Cationic dye ink composition for digital inkjet and method for manufacturing printed textiles

A cationic dye and digital inkjet technology, applied in textiles and papermaking, dyeing, biochemical fiber treatment, etc., can solve ink storage stability, color concentration, poor washing fastness and light fastness, damage to metal parts, failure Achieve the effects of superior hand feel, bright colors, and mild post-processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059]

[0060] First, the components in the ink composition are uniformly mixed to obtain a dye solution. It should be noted that the order of adding the various ingredients is not particularly limited as long as they can be mixed uniformly. Next, the dye solution was filtered through a 5 μm polypropylene filter material, and then filtered through a 1 μm polypropylene filter material. After filtration, the dye solution was filtered through a 0.45 μm polyvinylidene fluoride membrane to prepare an ink composition.

[0061]

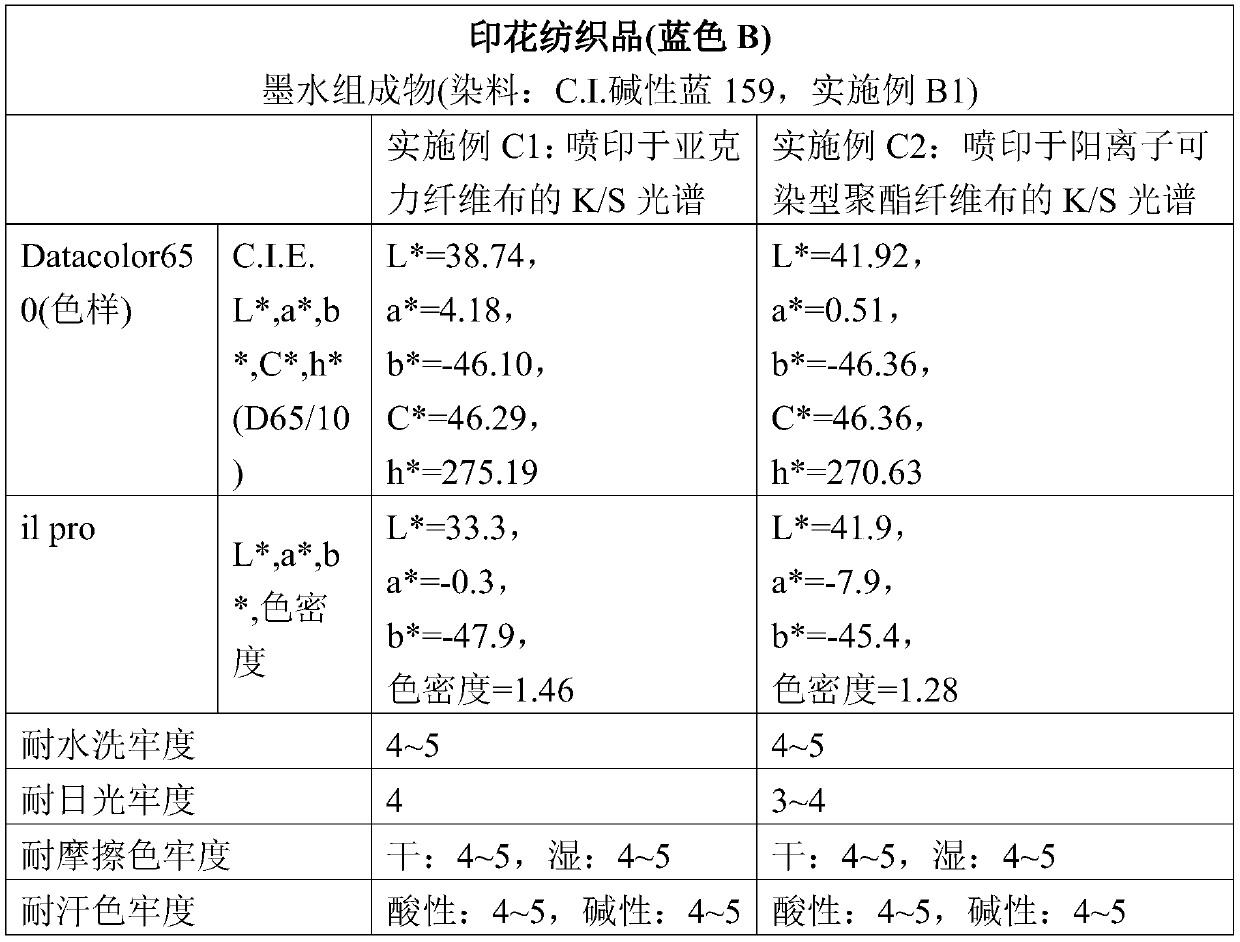

[0062] Specifically, the manufacturing method of printed textiles sequentially includes (i) sizing treatment, (ii) spray printing treatment and (iii) post-treatment. The steps are detailed below:

[0063] Step (i) Sizing treatment

[0064] The textile is subjected to sizing treatment to form a size layer on the textile, wherein the size layer is formed by a size composition.

