Silicon wafer surface grinding device

A silicon wafer surface and grinding device technology, which is applied in the direction of grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of reduced workpiece precision, poor working environment, environmental pollution, etc., and achieve the goals of increased productivity, convenient operation, and improved polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the essence of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

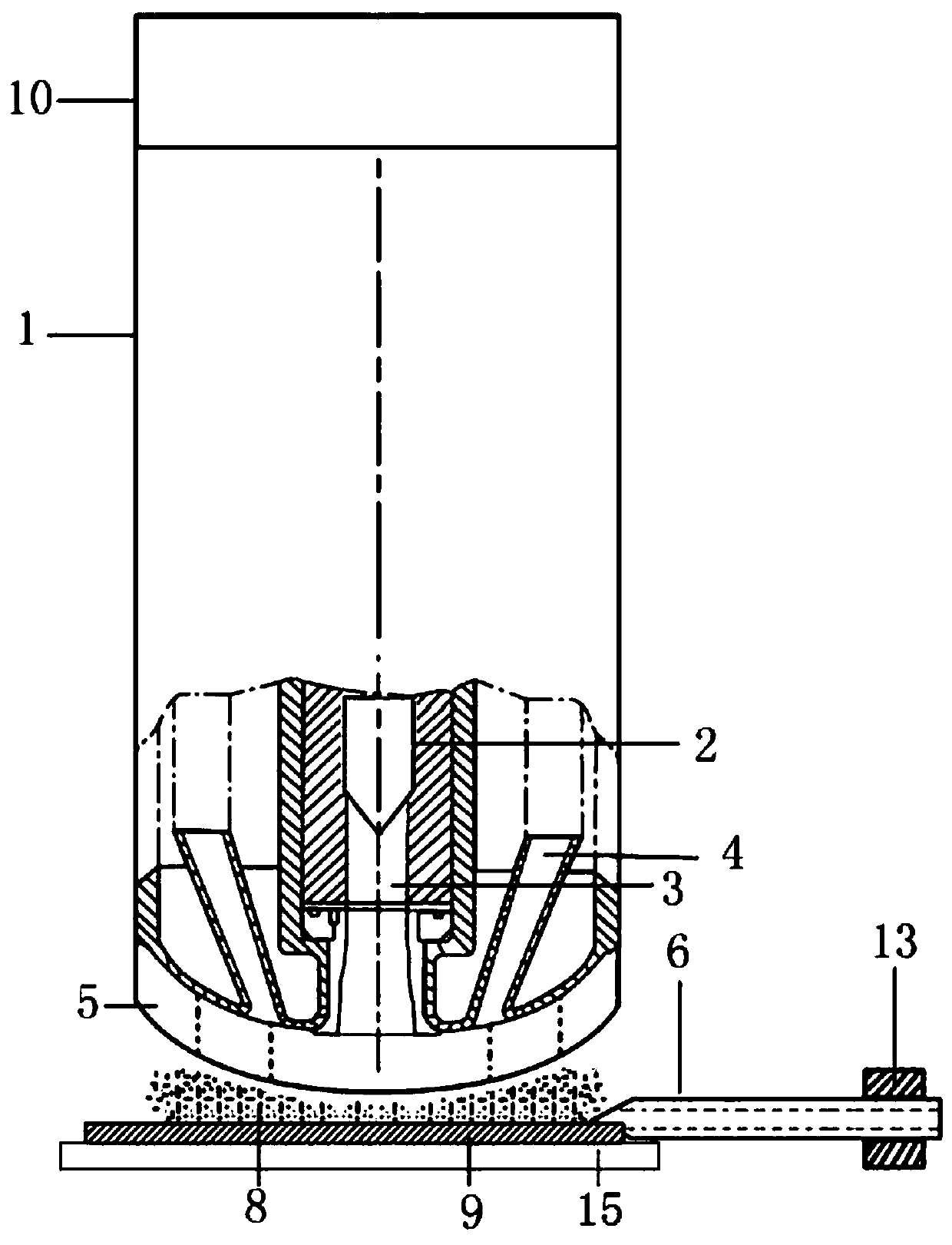

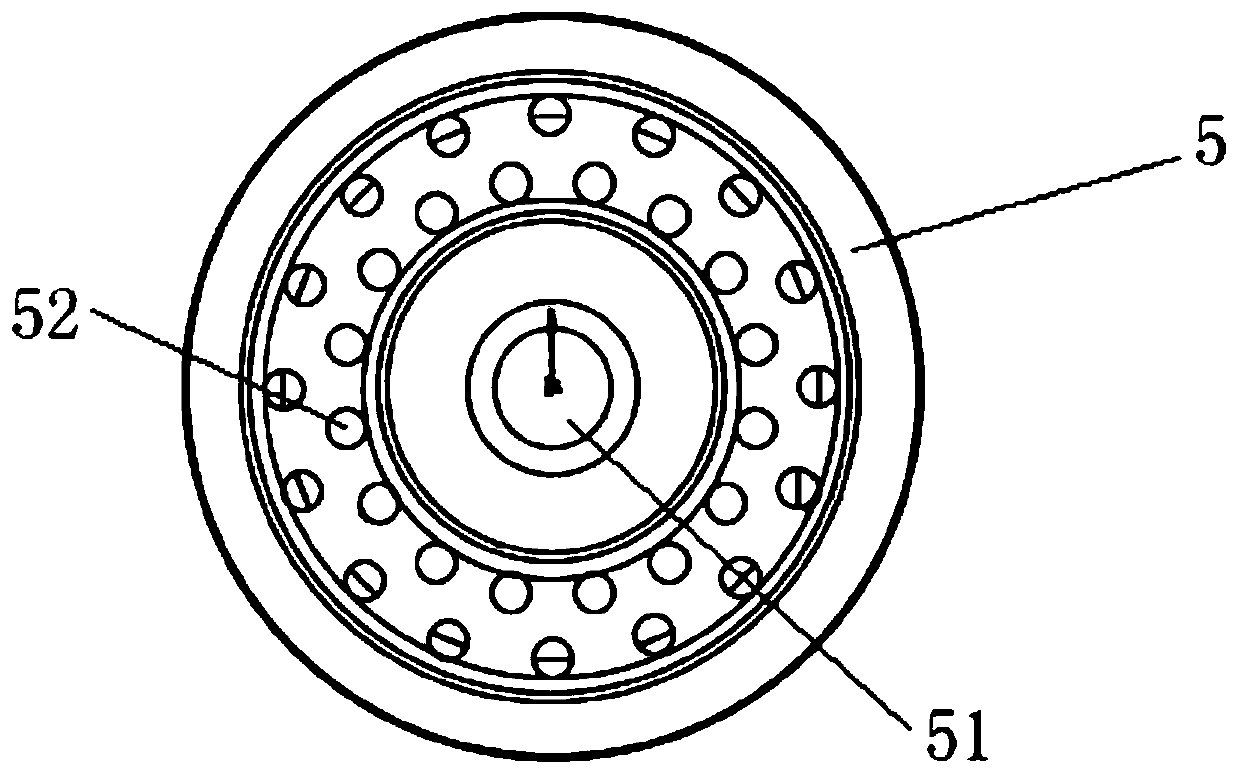

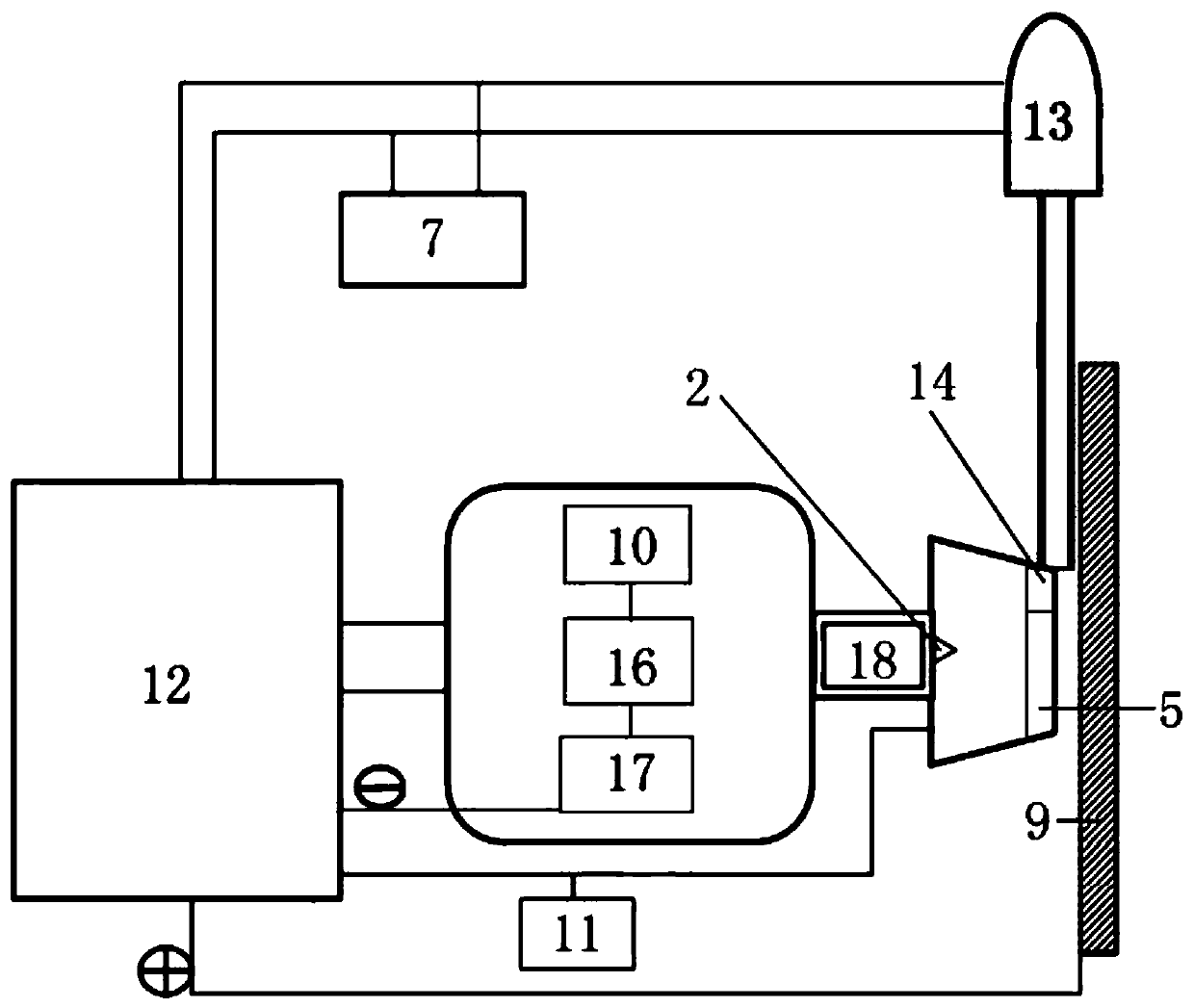

[0017] The present invention is applicable to the technical field of surface treatment, and is especially suitable for grinding the surface of a silicon wafer. The structure of a specific embodiment is as follows figure 1 As shown, it includes a plasma spray gun 1, a servo motor 10, a laser ranging component, a deionized water supply structure and an ultrasonic enhancement structure. The servo motor 10 is connected with the plasma spray gun 1, and the servo motor 10 drives the plasma sub-spray gun to perform axial rotation and feed movement. The plasma torch 1 comprises a plasma channel 4 , a nozzle 5 , a plasma torch control system 16 and a plasma generator 17 . The plasma torch control system 16 is located inside the plasma torch 1 and communicated with the plasma generator 17 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com