IGBT and manufacturing method thereof

An ion and target area technology, applied in electrical components, transistors, circuits, etc., can solve the physical properties of limited element boron, limit the further improvement of IGBT performance, etc. The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

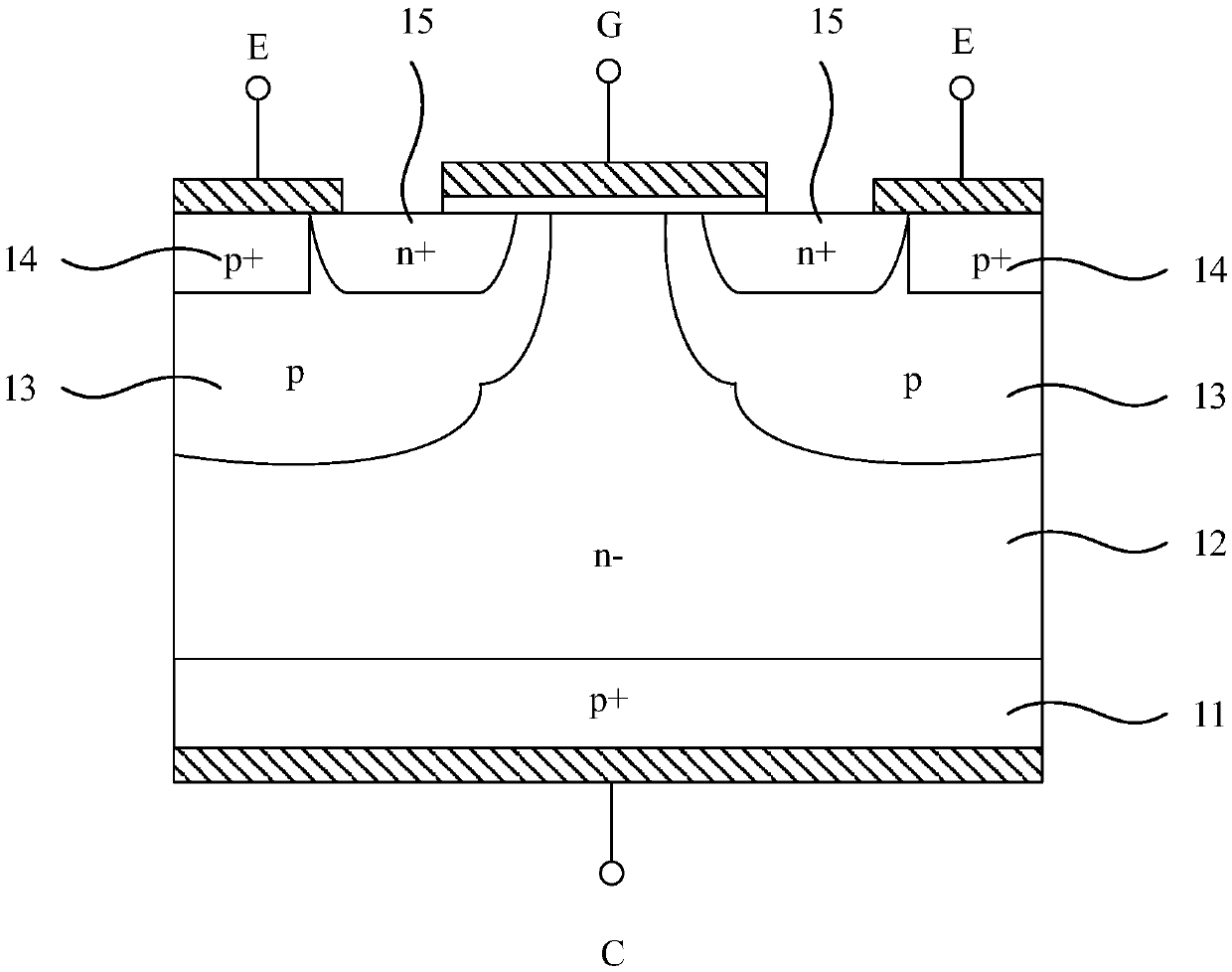

[0028] This embodiment provides an IGBT, figure 1 A schematic structural diagram of this embodiment is shown. see figure 1 , the IGBT of this embodiment includes from bottom to top:

[0029] The collector electrode C on the back of the IGBT, the P-type substrate 11, the N-type drift region 12, the P-type well region 13 located at both ends of the N-type drift region 12, the P-type source region 14 above the P-type well region 13, and the N-type Source region 15 , emitter E located above P-type source region 14 and part of N-type source region 15 , gate G located above part of N-type source region 15 , part of P-type well region 13 and part of N-type drift region 12 .

[0030] In the IGBT of this embodiment, the target region includes at least one of the P-type substrate 11, the P-type well region 13, and the P-type source region 14. In this embodiment, the doping impurities in the target region have a diffusion coefficient greater than that of boron ions. The first ions, sp...

