Nitrogen-doped expanded graphite paper current collector and preparation and application thereof

A technology of expanded graphite and nitrogen doping, which is applied in the direction of electrode carrier/current collector, non-aqueous electrolyte battery electrode, electrochemical generator, etc., which can solve the problems of poor composite effect with active materials and easy falling off, so as to improve the rate performance , simple preparation process, high nitrogen doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The nitrogen-doped expanded graphite paper current collector of this embodiment is prepared through the following steps: the ionic liquid 1-ethyl-3-methylimidazolium dicyandiamide salt ([Emim][dca]) (Money Chemical Technology ( Shanghai) Co., Ltd.) was diluted in ethanol solvent to 5% by volume, and the graphite paper with a thickness of 0.02mm was soaked in the diluted ionic liquid solution of 5% by volume for 30min, and then heated in an air atmosphere at 10°C / Raise the temperature of the muffle furnace to 500°C at a heating rate of 1 min, transfer the graphite paper soaked with the ionic liquid into the muffle furnace, and take it out after holding for 10 min to obtain a nitrogen-doped expanded graphite paper current collector with a thickness of 0.2 mm.

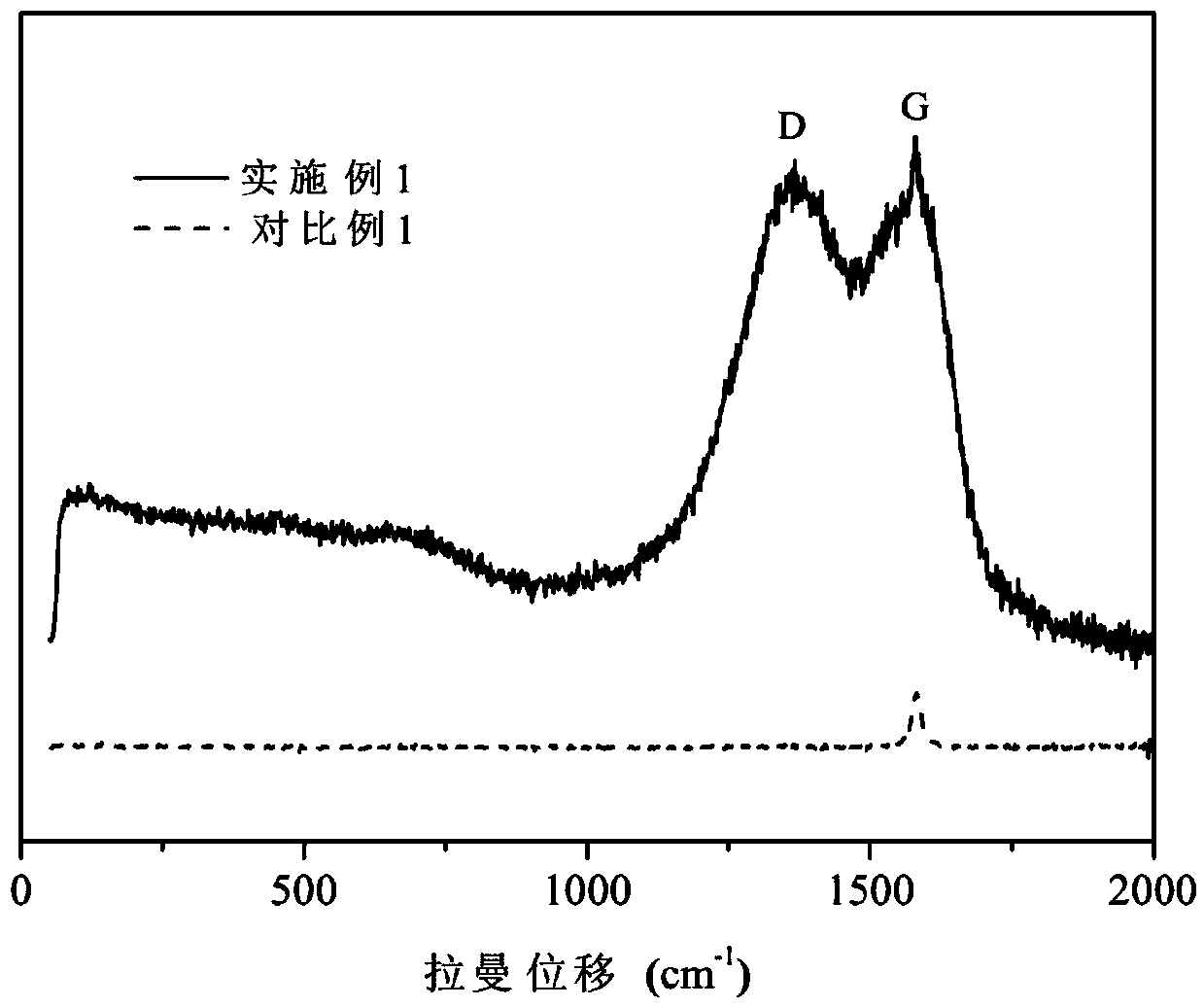

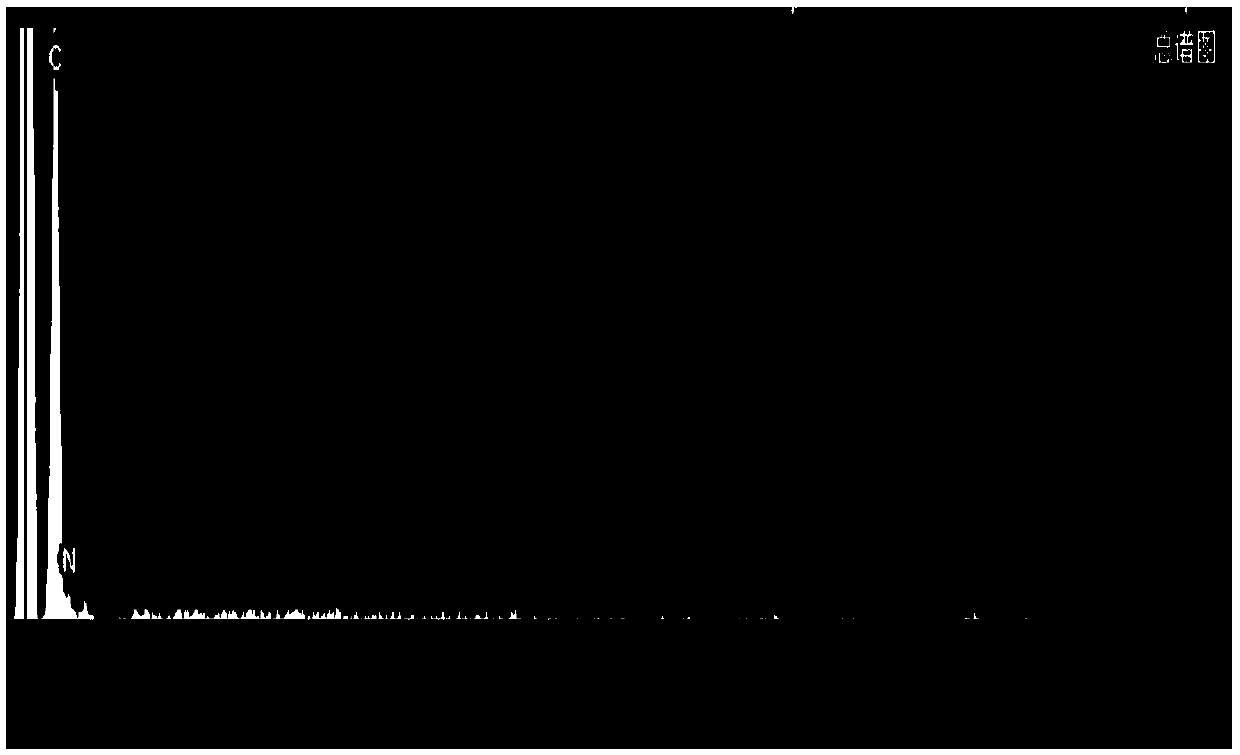

[0058] Raman spectroscopy is used to detect the nitrogen-doped expanded graphite paper current collector obtained in this embodiment, and the results are as follows figure 1 As can be seen from the figure, the ni...

Embodiment 2

