High efficient energy-saving coating technology and equipment of double side coated release paper

A high-efficiency energy-saving, release paper technology, applied in paper, papermaking, metal processing, etc., can solve the problems of high energy consumption in the drying process, increased production costs, and huge energy consumption, so as to shorten the processing process and reduce production capacity. Consumption and equipment costs, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

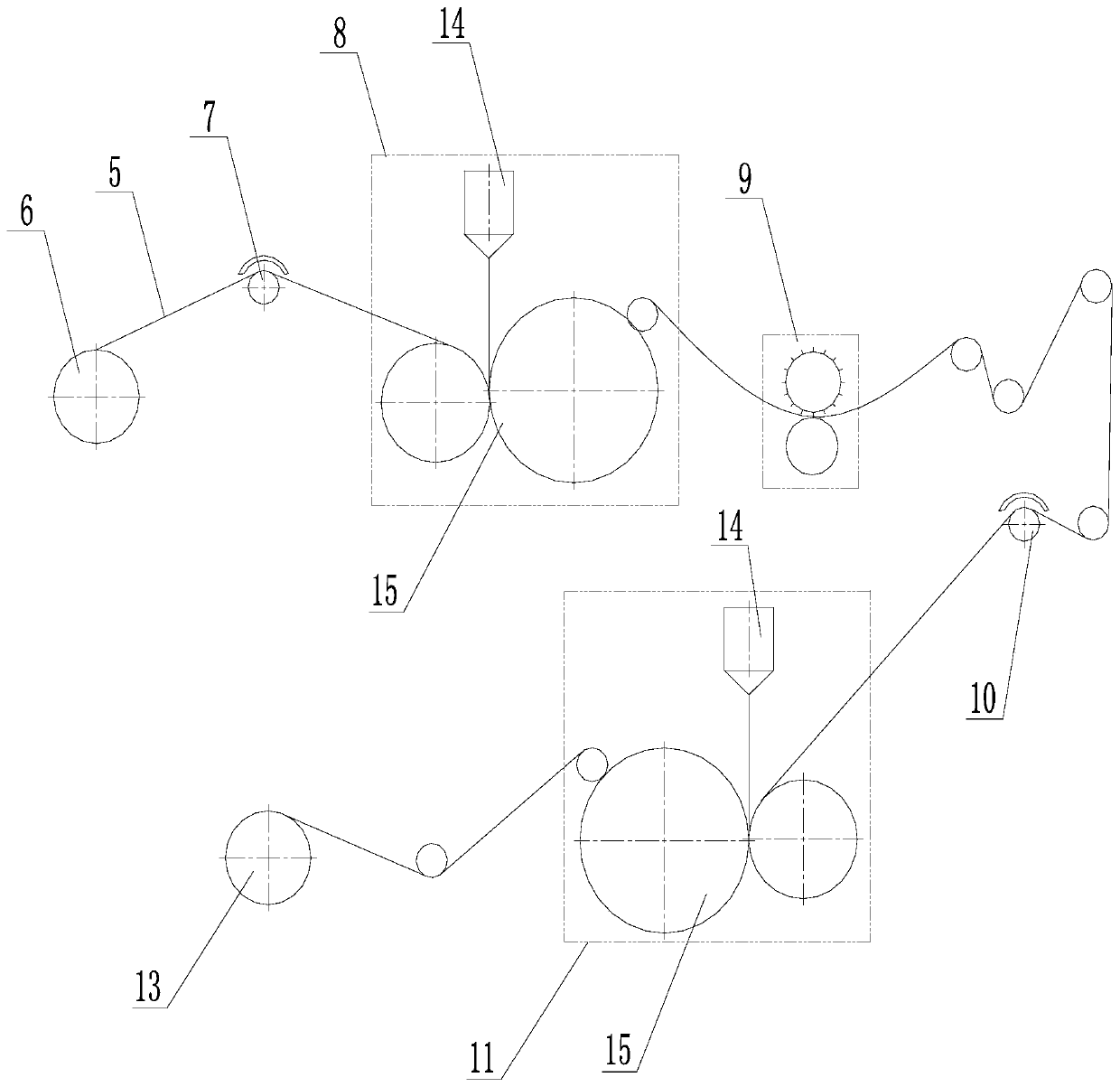

[0041] A kind of high-efficiency and energy-saving double-sided coating release paper coating process of this embodiment, such as figure 1 shown, including the following steps:

[0042] (1) After the unwinding mechanism 6 releases the base material 5, the front corona device 7 is used to polarize one side of the base material, and after completion, the polarized side of the base material is sprayed by the front surface coating device 8. Membrane, forming the frontal barrier;

[0043] (2) puncture the front isolation layer by the punching device 8, so that air-permeable micropores are formed on the front isolation layer;

[0044] (3) Carry out polarization treatment to the other side of base material by back side corona device 10, carry out film coating by back side coating device 11 after completion, form back side isolation layer;

[0045] (4) Rewinding is carried out by the winding mechanism 13 after completion.

[0046] During the extrusion coating process, due to the addi...

Embodiment 2

[0058] A kind of high-efficiency and energy-saving double-sided coating release paper coating process of this embodiment, such as Figure 6 shown, including the following steps:

[0059] (1) After the unwinding mechanism 6 releases the base material, the front corona device 7 is used to polarize one side of the base material, and after completion, the front side coating device 8 is used to coat the polarized side of the base material. , forming a positive isolation layer;

[0060] (2) Polarization is carried out to the other side of base material by back side corona device 10, after completion, carry out film coating by back side coating device 11, form back side isolation layer;

[0061] (3) Puncture the isolation layer (i.e. the front isolation layer or the back isolation layer) on one side of the base material by the punching device 9, so that air-permeable micropores are formed on the isolation layer;

[0062] (4) Rewinding is carried out by the winding mechanism 13 afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com