Cerium-doped tungsten phosphide submicron sphere composite material, preparation method and application thereof

A composite material, sub-micron technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as the improvement of electrical conductivity and catalytic activity, and achieve enhanced adsorption and desorption capabilities. The effect of strong performance and improved hydrogen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

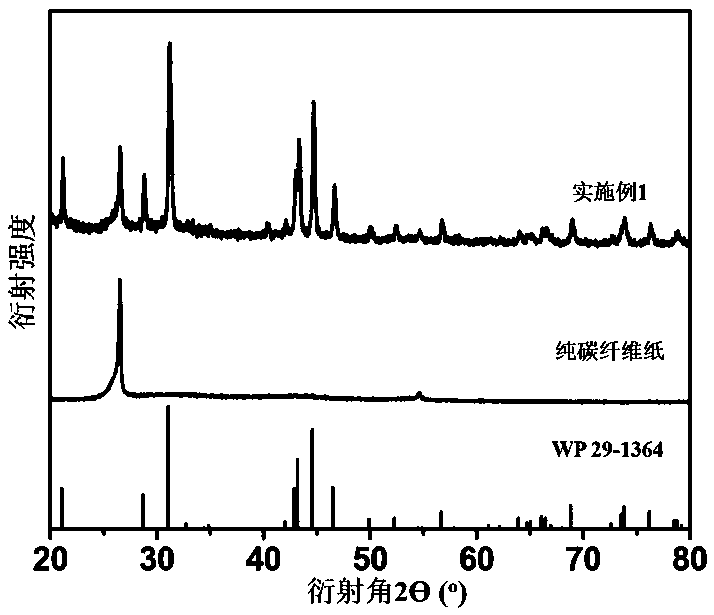

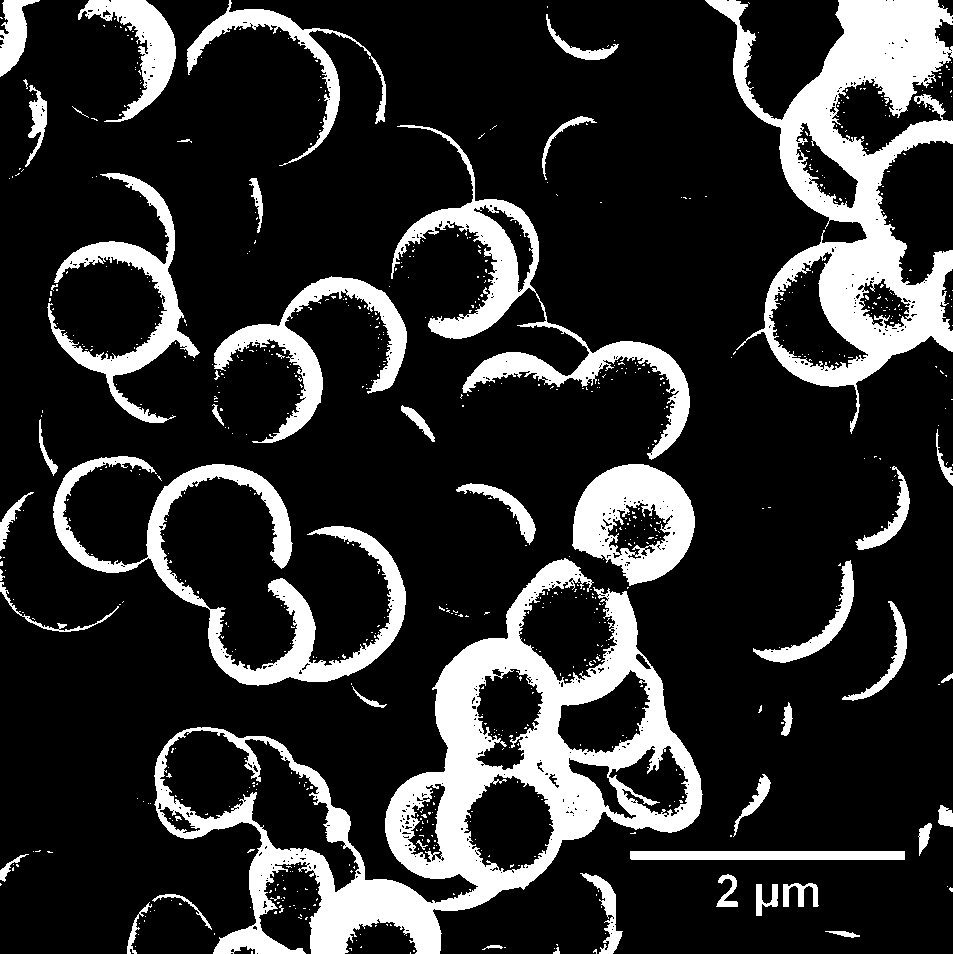

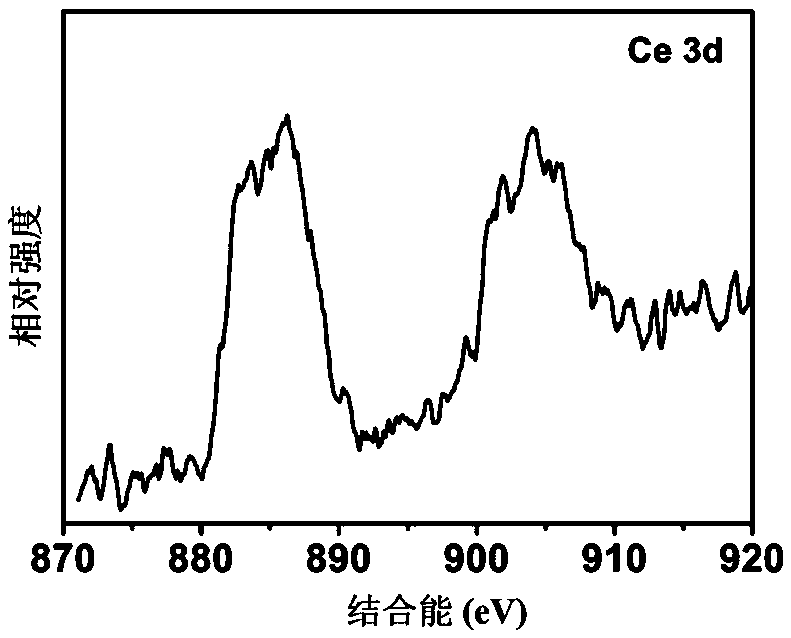

Embodiment 1

[0038] Dissolve 0.24 g of tungsten chloride in 30 mL of absolute ethanol to obtain an ethanol solution of tungsten chloride; then add 0.010 g of cerium chloride to the above solution, so that the molar ratio of cerium in the entire tungsten and cerium elements is 6 %, stirred and dissolved to obtain a yellow transparent mixed solution; the mixed solution was transferred to the reaction kettle, and carbon fiber paper (2×5 cm 2 ) placed against the wall, heated to 200 °C, and reacted for 10 h; after that, the reactor was cooled naturally, the carbon fiber paper was taken out, rinsed with absolute ethanol, and vacuum-dried at 60 °C for 12 h to obtain carbon fiber paper loaded with cerium doped Tungsten oxide submicron sphere samples. The carbon fiber paper-loaded cerium-doped tungsten oxide submicron sphere sample and 4 g sodium hypophosphite were placed together in a tube furnace, where the sodium hypophosphite was placed at the upper tuyere, and the temperature was 10 °C under ...

Embodiment 2

