Melting device for plastic processing

A melting device and plastic technology, applied in the field of plastic processing, can solve problems affecting environmental quality, safety problems, high air pressure, etc., and achieve the effect of increasing the melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

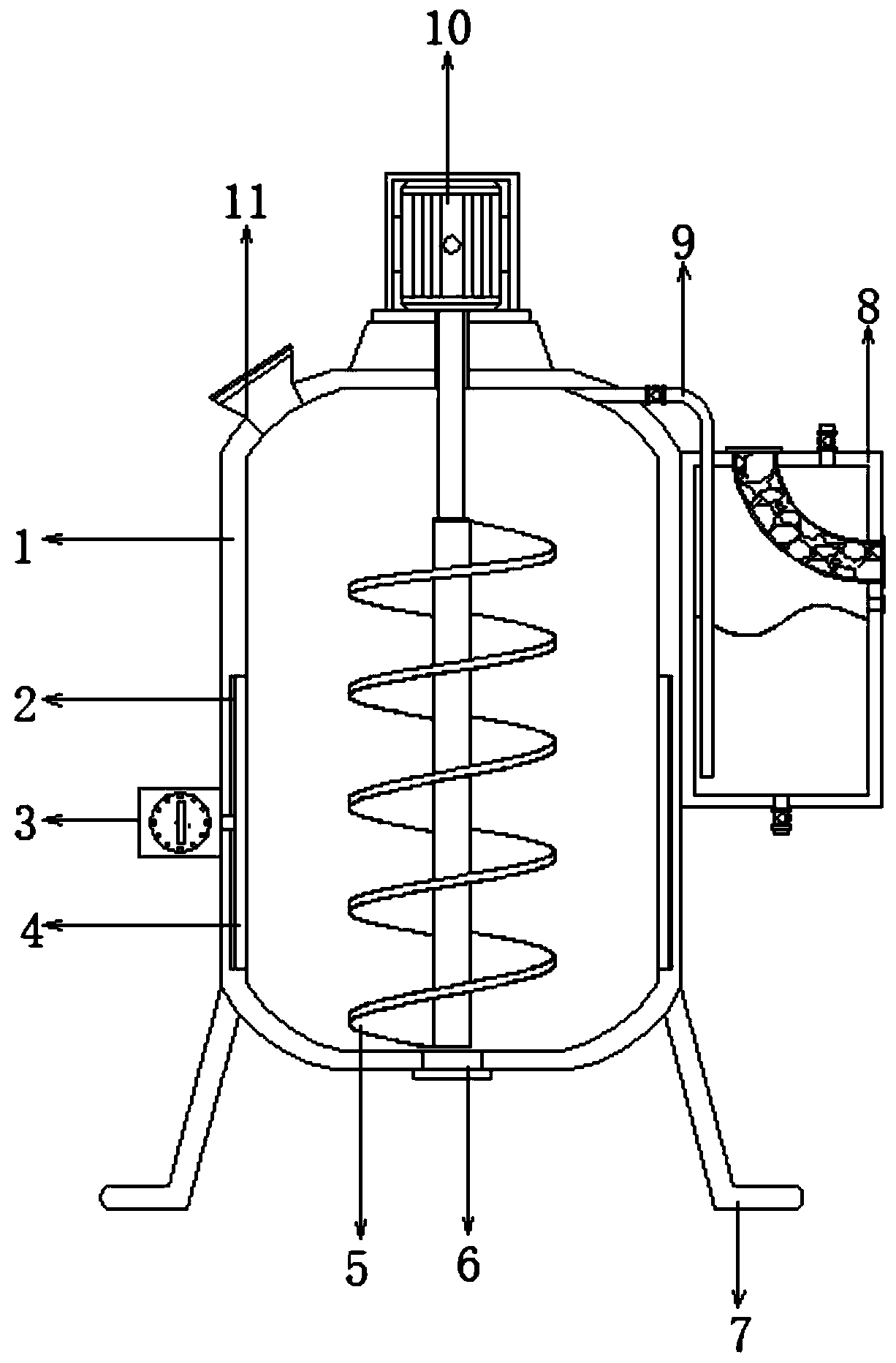

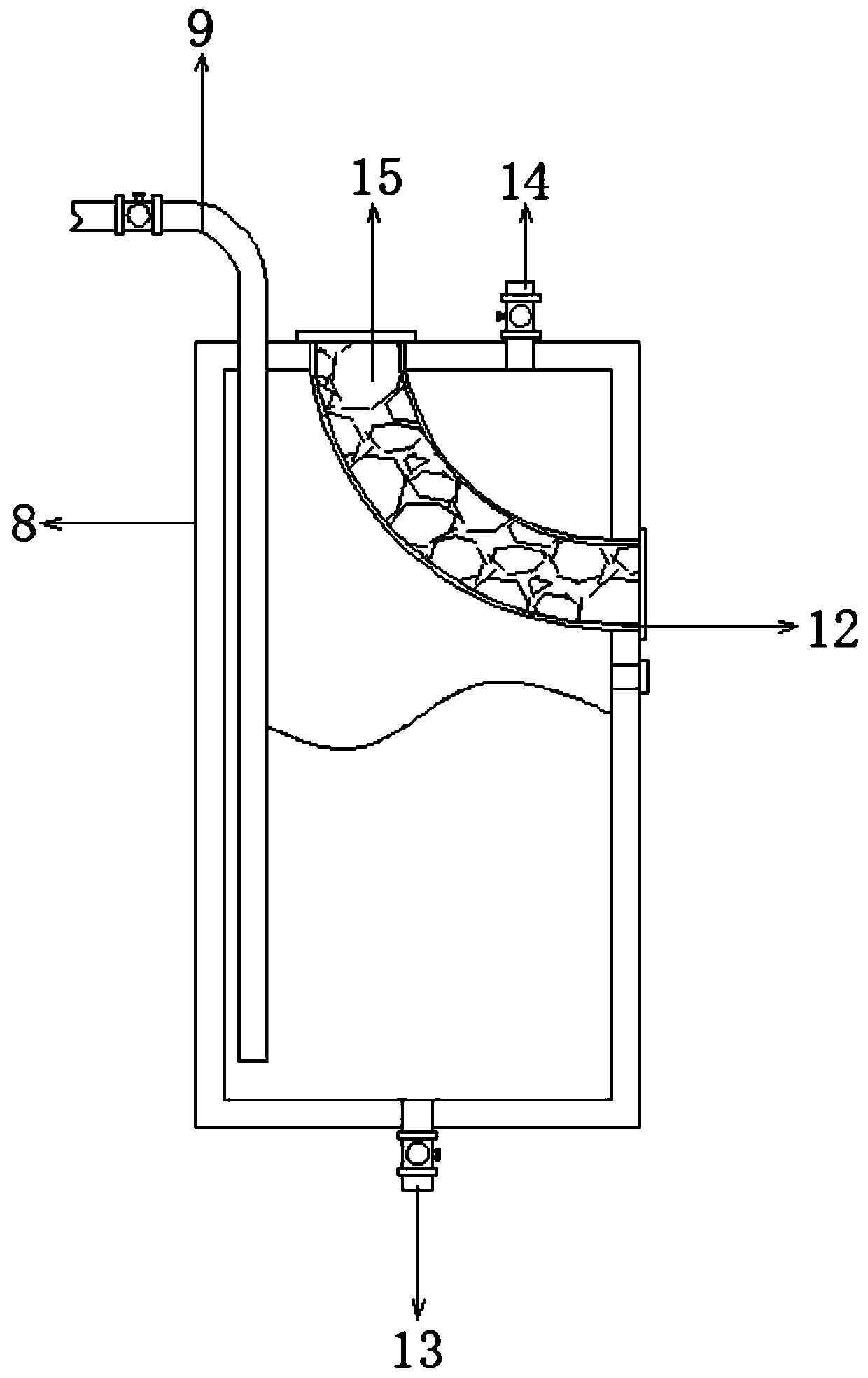

[0025] refer to Figure 1-2 , a melting device for plastic processing, comprising a melting tank 1, the top side of the melting tank 1 is connected with a feed hopper 11 by bolts, and the top of the feeding hopper 11 is provided with a first sealing cover, and the bottom of the melting tank 1 is opened There is a discharge port 6, and the inside of the discharge port 6 is provided with a second sealing cover, the bottom of one side of the outer wall of the melting tank 1 is connected with an electromagnetic heater 3 by bolts, and the inner bottom of the melting tank 1 is provided with an annular groove 2, One side of the electromagnetic heater 3 is connected with a heating tube inserted in the annular groove 2 by bolts, one end of the heating pipe is welded with an annular heating plate 4, and the top of one side of the melting tank 1 is connected with a liquid storage tank 8 by bolts, and The top side of the melting tank 1 is welded with an exhaust pipe 9 plugged into the liq...