[0065] There are no special restrictions on the sizing treatment method, p...

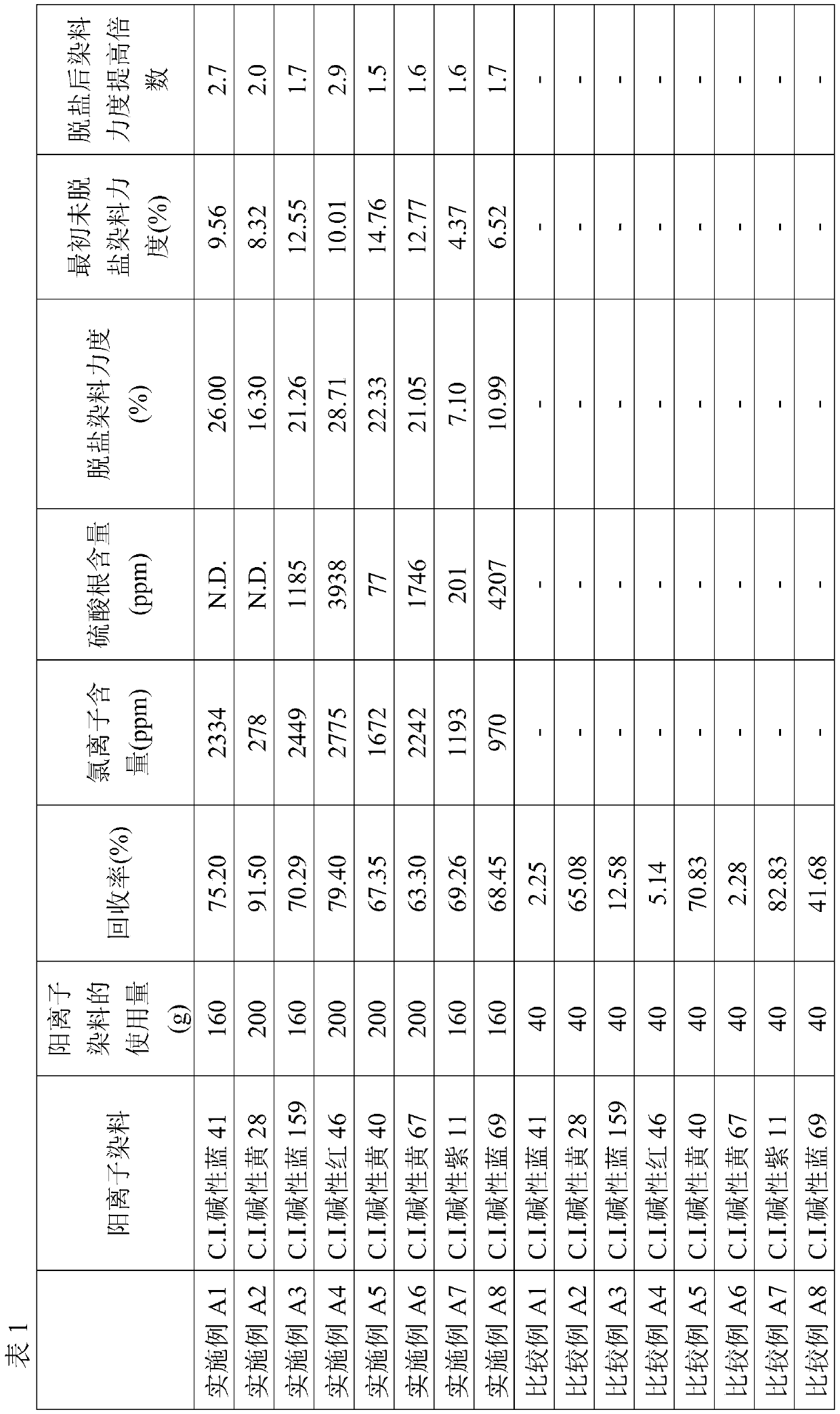

Embodiment A1 to Embodiment A8

[0079] Embodiment A1 to embodiment A8 (RO method)

[0080] Weigh 160-200 grams of filter cake or raw powder of self-made or commercially available high-concentration cationic dyes (as shown in Table 1 below). Add the filter cake or raw powder of high-concentration cationic dye to 8 liters of pure water to prepare a dye solution with a solid content of 2% to 2.5% by weight, adjust the pH of the dye solution to 7.0±0.2 with 3N NaOH and 3N HCl solution, and stir Heating under low temperature raised the temperature to 85° C., stirred at the temperature for 1 hour, stopped stirring and naturally cooled down to room temperature. The dye solution was filtered through a 5 μm polypropylene filter, and then filtered through a 1 μm polypropylene filter. After filtration, the dye solution is circulated and dialyzed against inorganic salts with a nanofiltration membrane, in which the nanofiltration membrane is made of polyamide, the surface of the membrane is negatively charged, the desal...

