Knife sharpening stone

A whetstone and roller technology, used in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve problems such as inconvenience, and achieve the effect of improving grinding efficiency and preventing slipping and non-rotating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

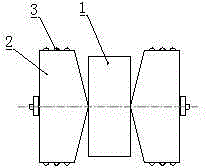

[0008] As shown in the drawings, it includes a whetstone 1, a roller 2, and an anti-skid knurled layer 3. A roller 2 is provided on both sides of the disc-shaped whetstone 1, and the two rollers 2 are close to the side of the whetstone 1. It is conical, and the circumferential surface of the roller 2 is provided with an anti-slip knurl layer 3 .

[0009] Put the knife edge of the kitchen knife in the gap between the roller 2 and the whetstone 1 on the left so that the right edge of the knife edge touches the whetstone 1, the knife moves back and forth to drive the roller 2 and the whetstone 1 to roll as a whole, and then insert the knife edge into the gap on the other side Roll to sharpen the cutting edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com