Composite fiber with intelligent surface and preparation method and application of composite fiber

A composite fiber and fiber technology, which is applied in the field of fiber materials, can solve the problems of increased conductivity of the fiber matrix, uncomfortable wearing, and failure to achieve mutual integration of conductive devices and fibers, and achieve the effect of stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

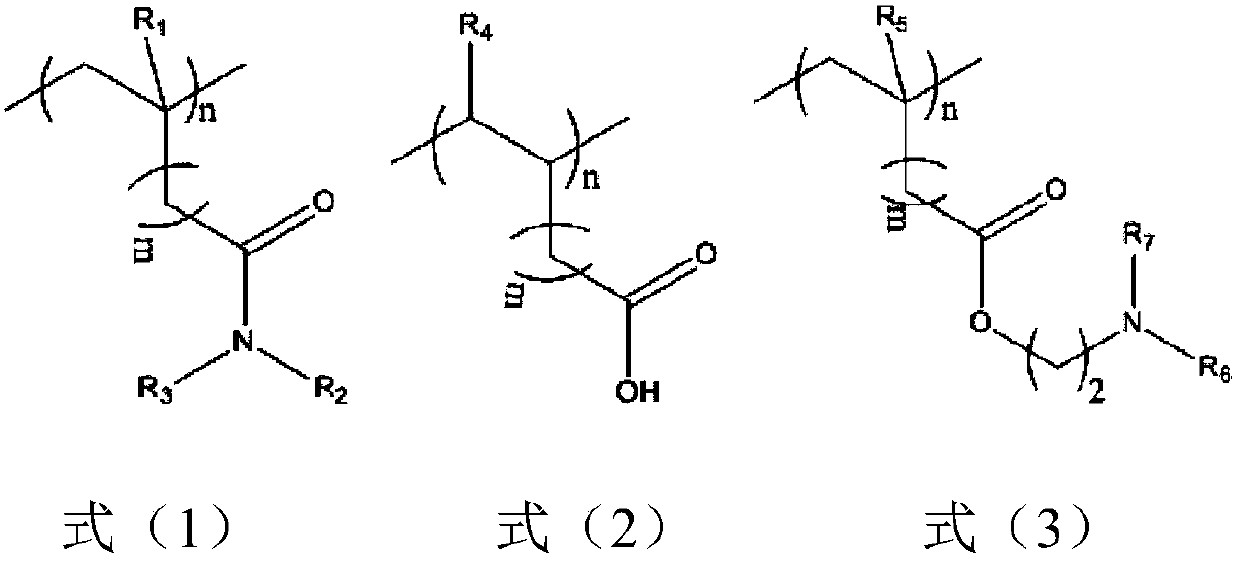

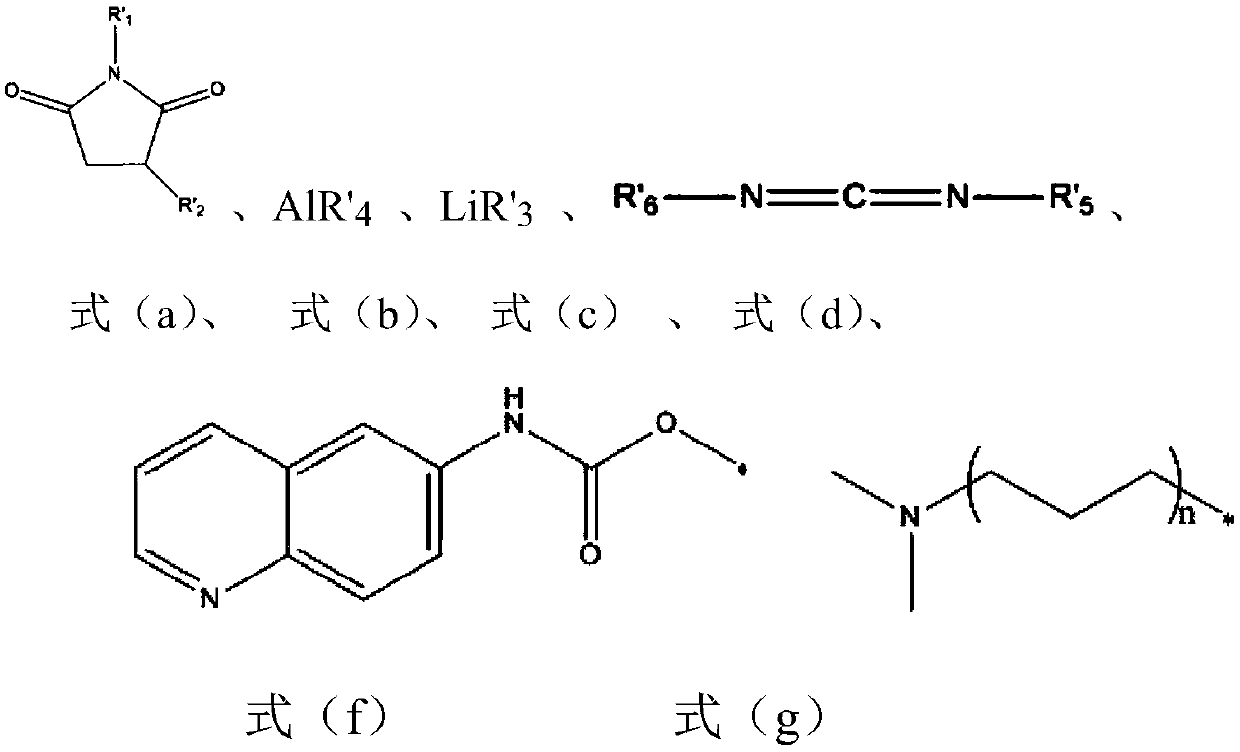

Method used

Image

Examples

Embodiment 1

[0111] Soak PVC fiber in water, ethanol, isopropanol, acetone, n-hexane and other solutions to clean thoroughly, then dry it for use

[0112] Place the dry polyvinyl chloride fiber in an ozone plasma treatment apparatus, adjust the voltage and current to be moderate, treat it in an argon atmosphere for 1 min, and then expose it in air for 30 min to obtain a polyvinyl chloride fiber with a surface modified with hydroxyl groups.

[0113] 1 g of (glycidyl methacrylate / N-isopropylpropionamide) core-shell conductive particles modified with epoxy groups and containing gold particles were dispersed in 500 ml of distilled water. Then add 2 grams of polyvinyl chloride fibers modified with hydroxyl groups, react at 60°C for 5 hours, then take out and wash with ethanol and water to obtain intelligent polyvinyl chloride composite fibers.

[0114] Among them, the particle diameter of conductive particles with a core-shell structure (glycidyl methacrylate / N-isopropylpropionamide) modified w...

Embodiment 2

[0116] The polypropylene fiber is soaked in tetrahydrofuran, ethanol and other solutions successively, fully cleaned, and then dried for use.

