Silicon-based micro LED chip and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of damage to GaN materials and Micro LED chips, affect the reliability of LED chips, and chip leakage, so as to reduce lattice mismatch, Conducive to matching adjustment and improving the effect of crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

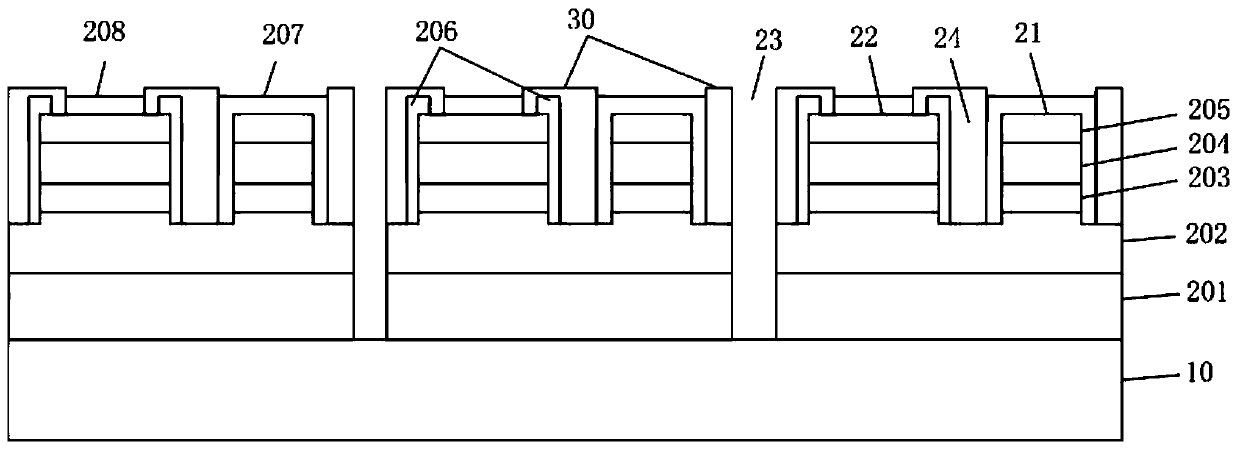

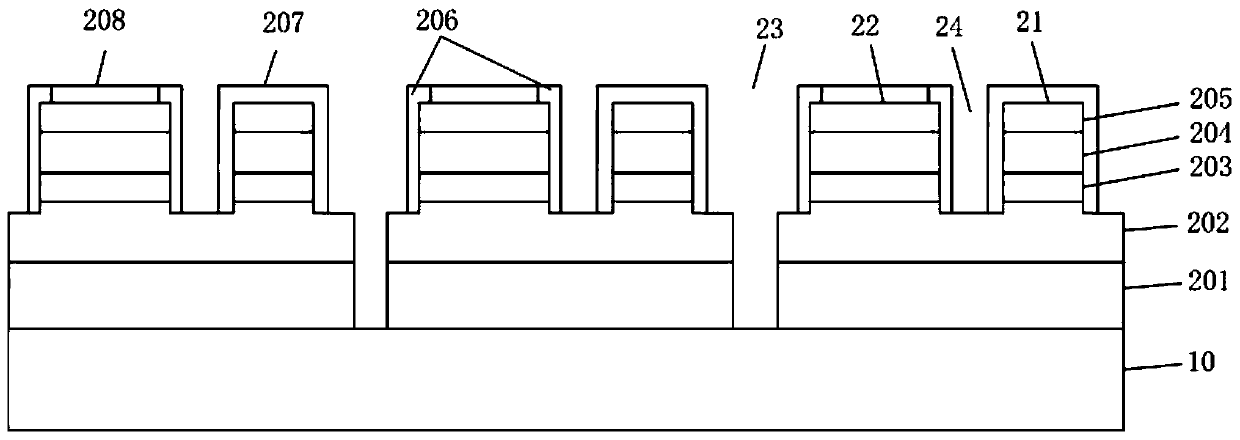

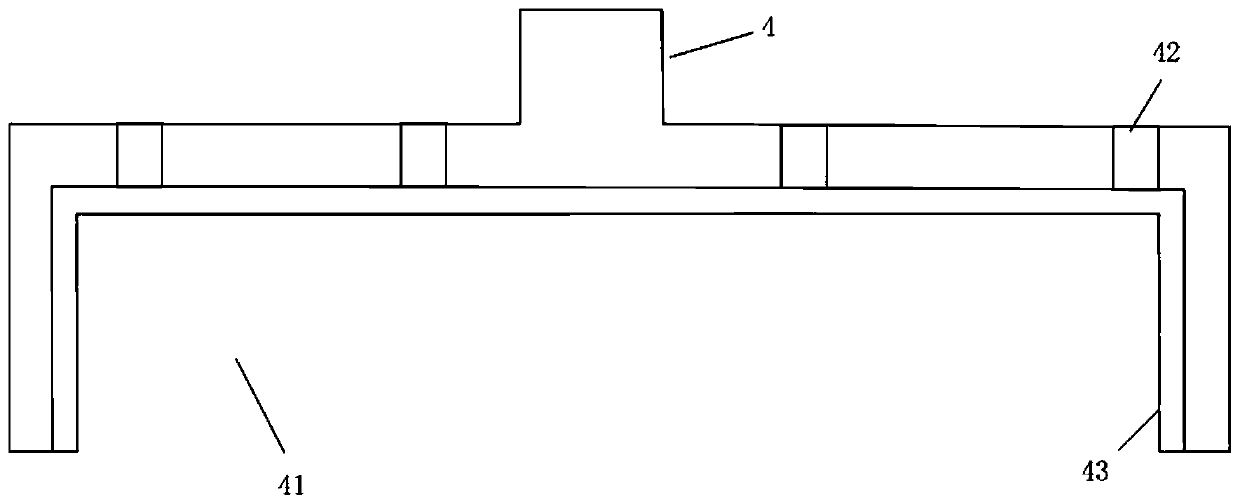

[0045] see figure 1 , a silicon-based micro-LED chip provided by the present invention includes a silicon substrate 10, several light-emitting structures 20, cutting grooves 23, and an organic insulating layer 30. The cutting grooves 23 are arranged between the light-emitting structures 20, and the light-emitting structures 20 apart.

[0046]The light emitting structure 20 includes an etch barrier layer 201, a first semiconductor layer 202, an active layer 203, a second semiconductor layer 204 and an isolation groove 24, and the etch barrier layer 201 is disposed on the silicon substrate 10 and the first semiconductor layer Between the layers 202 , the isolation groove 24 is etched to the first semiconductor layer 202 to divide the light emitting structure 20 int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com