Lithium ion positive electrode coating and lithium ion battery

A lithium-ion battery and lithium-ion technology, applied in the coating of electrode collectors, secondary batteries, battery electrodes, etc., can solve the problem of reduced battery discharge capacity, achieve reduced resistance, high lithium salt concentration, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of lithium ion cathode coating 12, comprises the following steps:

[0042] 1) Mix and stir the conductive binder and deionized water, and add the conductive agent;

[0043] 2) adding the positive electrode active material for mixing and stirring, adding deionized water to make a lithium ion positive electrode slurry with a solid content of 48-72%;

[0044] 3) Coating the lithium ion positive electrode slurry obtained in step 2) on the positive electrode current collector 14, and drying in a manner of gradient temperature rise at 50-110° C., to obtain the lithium ion positive electrode coating 12 . In order to improve the processing performance of the positive electrode slurry, a mixture of deionized water and NMP can be selected as the pulping solvent, and the amount of NMP added is 0-5% of the dry powder weight of the positive electrode slurry.

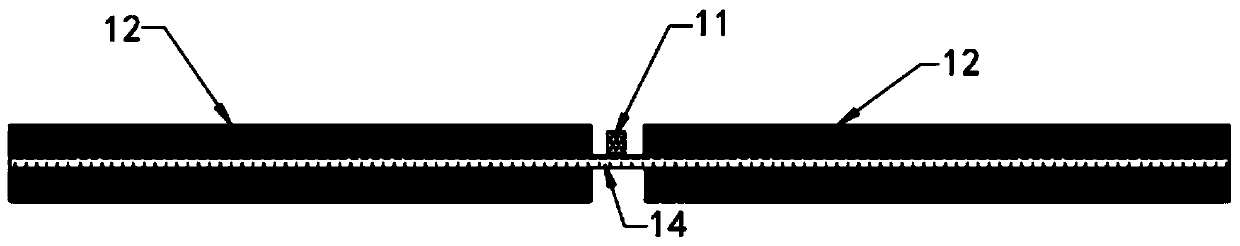

[0045] A lithium-ion battery, such as figure 1 As shown, the above-mentioned lithium-ion battery po...

Embodiment 1

[0053] The ratio of the lithium ion positive electrode coating 12 is: positive electrode active material: conductive binder: conductive agent = 95.0:4.0:1.0. The electrolyte ratio is: EC:EMC:DMC=20:10:65, the concentration of LiPF6 is 1.4mol / L, 0.1%FEC, 0.2%FPS, 1%ES, 1%LiFSI and 0.2%DTD.

[0054] Preparation method of conductive adhesive:

[0055] 1) Acrylic acid monomers are polymerized to generate propylene-based multi-polymers, and 0.2mol / L lithium hydroxide is added, wherein the molar ratio of propylene-based multi-polymers to lithium hydroxide is 1:0.02 to generate carboxylithium and hydroxylithium functional groups ;

[0056] 2) Add carbon nanotubes to the acrylic multi-polymer polymer obtained in step 1), the weight ratio of the acrylic multi-polymer and carbon nanotubes is 99.5:0.5, and after the two are ultrasonically mixed at 40°C, the acrylic multi-polymer The molecular chains of the carbon nanotubes and the molecular chains of the carbon nanotubes are fully open...

Embodiment 2

[0066] The ratio of the lithium ion positive electrode coating 12 is: positive electrode active material: conductive binder: conductive agent = 95.0:4.0:1.0. The electrolyte ratio is: EC:EMC:DMC=25:10:65, LiPF 6 The concentration is 1.4mol / L, 1.2% FEC, 0.8% FPS, 1% ES, 1% LiFSI, 0.7% DTD.

[0067] Preparation method of conductive adhesive:

[0068] 1) Acrylic acid monomers are polymerized to generate propylene-based multi-polymers, and 0.3mol / L lithium hydroxide is added. The molar ratio of propylene-based multi-polymers to lithium hydroxide is 1:0.03 to generate carboxylithium and hydroxylithium functional groups ;

[0069] 2) Add carbon nanotubes to the acrylic multi-polymer polymer obtained in step 1), and the weight ratio of the acrylic multi-polymer to carbon nanotubes is 99.5:0.5. After the two are ultrasonically mixed at 40-60 DEG C, the molecular chains of the acrylic polypolymer and the carbon nanotube molecular chains are fully opened, and the two are fully mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com