Embodiment 2

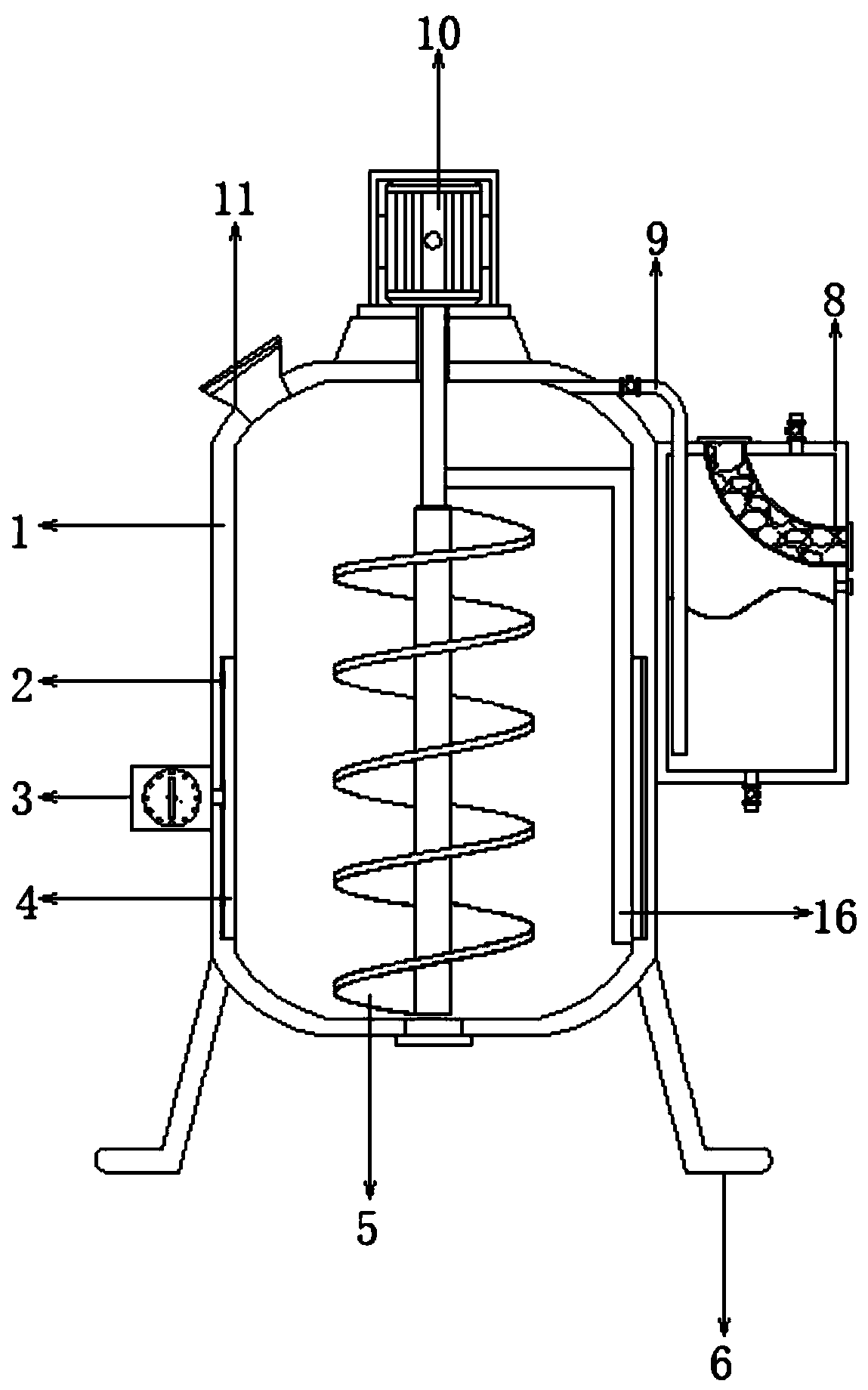

[0032] refer to image 3 , a melting device for plastic processing. Compared with Embodiment 1, this embodiment has a scraper 16 welded to the bottom of one side where the output shaft of the motor 10 extends into the melting tank 1, and the outer wall of one side of the scraper 16 is connected to the melting tank 1. The inner phases of tank 1 are in contact.

[0033] Working principle: When in use, the user uses the motor 10 to drive the scraper 16 to rotate inside the melting tank 1, and scrapes the plastic attached to the inside of the melting tank 1 through the scraper 16 to prevent the plastic from adhering to the inner wall of the tank And affect the output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com