Biodegradable film extruder

A technology of biodegradable film and extruder, applied in the field of degradable film extruder, can solve the problems of poor heat preservation effect, achieve the effects of improving heat preservation effect, saving energy, and reducing heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

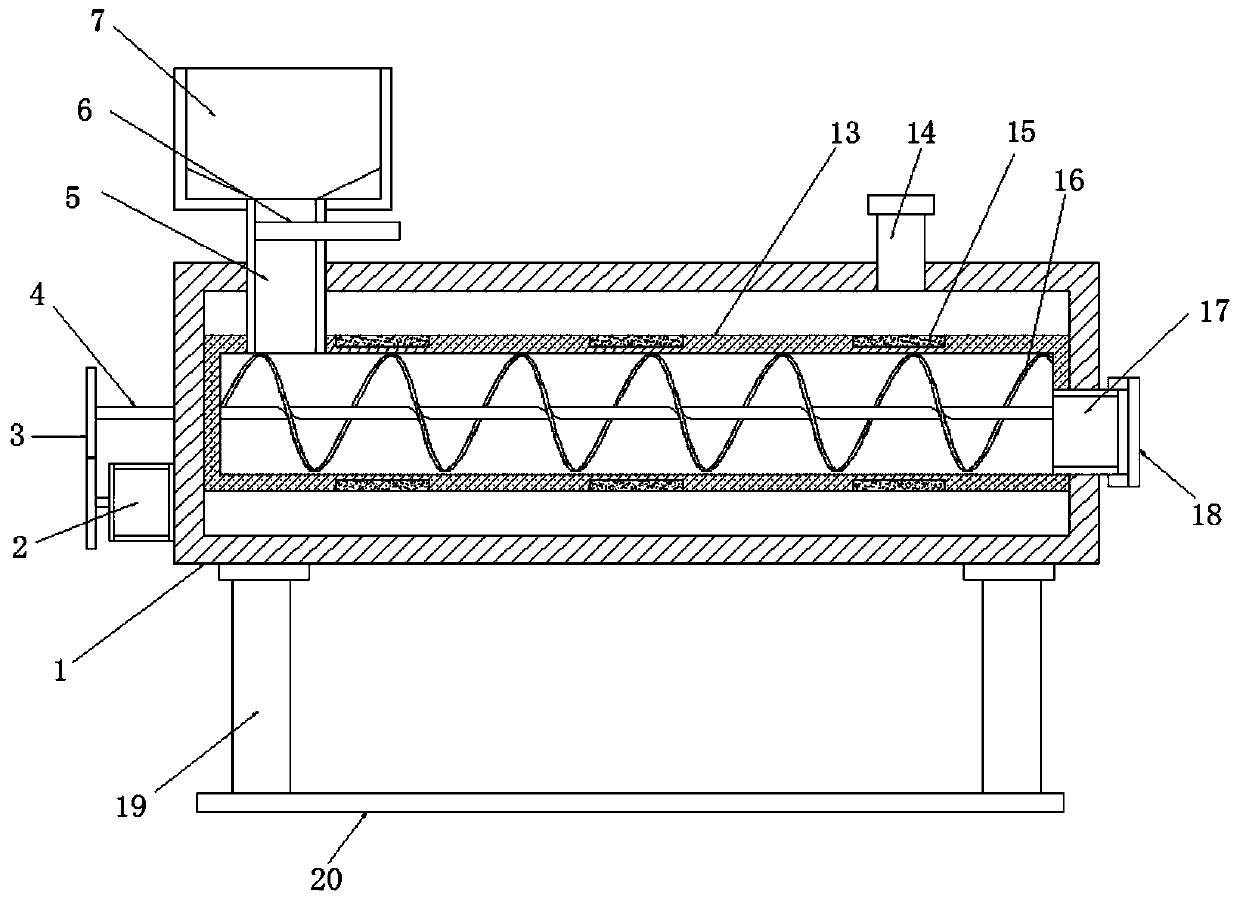

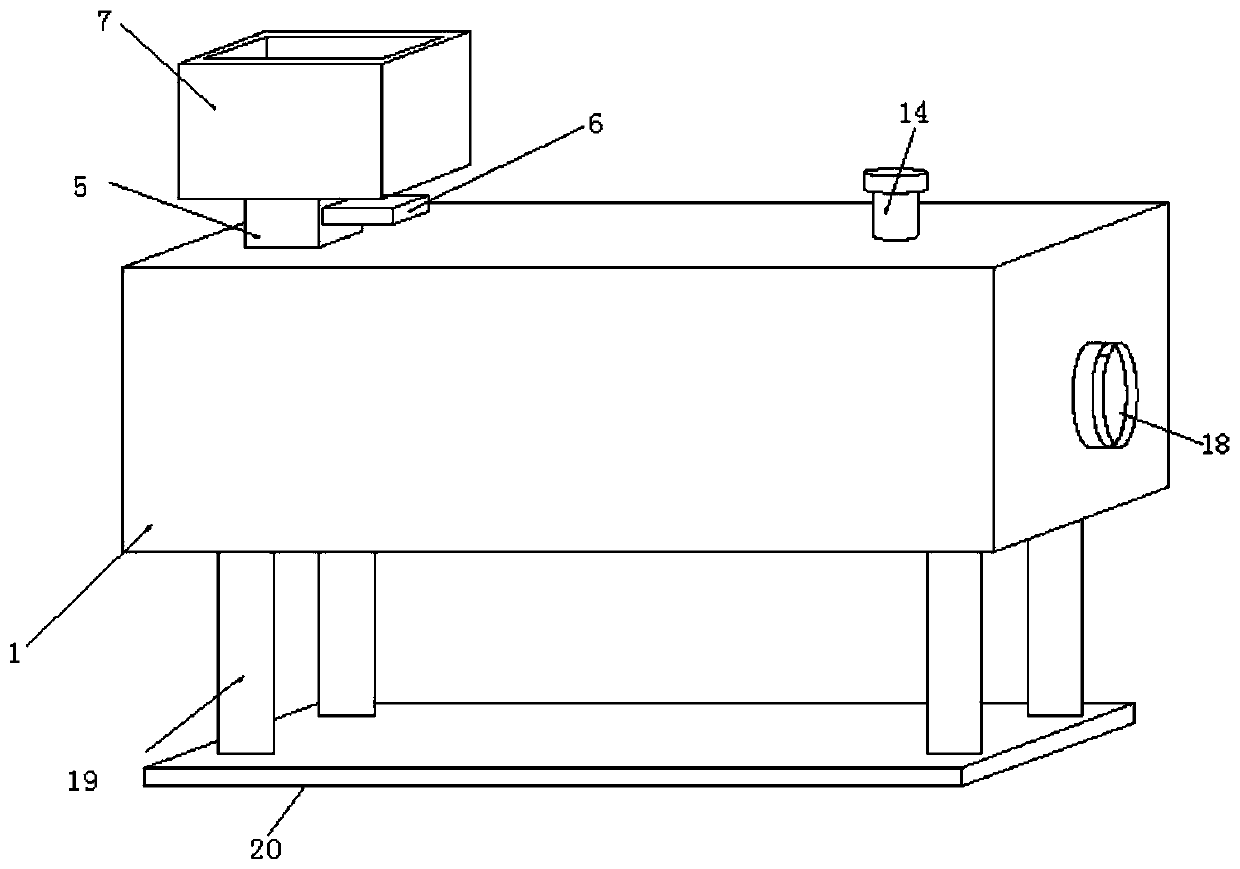

[0023] refer to figure 1 and figure 2 , a biodegradable film extruder, comprising an incubator 1, a heating box 13 is fixed in the incubating box 1, a rotating shaft 4 is inserted and rotated in the heating box 13, and a spiral blade is fixed at one end of the rotating shaft 4 located in the heating box 13 16. The other end of the rotating shaft 4 is fixed with a transmission gear 3, and the transmission gear 3 is connected with a driving mechanism. A plurality of equidistant heating plates 15 are fixed in the interlayer of the heating box 13, and the heating plate 15 between the heating box 13 and the incubator 1 The gap is filled with a heat exchange solution, and the heating box 13 can be fixed in the incubator 1 to achieve a heat preservation effect. The filled heat exchange solution can reduce the heat transfer rate and improve the heat preservation effect of the device. The top outer wall of the incubator 1 is fixed and plugged There is an exhaust pipe 14, a pressure r...