Embodiment 2

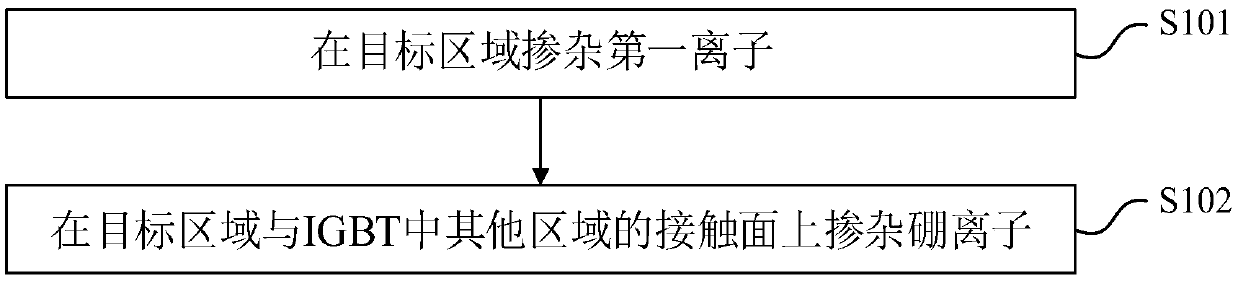

[0035] This embodiment provides a method for manufacturing an IGBT, which is used to manufacture the IGBT of Embodiment 1, figure 2 A flowchart of this embodiment is shown. see figure 2 , the method of this embodiment includes:

[0036] S101. Doping first ions in the target region;

[0037] S102 , doping boron ions on the contact surface between the target region and other regions in the IGBT.

[0038] Therefore, according to the selection of the target region in Embodiment 1, to specifically form the corresponding P-type substrate 11, P-type well region 13, and P-type source region 14, wherein, the first ions can be obtained through, but not limited to, ion implantation, diffusion, and evaporation. , Sputtering in any way to dope into the target area. In addition, boron ions can also be doped to a specific contact surface via but not limited to the above-mentioned methods, so as to avoid metal contamination caused by doped metal ions.

Embodiment 3

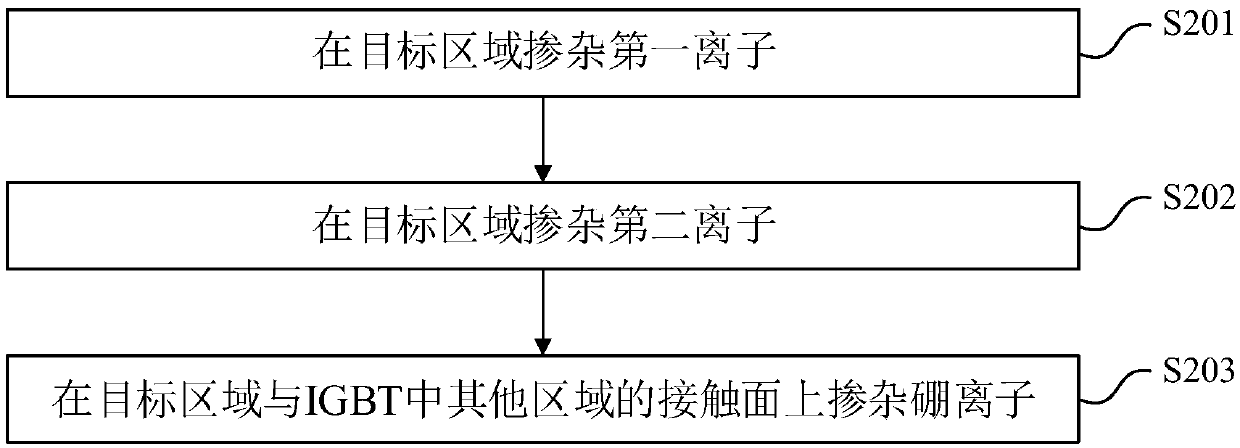

[0040] This embodiment provides an IGBT on the basis of Embodiment 1. Specifically, the improvement of the IGBT of this embodiment compared with Embodiment 1 lies in that the target region of this embodiment, that is, at least one of the P-type substrate 11, the P-type well region 13, and the P-type source region 14 , in addition to being doped with first ions, also doped with second ions, the diffusion coefficient of the second ions is not less than the diffusion coefficient of boron ions, specifically, the second ions can be but not limited to boron ions, aluminum ions , gallium ions, indium ions, thallium ions.

[0041] In this embodiment, the first ion is preferably aluminum ion, and the second ion is preferably gallium ion, or, the first ion is preferably gallium ion, and the second ion is preferably aluminum ion. In addition, the first ions and the second ions can be doped with each other or distributed in different layers according to specific applications. The doping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com