Grape shoot pinching machine

A technology of new shoots and grapes, applied in cultivation, agriculture, application, etc., can solve the problems of inconvenient new shoots, inconvenience, staff injury, etc., and achieve the effect of continuity, reducing damage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

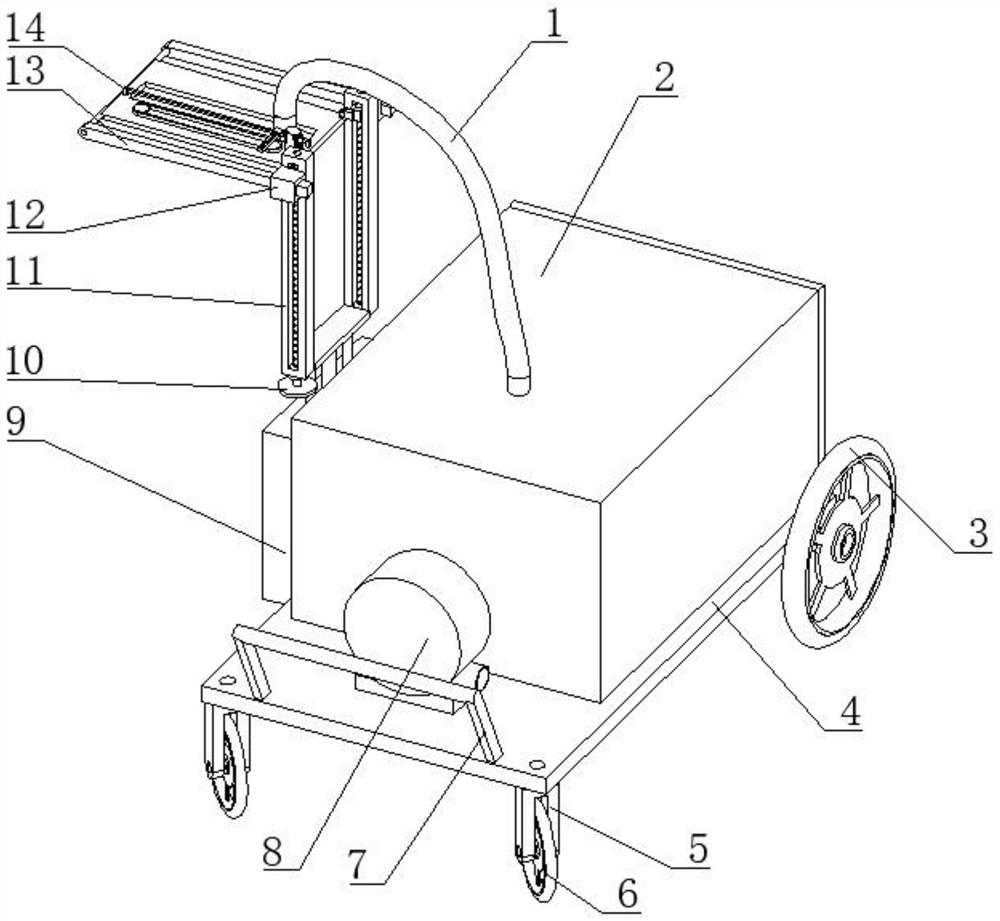

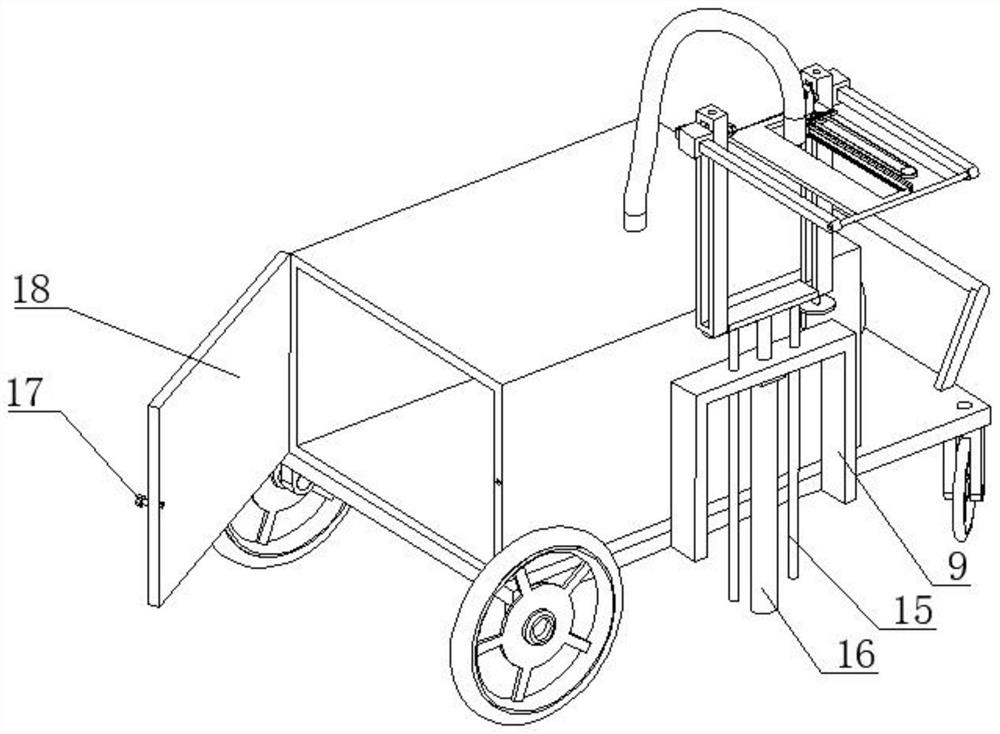

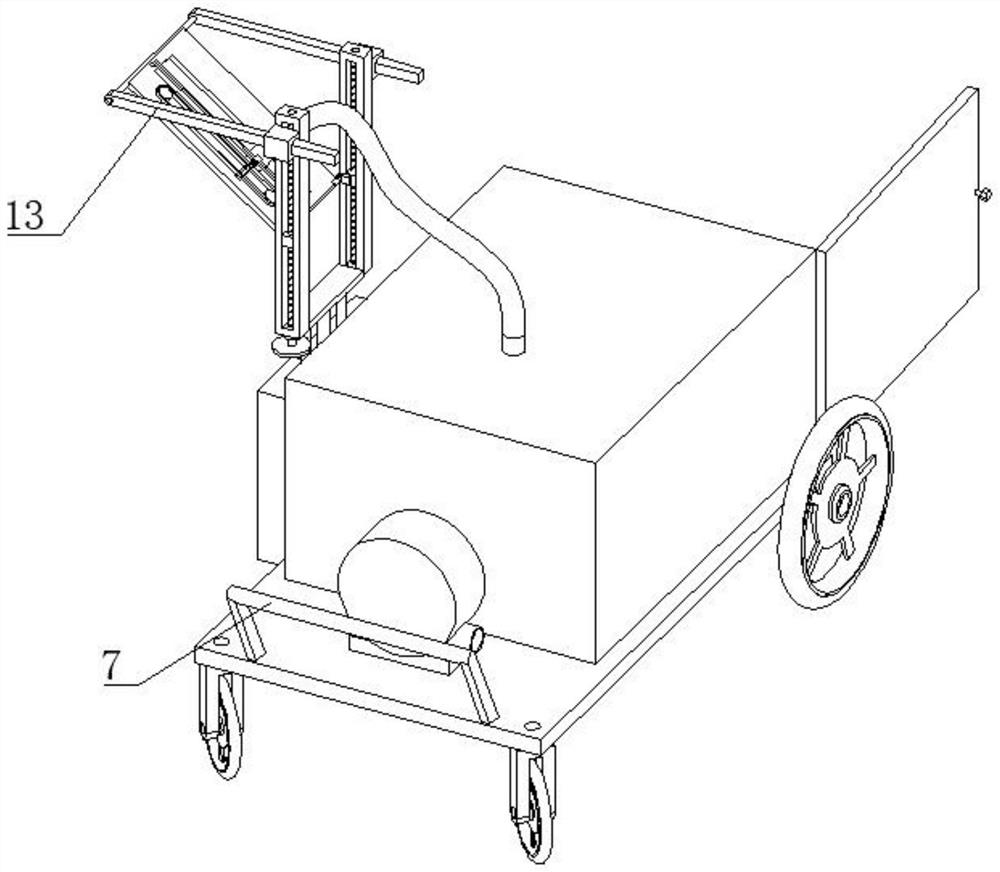

[0040] Embodiment 1: The present invention includes a bottom plate 4,

[0041] The upper side of the bottom plate 4 is fixedly connected to the lower side of the box body 2, and the middle part of one side of the box body 2 is fixedly communicated with the suction end of the negative pressure pump 8, and the lower side of the negative pressure pump 8 is fixedly connected to the In the middle of one end of the upper side of the bottom plate 4, a filter plate 44 is provided in the box body 2, and the outer sides of the filter plate 44 are respectively fixedly connected to the inner wall of the box body 2, and one end of the box body 2 is hingedly connected to the cover plate One end of 18, the top wire 17 passes through the middle part of one side of the cover plate 18, and the top wire 17 is threadedly connected in the threaded hole provided at the other end middle part of the box body 2;

[0042]The middle part of one side of the base plate 4 is fixedly connected to one side o...

Embodiment 2

[0053] Embodiment 2: This embodiment is a further elaboration on the basis of Embodiment 1. The upper edge of the bottom plate 4 is fixedly connected to the two ends of the U-shaped push rod 7 respectively.

[0054] The staff can directly hold the U-shaped push rod 7 and move the device, which makes the whole operation more convenient and saves time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com