A kind of preparation method and preparation device of water-based workshop precoat primer

A technology for pre-coating primers and preparation devices, which is applied in the direction of feeding devices, chemical instruments and methods, mixers with rotating stirring devices, etc., and can solve problems such as easy foaming, becoming waste, and poor performance of primers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

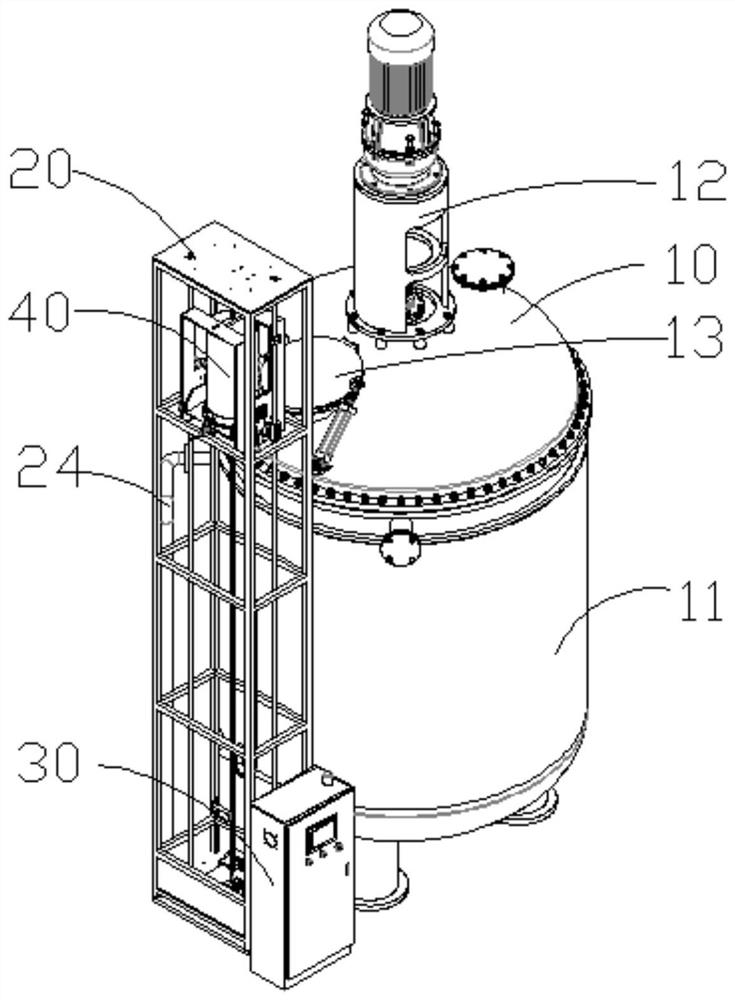

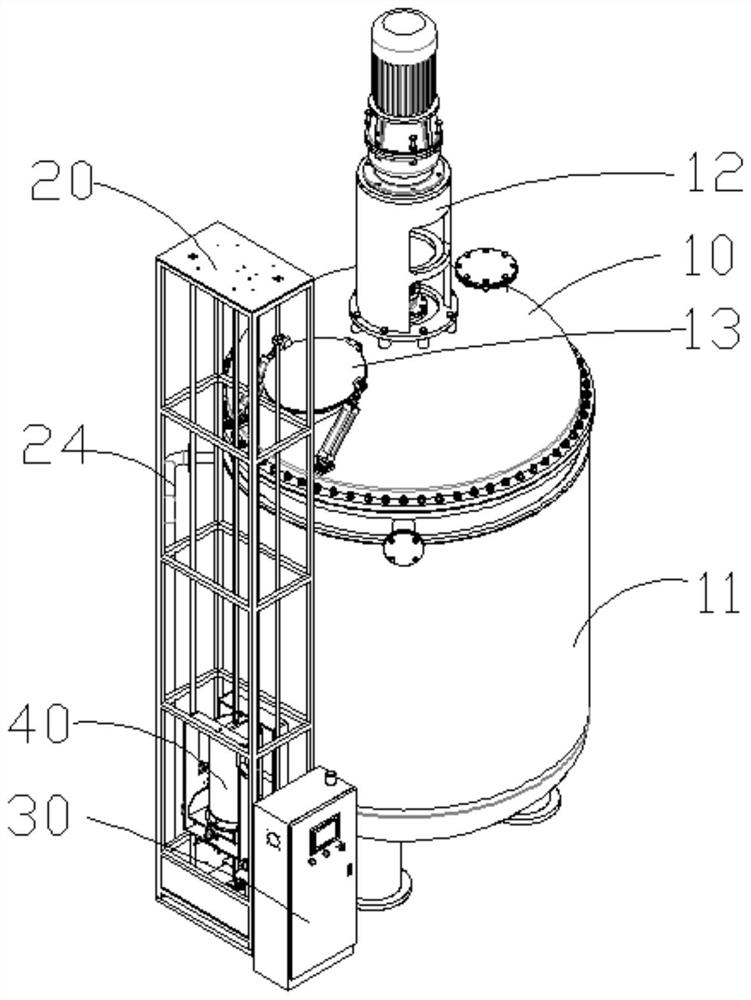

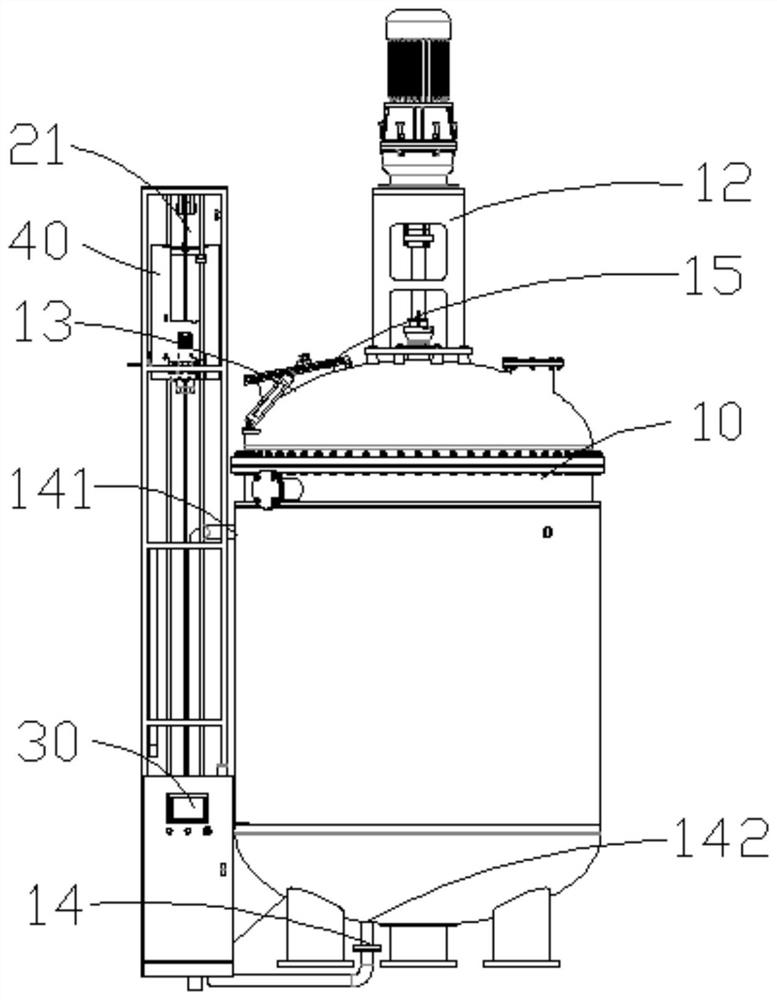

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] One embodiment of the present invention provides a kind of preparation method of water-based shop precoat primer and preparation device thereof, comprises the following steps:

[0047] S1. The raw materials for pre-coating primer include 30-40 parts of inorganic hybrid resin, 40-50 parts of 800-mesh zinc powder, 5-8 parts of zinc phosphate, 2-5 parts of nanomaterials, 0.5-1.5 parts of anti-flash rust agent, 0.5-1 part of dispersant, and the raw materials of the above-mentioned components are respectively contained in the corresponding raw material barrels 40; for example, in one embodiment of the present invention, 40 parts of inorganic hybrid resin, 48 parts of 800 mesh zinc powder, 7 parts of zinc, 3.2 parts of nanomaterials, 1 part of anti-flash rust agent, 0.8 part of dispersant; another example in another embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com