An In Situ Controllable Bonding Method of Amorphous Nanowires and Porous Films

A technology of porous film and nanowire, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effect of strong high-precision characteristics, strong flexibility and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

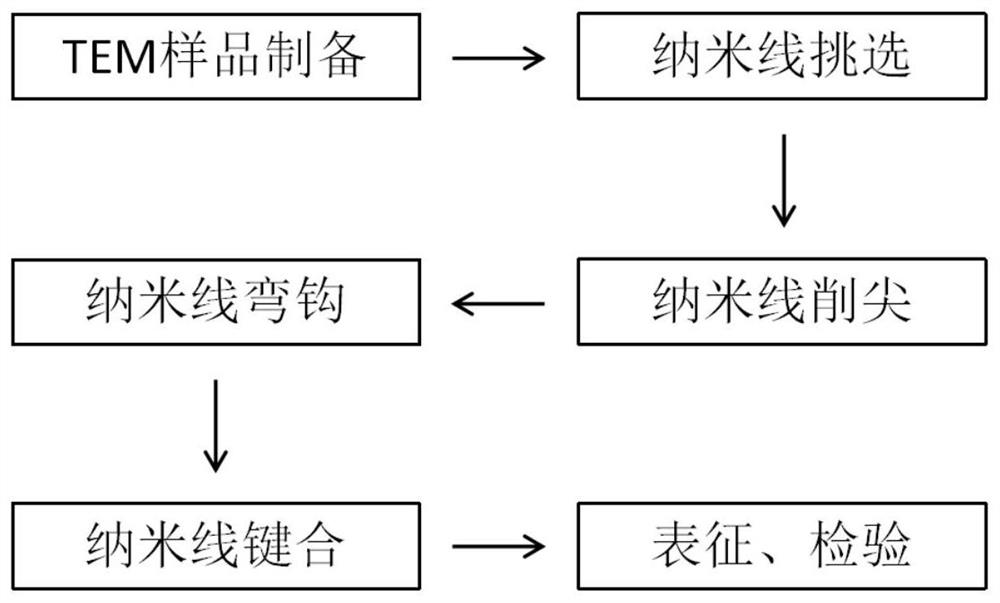

Method used

Image

Examples

Embodiment 1

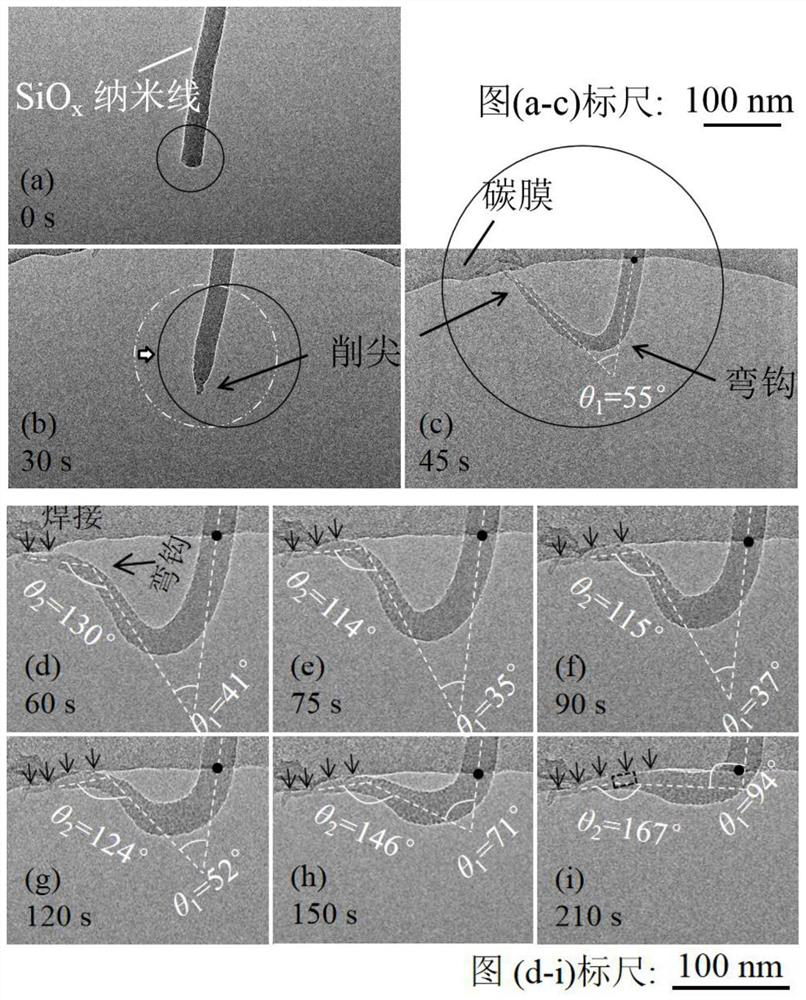

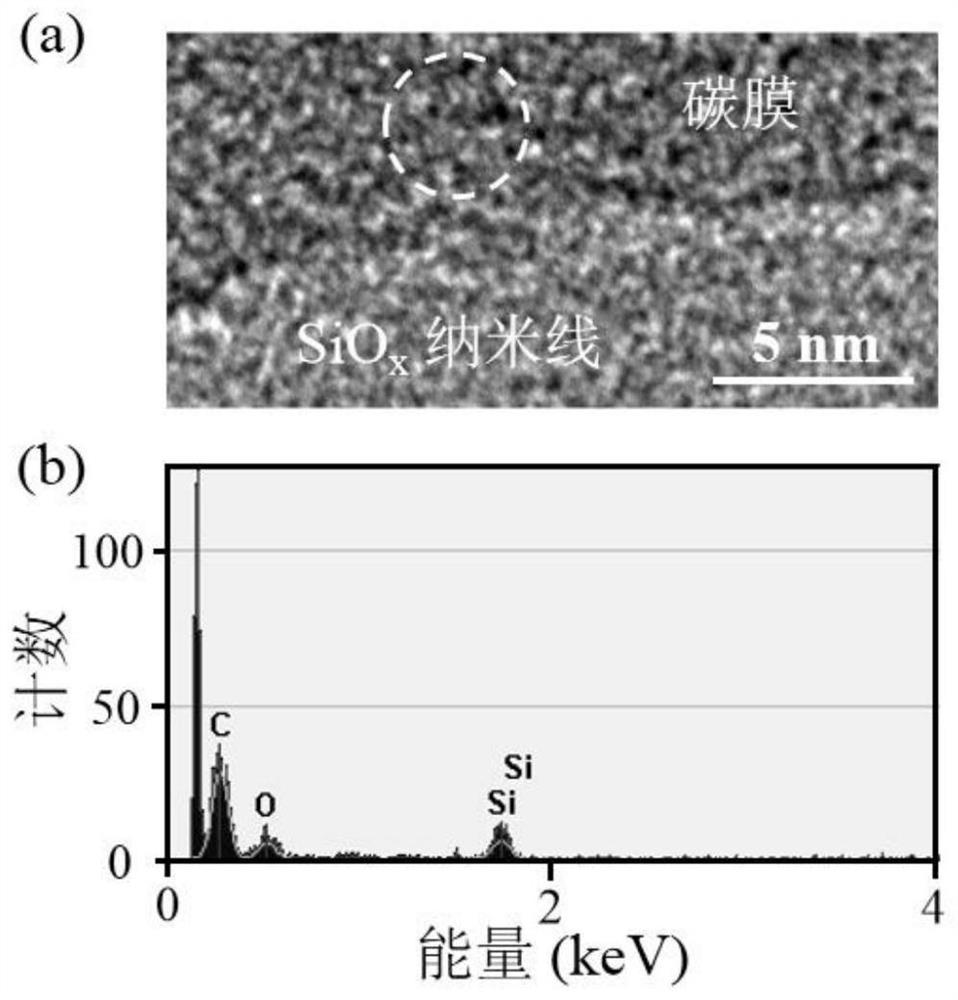

[0027] Example 1: Brittle amorphous SiO x Bonding of Nanowires and Porous Carbon Films with TEM Microgates

[0028] 1) TEM sample preparation:

[0029] Scrape off a little SiO from the silicon wafer substrate with a blade x Nanowire powder (x Drop 2 drops of the ethanol solution of the nanowires onto the porous carbon film with a copper grid micro-grid. The pore diameter of the porous carbon film is about 1000 nm, and the TEM sample is obtained after standing for 15 minutes to dry.

[0030] 2) Nanowire screening:

[0031] Load the TEM sample into a JEOL JEM-2100 transmission electron microscope with an accelerating voltage of 200kV, and then select the nanowire segment to be irradiated. Such as figure 2 As shown in (a), the nanowire segment contains free ends, and the free ends protrude into the pores of the porous carbon film; the TEM observation magnification of 50,000× is appropriate, and the overall morphology and main details of the nanowire segment can be observed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com