Mixed rare earth sintered neodymium-iron-boron permanent magnet and preparation method thereof

A mixed rare earth, NdFeB technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the negative impact of NdFeB magnets' remanence and coercivity, and the magnetic properties are difficult to meet the application. requirements and other issues, to achieve the effect of being conducive to comprehensive utilization, promoting comprehensive utilization, and reducing industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of mixed rare earth sintered NdFeB permanent magnet, the specific steps are as follows:

[0027] Step 1: Follow High H A Re-Fe-B alloy and low H A The components of the mixed rare earth alloys are dosed separately, and the quick-setting strips of the two alloys with a thickness of 0.2-0.5mm are respectively obtained by using the quick-setting strip technology, and the quick-setting strips of the two alloys are hydrogen crushed and jet milled Make magnetic powder with an average particle size of 2-5 μm;

[0028] Step 2: Mix the two kinds of magnetic powders according to the ratio under the protection of nitrogen, mix them in the mixing tank for 1-3 hours, and after mixing evenly, they are oriented and formed under a magnetic field of 1.5T-2T, and then cold isostatic pressed at 200MPa to produce Blank;

[0029] Step 3: Put the green body in a vacuum sintering furnace for sintering, the sintering temperature is 1000-1150°C, and keep it warm for 1-...

Embodiment 1

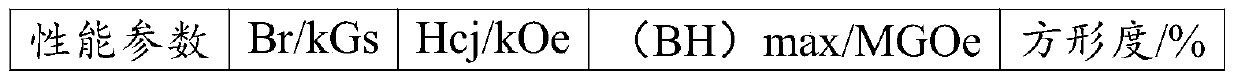

[0042] The mass percentage is (MM 0.625 Re 0.375 ) 30 Fe bal B 1 Cu 0.1 al 0.2 and (PrNd) 30 Fe bal B 1 Cu 0.1 al 0.5 Zr 0.1 The main phase alloys are separately batched, and the process flow of rapid solidification, hydrogen crushing and jet milling is used to prepare powders with an average particle size of less than 3.5 μm. (MM) at a mass ratio of 3:7 30 Fe bal B 1 Cu 0.1 al 0.2 and (PrNd) 30 Fe bal B 1 Cu 0.1 al 0.5 Zr 0.1 After adding lubricant and anti-oxidant to the magnetic powder and mixing them evenly, the magnetic powder is oriented and shaped under a 2T magnetic field under the protection of nitrogen, and is made into a green body by 200MPa cold isostatic pressing. Put the green body into a vacuum sintering furnace, sinter and hold at 1060°C for 4 hours; then temper at 900°C for 3 hours, then perform a low-temperature tempering treatment at 540°C for 2 hours, and perform a secondary low-temperature tempering at 500°C Processing 2h. The magne...

Embodiment 2

[0048] The mass percentage is (MM) 30 Fe bal B 1 Cu 0.1 al 0.2 and (PrNd) 30 Fe bal B 1 Cu 0.1 al 0.5 Zr 0.1 The main phase alloys are separately batched, and the process flow of rapid solidification, hydrogen crushing and jet milling is used to prepare powders with an average particle size of less than 3.5 μm. (MM) at a mass ratio of 3:13 30 Fe bal B 1 Cu 0.1 al 0.2 and (PrNd) 30 Fe bal B 1 Cu 0.1 al 0.5 Zr 0.1 After adding lubricant and anti-oxidant to the magnetic powder and mixing them evenly, the magnetic powder is oriented and shaped under a 2T magnetic field under the protection of nitrogen, and is made into a green body by 200MPa cold isostatic pressing. Put the green body into a vacuum sintering furnace, sinter and hold at 1060°C for 4 hours; then temper at 900°C for 3 hours, then perform a low-temperature tempering treatment at 540°C for 2 hours, and perform a secondary low-temperature tempering at 500°C Processing 2h. The magnetic properties of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com