Foam double-sided adhesive tape and production method thereof

A technology of double-sided tape and foam, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problem of limited application, adhesive performance, ring test resistance, cushioning performance, and shear resistance Performance Light-shielding performance, easy to remove problems such as heavy industry, to achieve the effect of easy operation, high-level bonding force, suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

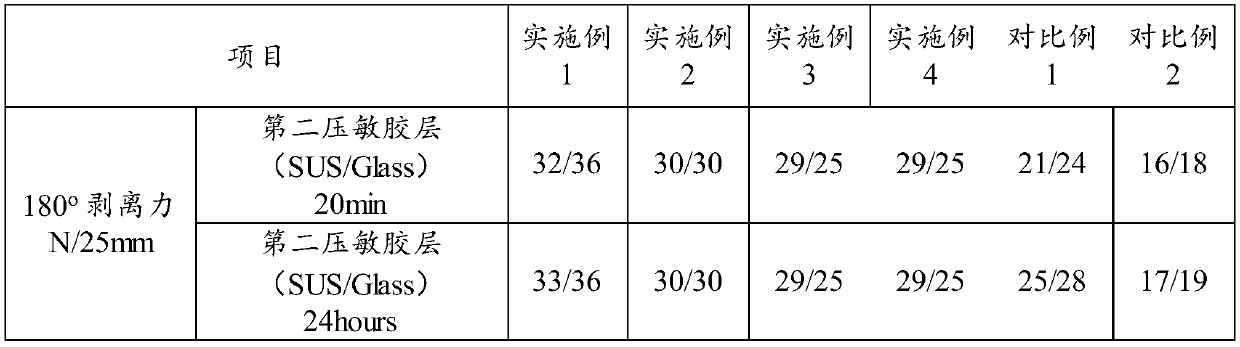

Examples

preparation example Construction

[0089] The present invention also provides a method for preparing the foam double-sided adhesive tape described in the above technical solution, comprising the following steps:

[0090] a) Mix the thermoplastic elastomer and the reinforcing agent in the solvent evenly, then add the tackifying resin, softener, antioxidant and filler in sequence for mixing to obtain the adhesive dispersion; then apply the above adhesive dispersion to the release material Dry on the surface to obtain a removable pressure-sensitive adhesive layer compounded with a release material on one side;

[0091] b) Attach the first pressure-sensitive adhesive layer compounded with a release material on one side of the foam layer, and then attach the second pressure-sensitive adhesive layer compounded with a release material on the other side of the foam layer , after removing the release material on the second adhesive pressure-sensitive adhesive layer, it is rolled up to obtain a foam double-sided adhesive...

Embodiment 1

[0120] The foam double-sided adhesive tape provided by embodiment 1 is based on PU black foam with a total thickness of 600 μm (comprising an ultra-thin PET layer with a thickness of 10 μm compounded on one side); A removable rubber pressure-sensitive adhesive layer with a thickness of 200 μm is attached; one side of the ultra-thin PET layer of the substrate is coated with an acrylic pressure-sensitive adhesive layer with a thickness of 50 μm; the other side of the acrylic pressure-sensitive adhesive layer is compounded with Double silicon glassine release material with a thickness of 110μm.

[0121] The removable rubber pressure-sensitive adhesive layer is prepared from the raw materials of the following components: 55 parts by weight of styrene-isoprene-styrene block copolymer (SIS), 45 parts by weight of terpene resin, poly 15 parts by weight of styrene, 20 parts by weight of naphthenic oil, 0.5 parts by weight of bulky hindered phenolic antioxidant, and 2 parts by weight o...

Embodiment 2

[0134] The foam double-sided adhesive tape provided by embodiment 2 is based on PU black foam (comprising an ultra-thin PET layer with a thickness of 10 μm compounded on one side) with a total thickness of 600 μm; A removable rubber pressure-sensitive adhesive layer with a thickness of 200 μm is attached; one side of the ultra-thin PET layer of the substrate is coated with an acrylic pressure-sensitive adhesive layer with a thickness of 50 μm; the other side of the acrylic pressure-sensitive adhesive layer is compounded with Double silicon glassine release material with a thickness of 110μm.

[0135] The removable rubber pressure-sensitive adhesive layer is prepared from the raw materials of the following components: 50 parts by weight of styrene-ethylene / propylene-styrene block copolymer (SEPS), 45 parts by weight of terpene resin, polystyrene 15 parts by weight of ether, 20 parts by weight of naphthenic oil, 1 part by weight of bulky hindered phenolic antioxidant, and 2 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com