[0043] Dissolve 0.24 g of tungsten chloride in 30 mL of absolute ethanol to obtain an ethanol solution of tungsten chloride; then add 0.017 g of cerium chloride to the above solution, so that the molar ratio of cerium in the entire tungsten and cerium elements is 10 %, stirred and dissolved to obtain a yellow transparent mixed solution; the mixed solution was transferred to the reaction kettle, and carbon fiber paper (2×5 cm 2) placed against the wall, heated to 200 °C, and reacted for 10 h; the reactor was cooled naturally, the carbon fiber paper was taken out, rinsed with absolute ethanol, and vacuum-dried at 60 °C for 12 h to obtain carbon fiber paper loaded with cerium-doped tungsten oxide submicron Ball samples. The carbon fiber paper-loaded cerium-doped tungsten oxide submicron sphere sample and 4 g sodium hypophosphite were placed together in a tube furnace, where the sodium hypophosphite was placed at the upper tuyere, and the temperature was 10 °C under argon (flow ra...

Embodiment 3

[0045] Dissolve 0.24 g of tungsten chloride in 30 mL of absolute ethanol to obtain an ethanol solution of tungsten chloride; then add 0.013 g of cerium chloride to the above solution, so that the molar ratio of cerium in the entire tungsten and cerium elements is 8 %, stirred and dissolved to obtain a yellow transparent mixed solution; the mixed solution was transferred to the reaction kettle, and carbon fiber paper (2×5 cm 2 ) placed against the wall, heated to 200 °C, and reacted for 10 h; the reactor was cooled naturally, the carbon fiber paper was taken out, rinsed with absolute ethanol, and dried in vacuum at 60 °C for 12 h to obtain carbon fiber paper-loaded cerium-doped tungsten oxide submicron spheres sample. The carbon fiber paper-loaded cerium-doped tungsten oxide submicron sphere sample and 4 g sodium hypophosphite were placed together in a tube furnace, where the sodium hypophosphite was placed at the upper tuyere, and the temperature was 10 °C under argon (flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com