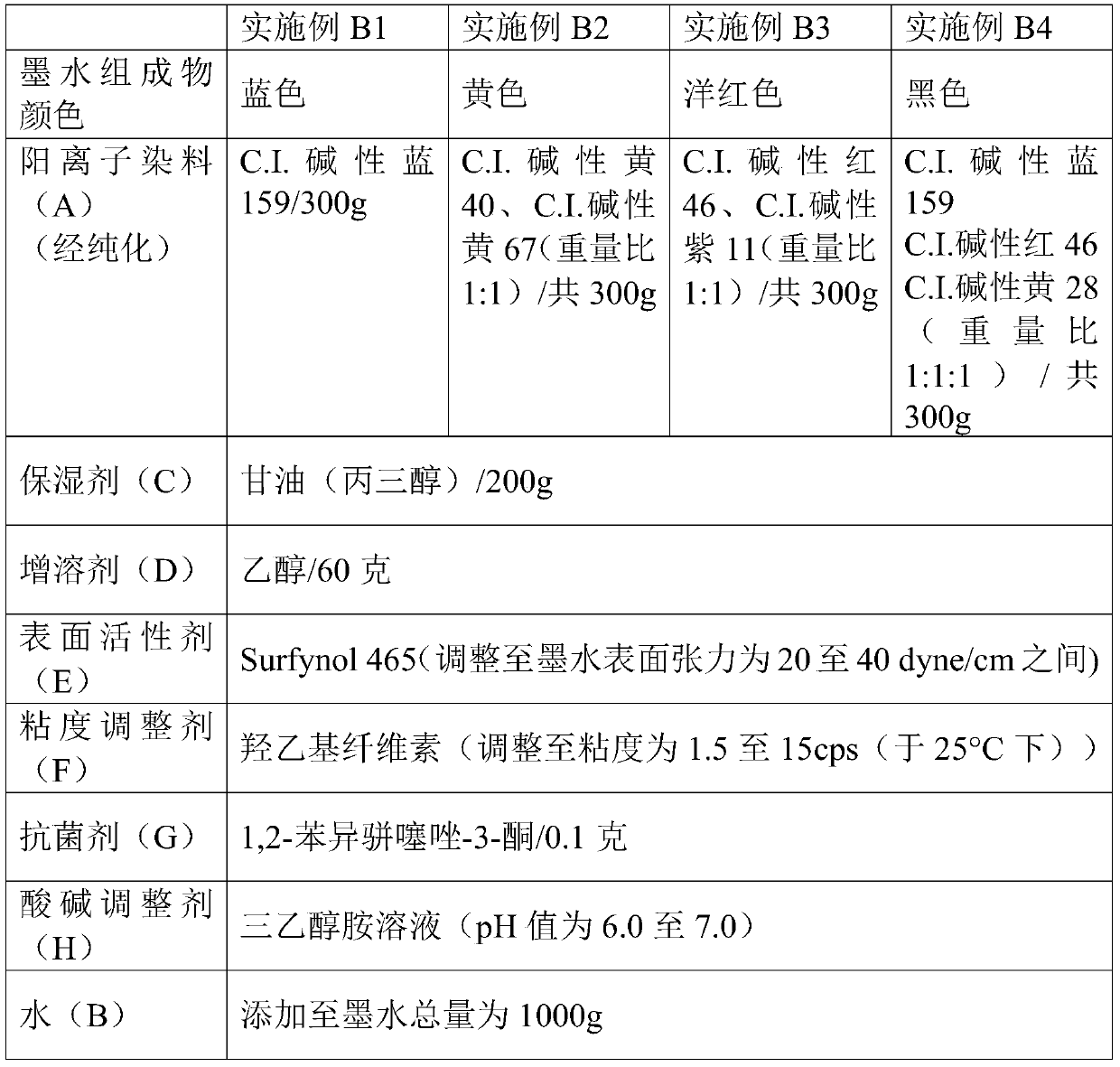

Embodiment B1

[0088] After 300 grams of cationic dye color paste (i.e. the prepared cationic dye color paste by embodiment A3) of C.I. basic blue 159 as cationic dye, 200 grams of glycerol (glycerol), and 60 grams of ethanol were stirred evenly, add 1 % by weight of hydroxyethyl cellulose, and an appropriate amount to adjust the viscosity of the ink at 25° C. to 1.5 to 15 cps. Next, add an appropriate amount of Surfynol 465 to adjust the surface tension of the ink to between 20 and 40 dyne / cm, add 0.1 g of antibacterial agent, and add an appropriate amount of triethanolamine to adjust the pH of the ink to 6.0 to 7.0, and use pure water to make up the total amount of the ink to 1000 grams, thereby preparing a blue dye solution. Filter the above dye solution with a 5 μm polypropylene filter material, then filter it with a 1 μm polypropylene filter material, and then filter the dye solution with a 0.45 μm polyvinylidene fluoride membrane to prepare the blue ink composition of Example B1 thing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com