Production process of edible braciola for pet

A production process and pet technology, applied in the field of pet edible meat roll production process, can solve problems such as affecting the appearance of pet food, affecting pet food sales, reducing food performance, etc., to achieve the effects of promoting sales, cleaning teeth, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

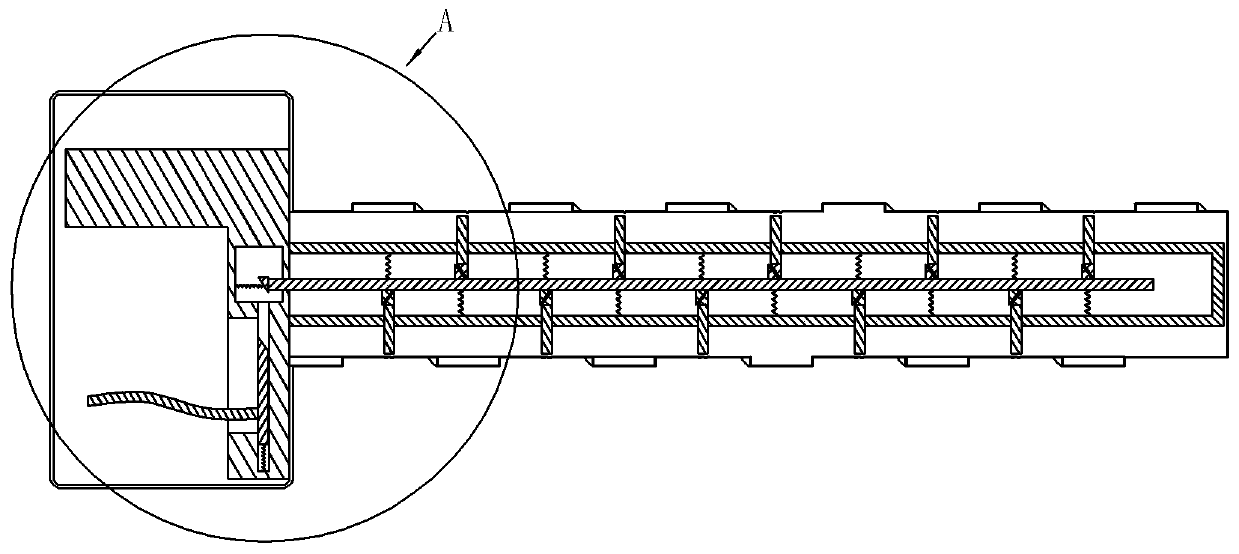

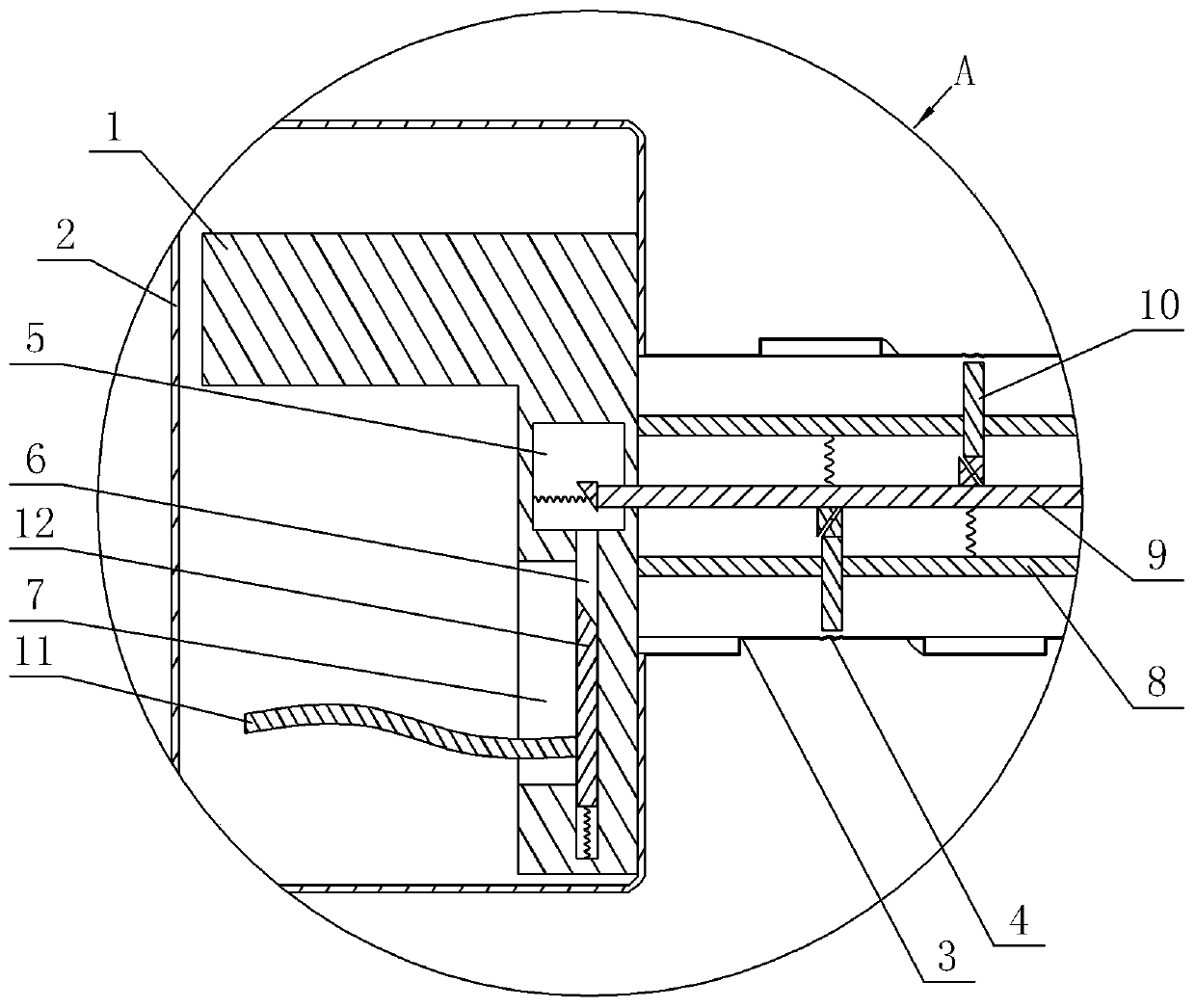

Image

Examples

Embodiment 1

[0034] The processing method of pet edible meat roll production technology comprises the following steps:

[0035] Step 1: Use an extruder to extrude starch, chicken puree and edible gelatin into strips and use a conveyor belt for constant speed transmission; the extruder adopts the ZC-75D twin-screw extruder produced by Nanjing Xinhui Machinery Co., Ltd. , The shape of the extruding mouth of extruder and starch layer 15 and chicken mash layer 16 is identical.

[0036] Step 2: Hole the starch and meat paste synchronously and equidistantly to obtain hollow holes; the punching equipment uses a cylinder, and the output shaft of the cylinder is welded with a perforating tube, which is connected to the negative pressure fan, and the perforating tube is inserted into the After the starch and meat paste are sucked away by negative pressure, the starch and meat paste in the punching tube are sucked away to form hollow holes.

[0037] Step 3: The starch, chicken puree and edible gelat...

