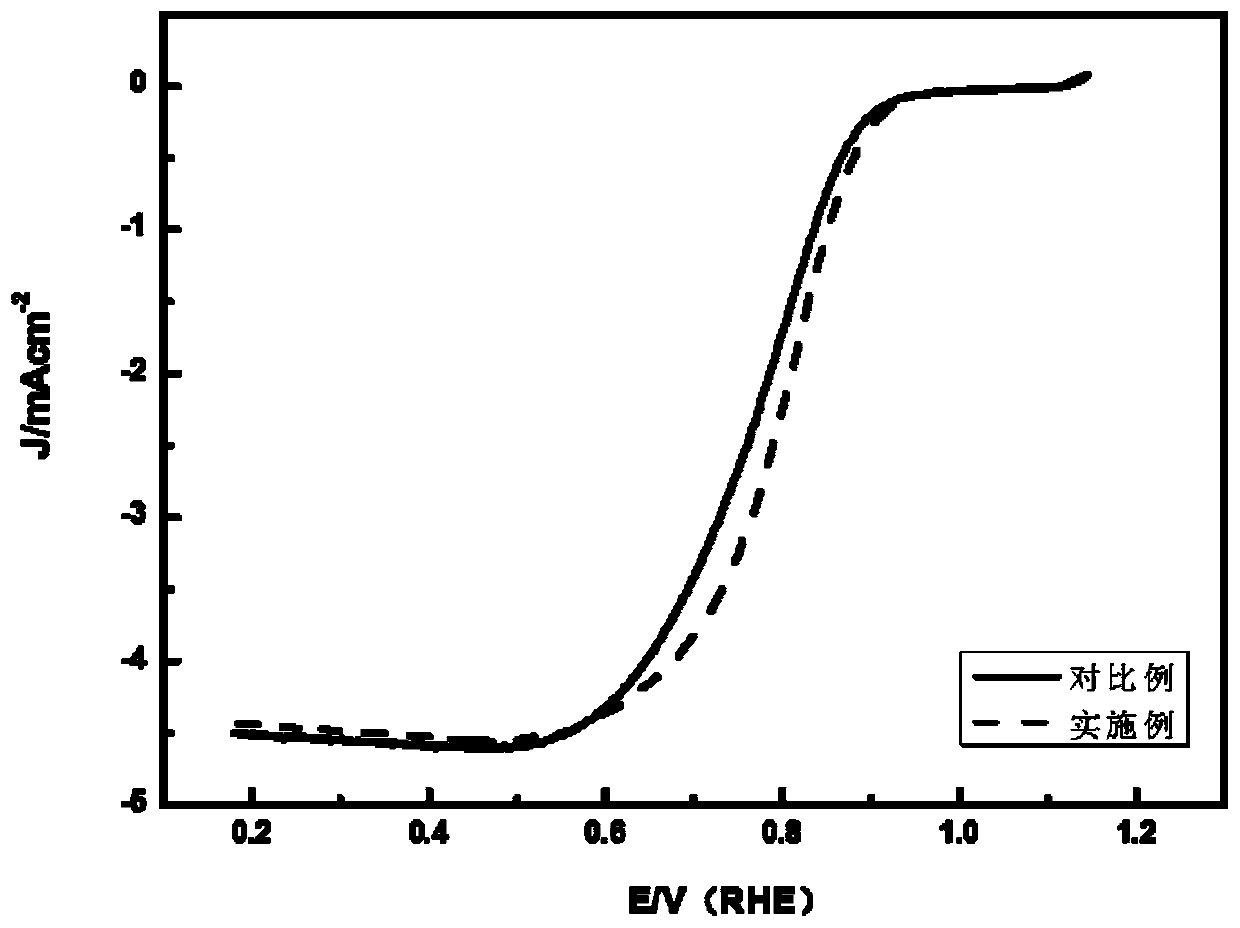

A platinum-carbon catalyst and hydrothermal carbonization technology are applied in its preparation, the application of fuel cell cathode catalysts, and the field of platinum-carbon catalysts, which can solve problems such as time-consuming, reduce pretreatment steps, are environmentally friendly, and have good ORR catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Put 8.2g of glucose into a 100ml beaker, add deionized water to make a 70ml solution, stir for 40min, add sodium bicarbonate solution dropwise to adjust to pH=8 while stirring.

[0061] 2. Transfer the above solution into a 100ml Teflon-lined stainless steel reactor for hydrothermal carbonization reaction at 180°C for 5h.

[0062] 3. After the liquid is naturally cooled, centrifuge and wash the solid repeatedly with deionized water and ethanol until the filtrate is clear.

[0063] 4. Dry the washed solid in a vacuum oven at 70°C for 10 hours to obtain a dry carbon support.

[0064] 5. Take 1.5g of glucose to make a 30ml solution, add 20ml of a solution containing 0.2g of chloroplatinic acid, and stir for 20min.

[0065] 6. Stir the mixed solution and heat it to 60°C and keep it warm for 30min. Take 0.3g of the carbon-loaded solution obtained in step 4 to prepare 20ml of suspension with absolute ethanol, add it to the above solution, stir for 20min, then raise the te...

Embodiment 2

[0070] 1. Take 7.5g of fructose and put it into a 100ml beaker, add deionized water to make a 70ml solution, stir for 40min, add dropwise oxalic acid solution to adjust to pH=5 while stirring.

[0071] 2. Transfer the above solution into a 100ml Teflon-lined stainless steel reactor for hydrothermal carbonization reaction at 170°C for 8h.

[0072] 3. After the liquid is naturally cooled, centrifuge and wash the solid repeatedly with deionized water and ethanol until the filtrate is clear.

[0073] 4. Dry the washed filter cake in a vacuum oven at 80°C for 8 hours to obtain a dry carbon load.

[0074] 5. Take 4.2g of glucose to make a 70ml solution, add 20ml of a solution containing 0.63g of potassium chloroplatinite, and stir for 20min.

[0075] 6. Stir and heat the mixed solution to 60°C and keep it warm for 10min. Take 0.2g of the carbon-loaded propanol obtained in step 4 to prepare 10ml of suspension, add it to the above solution, stir for 10min, then raise the temperature ...

Embodiment 3

[0080] 1. Put 8g of sucrose into a 100ml beaker, add deionized water to make a 70ml solution, stir for 40min, add acetic acid dropwise to adjust to pH=6 while stirring.

[0081] 2. Transfer the above solution into a 100ml polytetrafluoroethylene-lined stainless steel reactor for hydrothermal carbonization reaction at 160°C for 12h.

[0082] 3. After the liquid is naturally cooled, centrifuge and wash the solid repeatedly with deionized water and ethanol until the filtrate is clear.

[0083] 4. Dry the washed solid in a vacuum oven at 90°C for 6 hours to obtain a dry carbon support.

[0084] 5. Take 2.8g of glucose to make a 70ml solution, add 20ml of a solution containing 0.5g of potassium chloroplatinate, and stir for 20min.

[0085] 6. Stir the mixed solution and heat it to 60°C and keep it warm for 20min. Take 0.3g of the carbon carrier obtained in step 4 and prepare 20ml of suspension with isopropanol, add it to the above solution, stir for 30min, then raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com