Ternary lithium ion battery and preparation method thereof

A lithium-ion battery and battery technology, applied in the field of lithium-ion batteries, can solve the problems of non-controllability, poor cycle performance, unavoidable side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

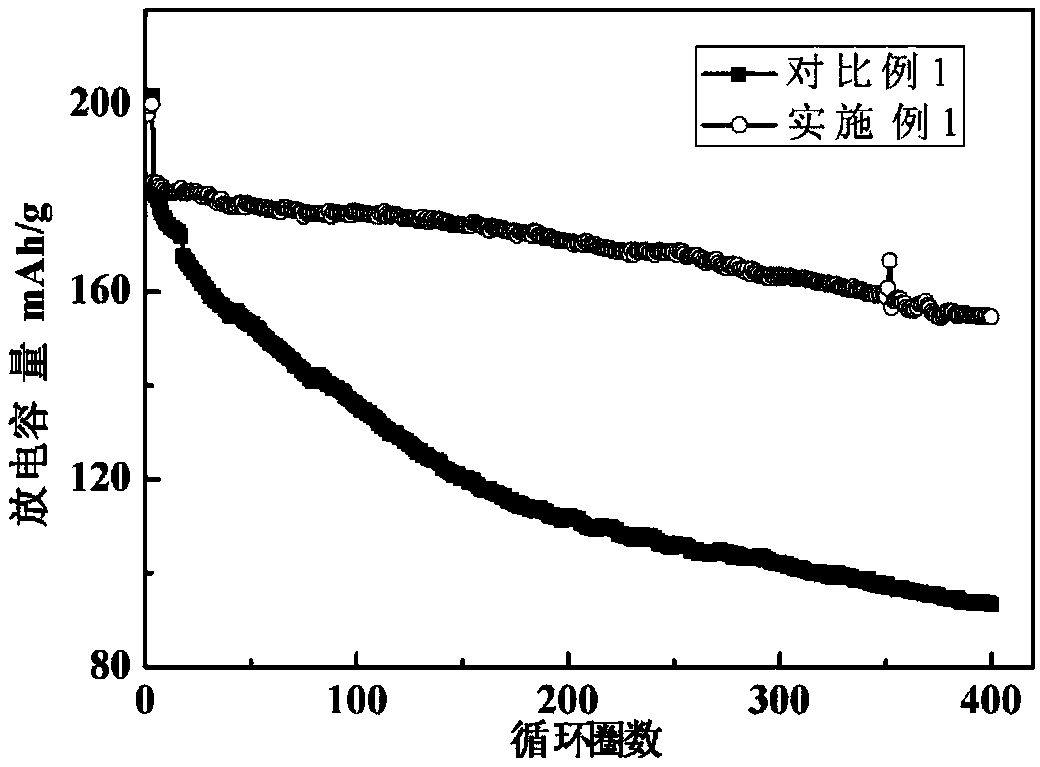

Embodiment 1

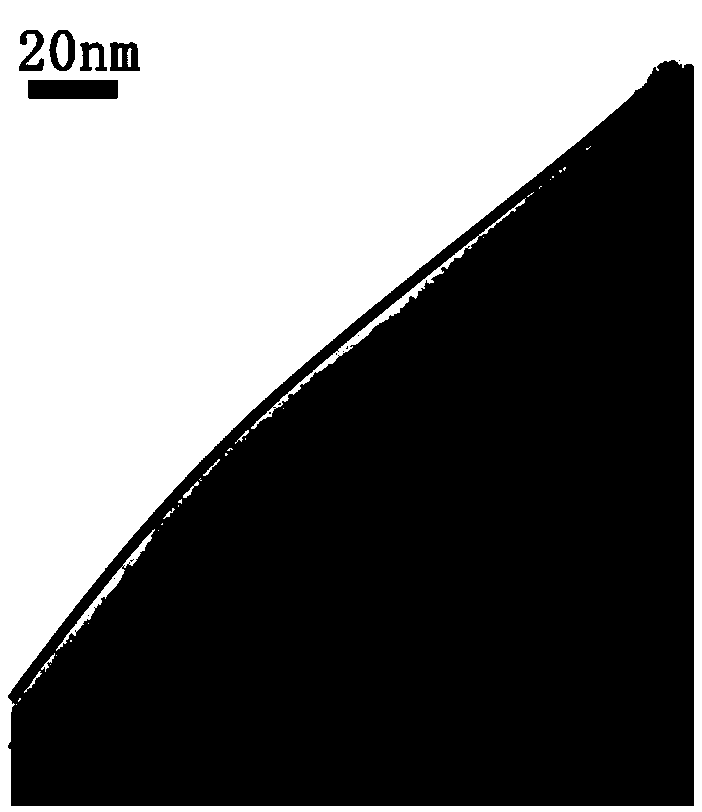

[0069] (1) Configure cyclic carbonate (EC) and linear carbonate diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) in a mass ratio of 1:1:1, add 1 mol / L lithium salt lithium hexafluorophosphate, add Film-forming additive triisopropyl borate (addition is 1wt%), obtains the electrolytic solution containing film-forming additive;

[0070] (2) Add the electrolyte described in (1) into the ternary NCM622 half-cell to assemble the battery (use the existing assembly method to assemble into a half-cell, the assembly sequence is, for example: positive electrode case, positive electrode sheet (including positive electrode material and Positive electrode current collector), electrolyte diaphragm, electrolyte, lithium sheet, negative electrode current collector, the assembly process is carried out in a glove box, and the diaphragm is a polypropylene diaphragm;

[0071] (3) Put the battery in the blue electric test system, set the current density to 0.1C, cycle 5 times, take out the ...

Embodiment 2

[0074] (1) Configure cyclic carbonate (EC) and linear carbonate diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) in a mass ratio of 1:1:1, add 1 mol / L lithium salt lithium hexafluorophosphate, add Film-forming additive triisopropyl phosphite (addition is 1wt%), obtains the electrolytic solution containing film-forming additive;

[0075] (2) Add the electrolyte described in (1) into the ternary NCM523 half-cell to assemble the battery (refer to Example 1 for the assembly method);

[0076] (3) Put the battery in the blue electric test system, set the current density to 0.1C, cycle 5 times, take out the positive electrode after the cycle, and complete the pretreatment in the glove box;

[0077] (4) Assemble the battery with the positive electrode sheet obtained in step (3), and use cyclic carbonate (EC) and linear carbonate diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) (1:1:1, mass ratio ), the concentration of the lithium salt lithium hexafluorophosphate is 1...

Embodiment 3

[0079] (1) Configure cyclic carbonate (EC) and linear carbonate diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) in a mass ratio of 1:1:1, add 1mol / L lithium salt lithium hexafluorophosphate, and add Membrane additive triisopropyl phosphite and triisopropyl borate (mass ratio is 1: 1, total addition is 1wt%), obtains the electrolytic solution containing film-forming additive;

[0080] (2) Add the electrolyte described in (1) into the ternary NCM622 half-cell to assemble the battery (refer to Example 1 for the assembly method);

[0081] (3) Put the battery in the blue electric test system, set the current density to 0.1C, cycle 5 times, take out the positive electrode after the cycle, and complete the pretreatment in the glove box;

[0082] (4) Assemble the battery with the positive electrode sheet obtained in step (3), and use cyclic carbonate (EC) and linear carbonate diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) (1:1:1, mass ratio ), the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com