[0117] Place the dry polypropylene fiber in an ozone plasma treatment apparatus, adjust the voltage and current to a moderate level, treat it in an argon atmosphere for 1 min, and then expose it in air for 60 min to obtain a polyvinyl chloride fiber with carboxyl groups on the surface.

[0118] 1 g was modified with thiol groups and contained SiO 2 The conductive particles of poly-N-isopropylpropionamide were dispersed in 200mL of decane, 2g of polyvinyl chloride fibers modified with carboxyl groups were added, reacted at 70 degrees Celsius for 4 hours, and then separated and washed to obtain polypropylene composite fibers. Modified with mercapto groups and contains SiO 2 The conductive particles of poly-N-isopropylpropionamide are 400nm, and the diameter of the carboxyl-containing polypropylene fiber matrix is 40μm.

Embodiment 3

[0120] Soak the polycaprolactam fiber in water, ethanol, isopropanol, acetone, tetrahydrofuran and n-hexane in order to fully clean, and then dry it for use;

[0121] The dried polycaprolactam fiber sample was placed in a plasma processor, and the voltage and current were adjusted to 50V and 2A respectively, so that the polycaprolactam fiber sample was treated in an argon atmosphere for 1min, and then exposed in air for 30min to obtain a surface modified Hydroxyl polycaprolactam fiber;

[0122] Then refer to "Graft compounding of polysiloxane / coupling-modified titanium sol and thin loading on the surface of polyester fiber, doctoral dissertation, Cao Jun, Zhejiang Sci-Tech University", for the obtained surface modified polycaprolactam fiber with hydroxyl groups and The silane coupling agent MSP reacts to obtain polycaprolactam fibers with double bonds on the surface;

[0123] Disperse 1 g of poly(N,N-dimethylaminoethyl methacrylate) hybrid conductive particles containing sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com