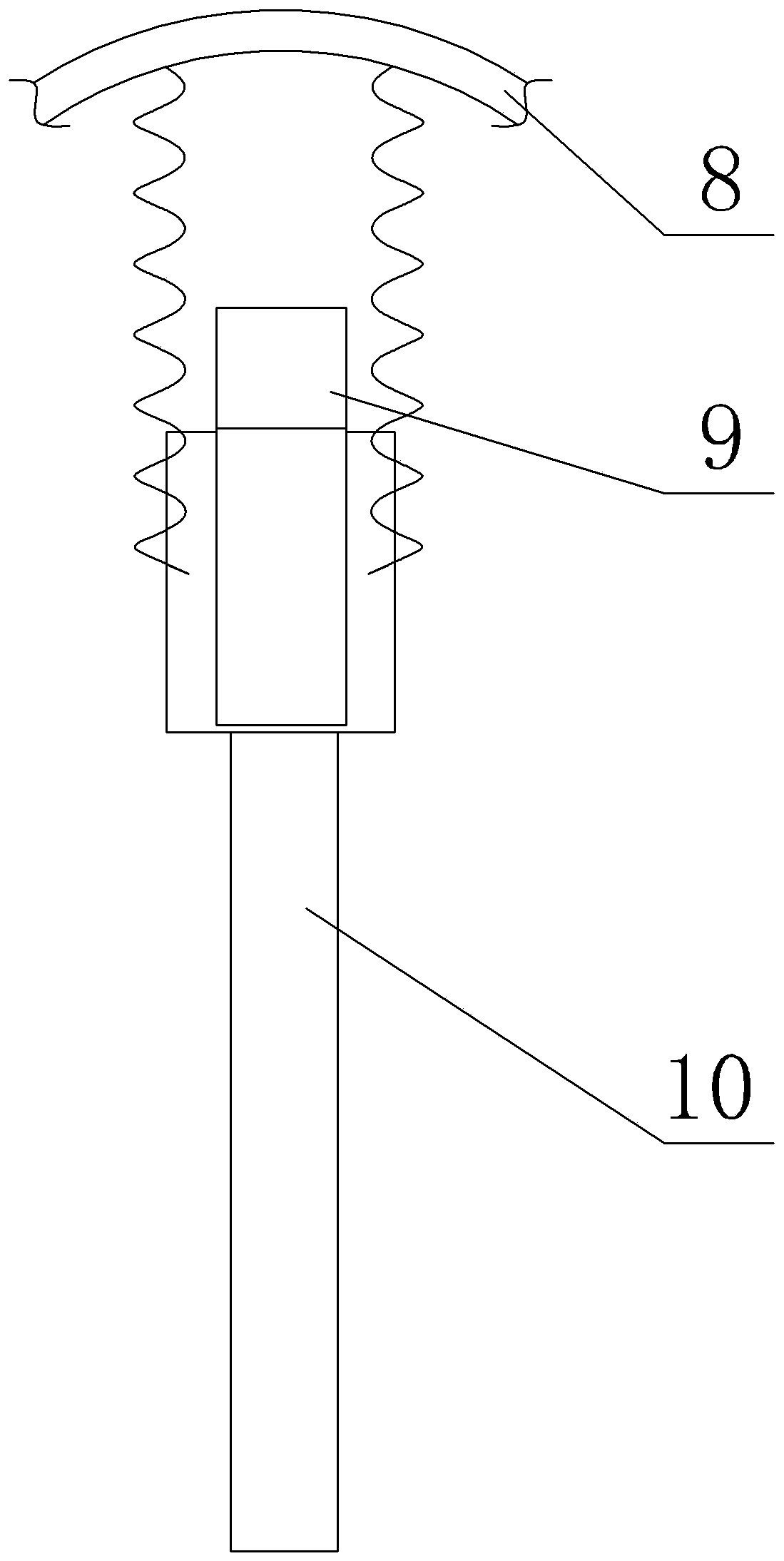

Embodiment 2

[0049] Different from Example 1, as image 3 As shown, the wedge block welded to the upper end of the entire raised bar 10 is connected to the inner side wall of the entire convex tube 8 through two extension springs, and the wedge block welded to the side wall of the sliding bar 9 and the sliding bar 9 can pass between the two extension springs. . figure 2 The wedge block welded with the left end of the slide bar 9 is also connected with the left side wall of the cavity 5 by two extension springs, and the push bar 12 can pass between the two extension springs. In addition, the thickness of the natural latex rubber forming the screw portion 3 was 0.04 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com