[0063] The nitrogen-doped expanded graphite paper current collector of this embodiment is prepared through the following steps: the ionic liquid 1-ethyl-3-methylimidazolium dicyandiamide salt ([Emim][dca]) (Money Chemical Technology ( Shanghai) Co., Ltd.) was diluted to 10% by volume in ethanol solvent, soaked graphite paper with a thickness of 0.02mm in the diluted ionic liquid solution of 10% by volume for 30min, and then heated in an air atmosphere at 10°C / Raise the temperature of the muffle furnace to 500°C at a heating rate of min, transfer the graphite paper soaked in the ionic liquid into the muffle furnace, and take it out after holding for 10 minutes to obtain a nitrogen-doped expanded graphite paper current collector with a thickness of 0.5 mm. The nitrogen doping concentration was 25 at.%.

[0064] Adopt scanning electron microscope to observe the nitrogen-doped expanded graphite paper current collector that present embodiment obtains, and photo is as image 3 As ...

Embodiment 3

[0066] In this embodiment, the nitrogen-doped expanded graphite paper obtained in Example 2 is used as the current collector of elemental sulfur to prepare the lithium-sulfur battery positive electrode. Mix 70wt% elemental sulfur, 20wt% conductive agent acetylene black, and 10wt% binder polyvinylidene fluoride, and use N-methylpyrrolidone as a solvent, stir evenly to obtain positive electrode slurry, use a coating machine to coat, vacuum Dry in a drying oven at 60° C. to obtain a positive electrode sheet.

[0067] The nitrogen-doped expanded graphite paper current collector pole sheet of the negative electrode obtained by the present embodiment having a sulfur active material is observed with a scanning electron microscope, and the results are as follows Figure 4 As shown, it can be seen that after the current collector obtained in this example is loaded with active materials, the surface is flat and loose and porous, which is conducive to the infiltration of the electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com