Embodiment 2

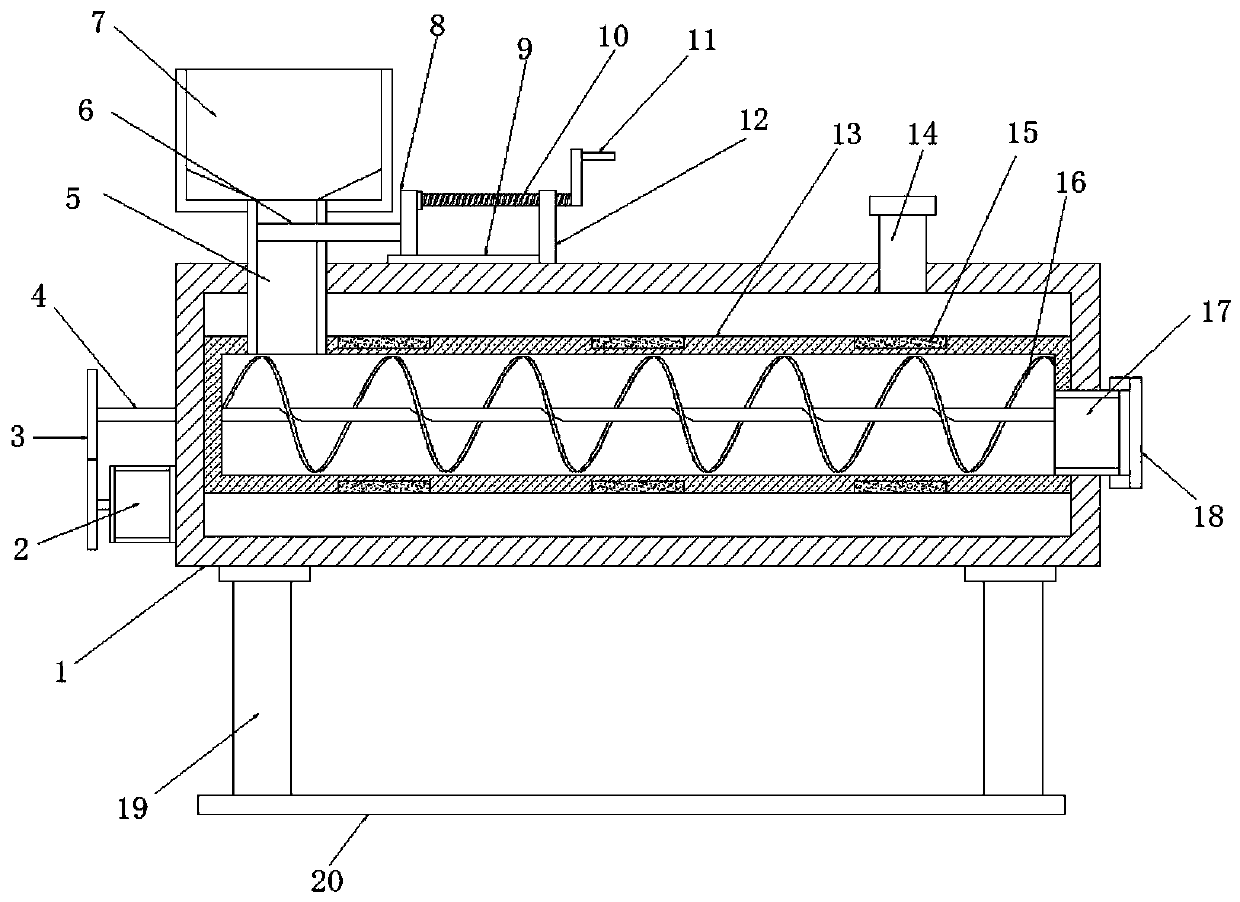

[0027] refer to image 3 , a biodegradable film extruder, the difference between this embodiment and embodiment 1 is that a slide rail 9 and a fixed block 12 are fixed on the outer wall of the top of the incubator 1, and a screw 10 is threadedly inserted on the fixed block 12, and the two ends of the screw 10 A slider 8 and a rotating handle 11 are respectively fixed, the slider 8 is plugged into the slide rail 9 to form a sliding fit, and one side of the slider 8 is fixedly connected with the discharge plate 6 .

[0028] The working principle of this embodiment: the screw 10 can move laterally when the rotating handle 11 is turned, and the screw 10 drives the slider 8 and the discharge plate 6 to move laterally, and then the distance between the discharge plate 6 and the inner wall of the feed pipe 5 can be adjusted. , and carry out the limiting function of the unloading plate 6, the slide rail 9 can play the role of limiting and guiding when the slider 8 moves laterally, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com