A low-temperature curing type high foaming ratio automotive primer and preparation method thereof

A curing-type, high-foaming technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of high curing conditions, output, energy and cost, and meet the requirements of elongation at break and Effect of tensile strength, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

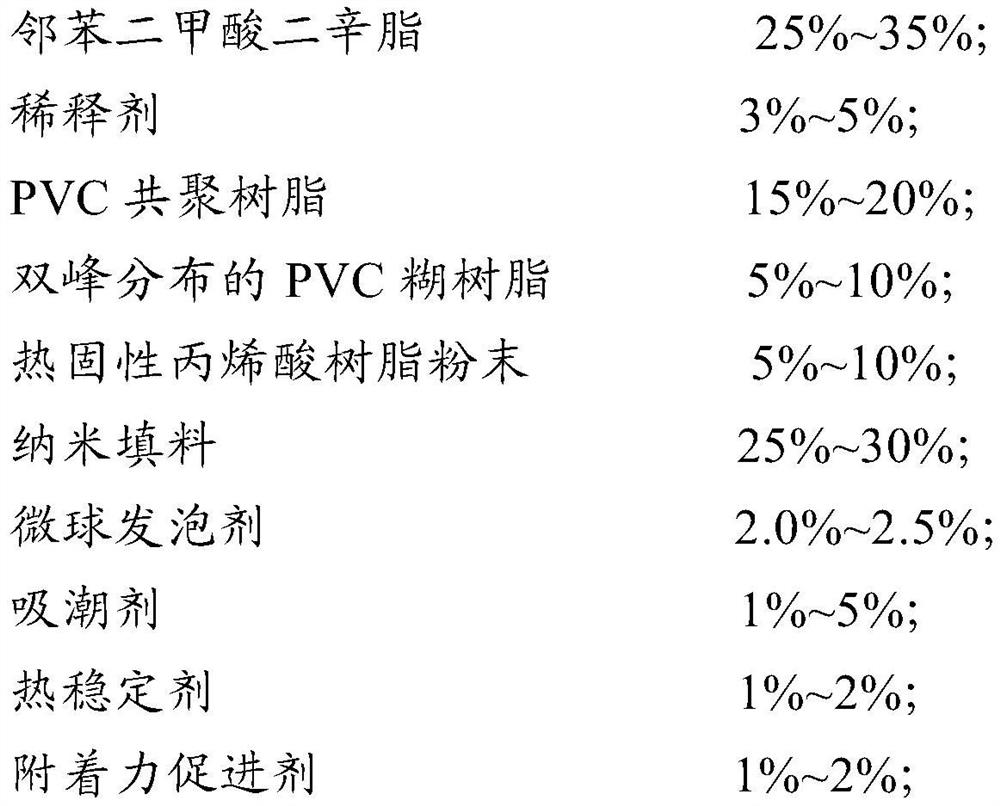

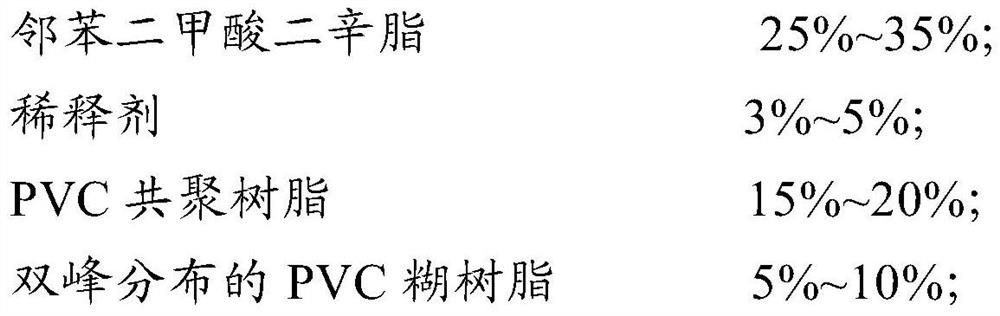

[0028] This embodiment provides a low-temperature curing type high expansion ratio automotive primer, and its preparation process is as follows:

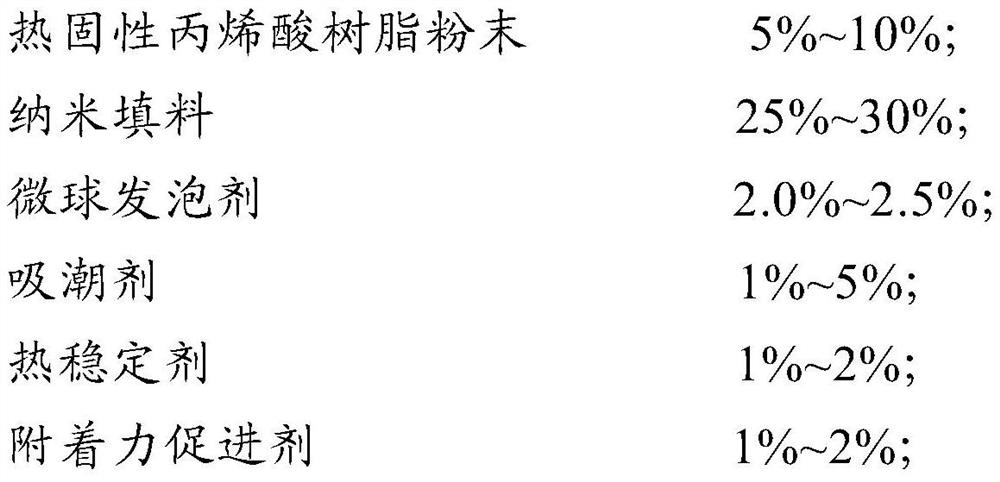

[0029] (1) Mixing: Add 300g of diluent, 2900g of dioctyl phthalate and 150g of low-molecular polyamide adhesion promoter with high amine value (250mgKOH / g) into the stirring tank, stir at 500rpm for 3 minutes; then add suction Moisture agent 400g, heat stabilizer 150g, PVC paste resin with bimodal distribution 800g, vinyl chloride-vinyl acetate copolymer paste resin 1500g, thermosetting acrylic resin powder 700g, stir at 1200rpm for 4 minutes; then add nano-calcium carbonate filler 2890g, Akzo Bell's 043DU80 microsphere foaming agent 210g, stirred at 1200rpm for 3 minutes;

[0030] (2) Grinding: the evenly stirred material is passed through a three-roll mill;

[0031] (3) Placement: After the material is ground, it is pumped into a vacuum tank for 24 hours to stabilize the viscosity of the product;

[0032] (4) Viscosity adjustmen...

Embodiment 2

[0037] This embodiment provides a low-temperature curing type high expansion ratio automotive primer, and its preparation process is as follows:

[0038] (1) Mixing: Add 300g of diluent, 3200g of dioctyl phthalate and 100g of low-molecular polyamide adhesion promoter with high amine value (250mgKOH / g) into the stirring tank, stir at 500rpm for 3 minutes; then add suction Moisture agent 100g, heat stabilizer 100g, PVC paste resin with bimodal distribution 500g, vinyl chloride-vinyl acetate copolymer paste resin 2000g, thermosetting acrylic resin powder 500g, stir at 1200rpm for 4 minutes; then add nano-calcium carbonate filler 3000g, Akzo Bell's 043DU80 microsphere foaming agent 200g, stirred at 1200rpm for 3 minutes;

[0039] (2) Grinding: the evenly stirred material is passed through a three-roll mill;

[0040] (3) Placement: After the material is ground, it is pumped into a vacuum tank for 24 hours to stabilize the viscosity of the product;

[0041] (4) Viscosity adjustmen...

Embodiment 3

[0046] This embodiment provides a low-temperature curing type high expansion ratio automotive primer, and its preparation process is as follows:

[0047] (1) Mixing: Add 500g of diluent, 2500g of dioctyl phthalate and 200g of low molecular weight polyamide adhesion promoter with high amine value (250mgKOH / g) into the stirring tank, stir at 500rpm for 3 minutes; then add suction Moisture agent 500g, heat stabilizer 100g, bimodal PVC paste resin 1000g, vinyl chloride-vinyl acetate copolymer paste resin 1500g, thermosetting acrylic resin powder 1000g, stir at 1200rpm for 4 minutes; then add nano calcium carbonate filler 2500g, Akzo Bell's 043DU80 microsphere foaming agent 200g, stirred at 1200rpm for 3 minutes;

[0048] (2) Grinding: the evenly stirred material is passed through a three-roll mill;

[0049] (3) Placement: After the material is ground, it is pumped into a vacuum tank for 24 hours to stabilize the viscosity of the product;

[0050] (4) Viscosity adjustment: After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| foaming ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com