Glass ceramic for blue light-excited white-light LED (Light-Emitting Diode), and preparation method thereof

A glass ceramic, blue light excitation technology, applied in the field of solid luminescent materials, can solve the problems of LED color shift, limited service life, easy yellowing of epoxy resin, etc., and achieves stable physical and chemical properties, adjustable color temperature, and high color rendering index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

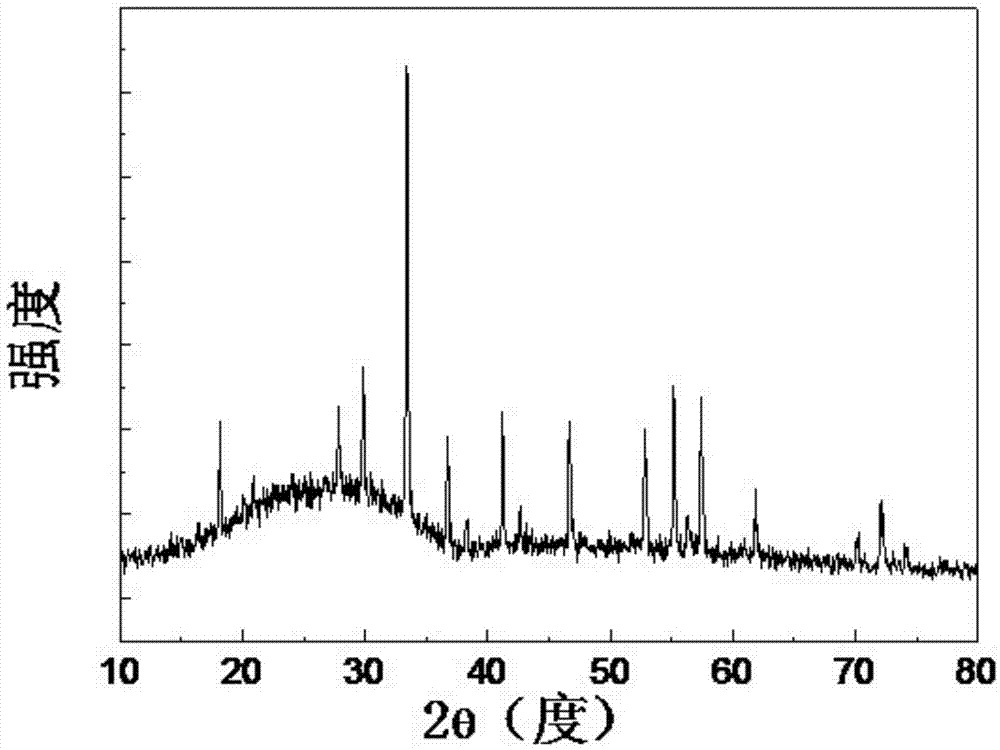

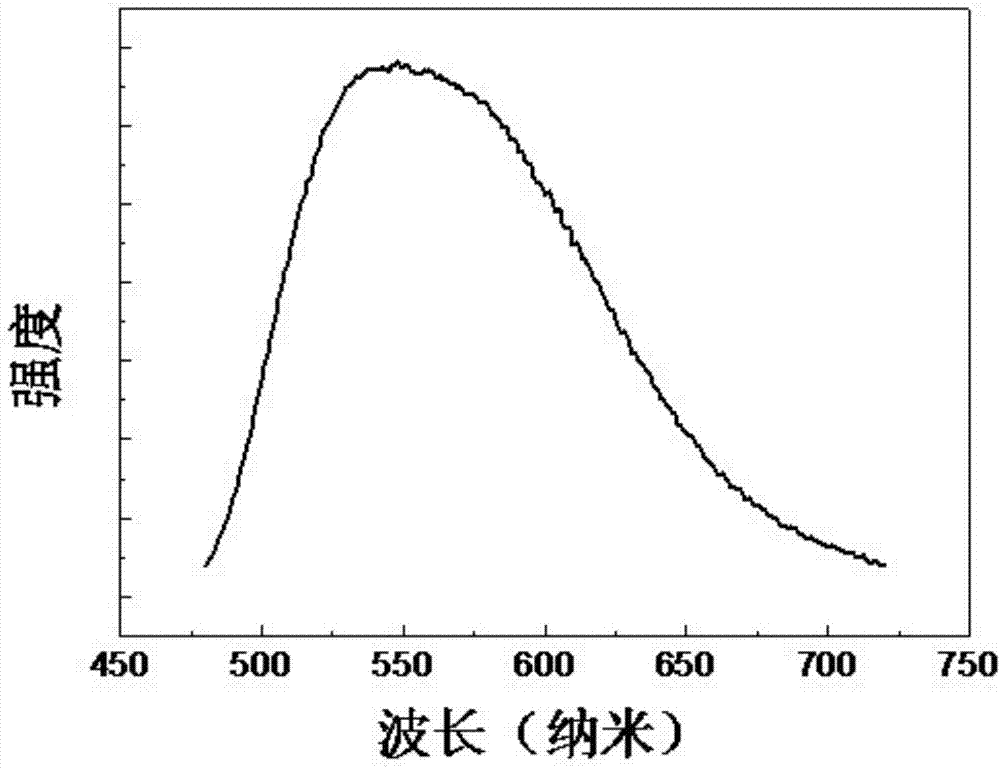

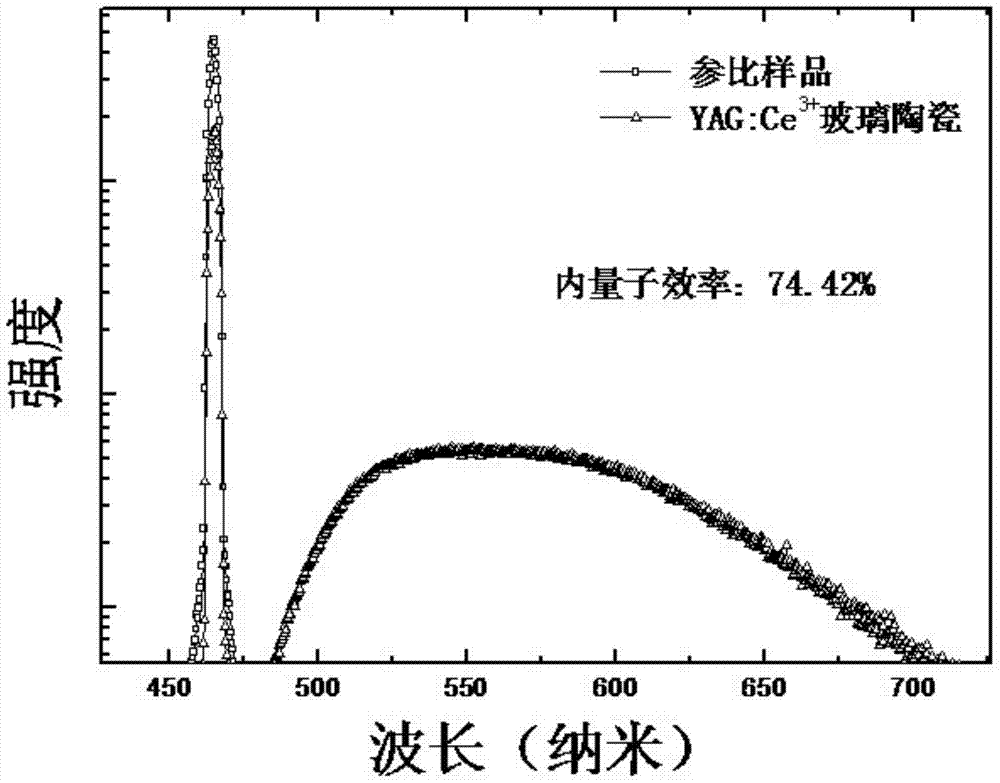

[0019] Example 1: Analytical pure SiO 2 , Y 2 o 3 、Al 2 o 3 , Li 2 CO 3 , ZrO 2 , CeO 2 Powder, according to 0.5CeO 2 : 15SiO 2 : 34.5Y 2 o 3 : 20Al 2 o 3 : 15Li 2 CO 3 : 15ZrO 2 (Molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1500°C in an atmosphere protection furnace, and kept for 1 hour, then, The molten liquid is quickly poured into a graphite mold to form a glass ceramic directly; the obtained glass ceramic is placed in a resistance furnace, annealed at 800°C for 3 hours, and then cooled with the furnace to eliminate internal stress. X-ray diffraction results (such as figure 1 shown) indicates that Y is precipitated in the glass matrix 3 Al 5 o 12 crystal phase. The sample was surface polished (sample thickness 0.5 mm), and its emission spectrum at room temperature was measured with a FLS920 fluorescence spectrometer (such as f...

example 2-18

[0020] Example 2-18: Change the material composition and process conditions of Example 1 (see Table 1, Table 2), and obtain glass ceramics directly after quenching the melt. X-ray diffraction results showed that Y was precipitated in the glass matrix 3 Al 5 o 12 crystal phase. The surface of the sample is polished (sample thickness is 0.5 mm), and its emission spectrum at room temperature is measured with a FLS920 fluorescence spectrometer. Under 465 nm blue light excitation, for Examples 2-12, Ce was detected 3+ : 5d→4f broadband emission (such as figure 2 shown); for Examples 13-14, Ce 3+ : The broadband emission of 5d → 4f appears red-shifted; for examples 15-18, Ce is also observed 3+ : 5d → 4f broadband emission and co-doped with different active ions (Eu 3+ ,Sm 3+ ,Pr 3+ ,Mn 2 ) of the red emission. The above-mentioned glass-ceramic samples all emit bright white light when observed with the naked eye.

[0021] Table 1 Material composition and process conditi...

example 19-24

[0025] Examples 19-24: Change the material components and process conditions of Example 1 (see Table 3), and obtain glass ceramics directly after quenching the melt. The results of X-ray diffraction showed that the precipitation of R in the glass matrix 3 m 5 o 12 (R=Y, one of Gd, Lu, Sc, La; M=Al, one of Ga, In) crystal phase. The surface of the sample is polished (sample thickness is 0.5 mm), and its emission spectrum at room temperature is measured with a FLS920 fluorescence spectrometer. Under the excitation of 465 nm blue light, the typical Ce can be observed 3+ : 5d → 4f broadband emission. The above-mentioned glass-ceramic samples all emit bright white light when observed with the naked eye.

[0026] Table 3 Material composition and process conditions

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com