Extrusion tap grinding machine and using method thereof

A technology for extruding taps and grinding machines, which is applied in the direction of grinding bed, grinding machine parts, grinding frame, etc., and can solve the problems of complex processing operations, low processing efficiency and complex mechanical structure of extrusion taps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

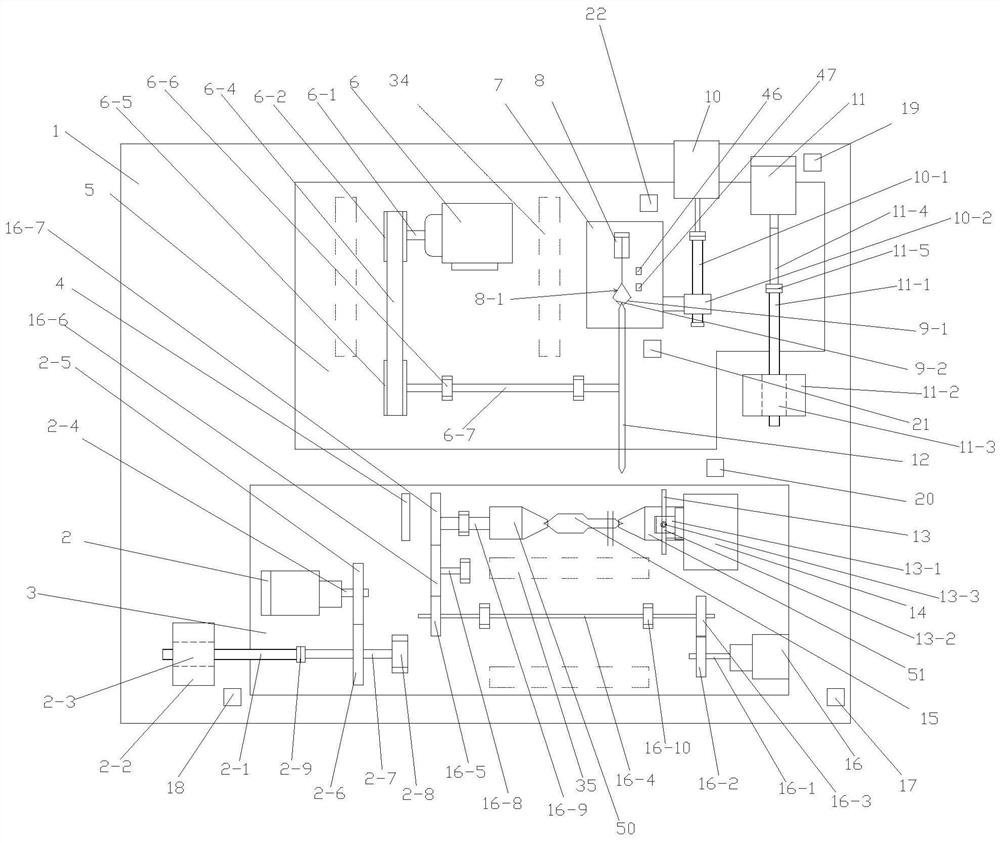

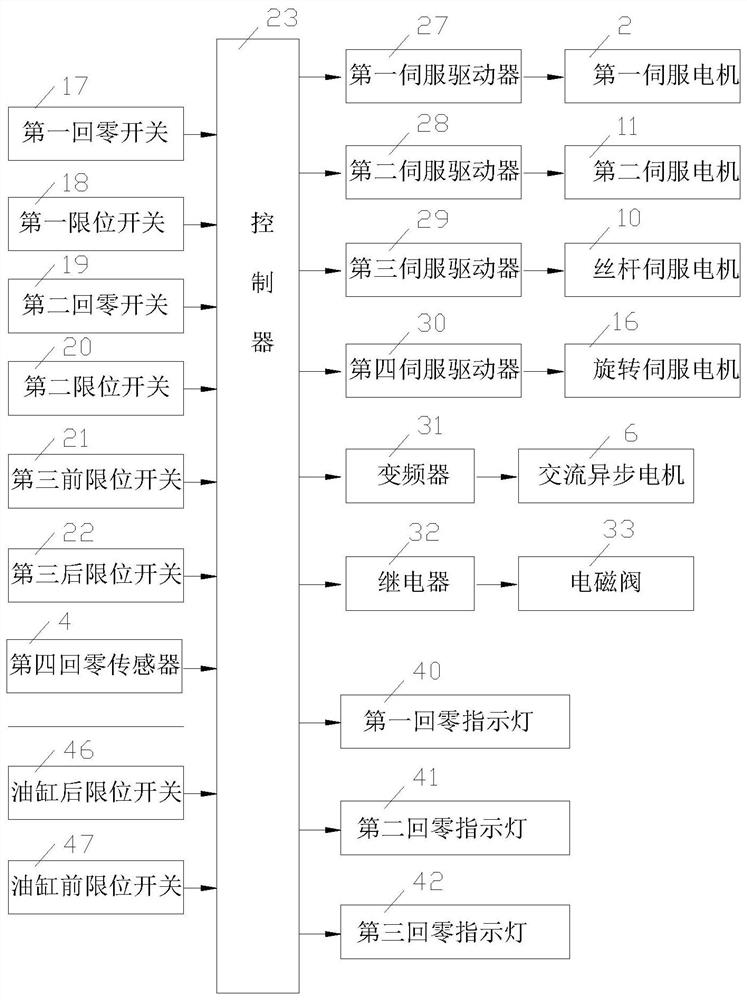

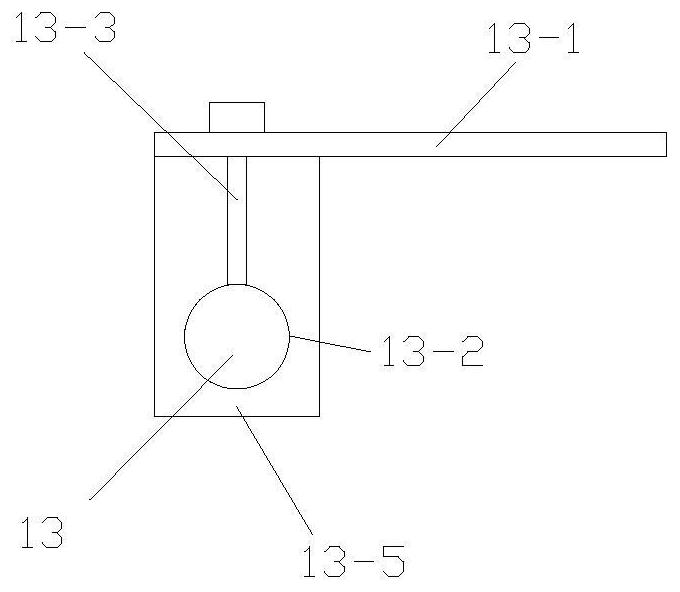

[0165] Such as Figure 1 to Figure 3 The shown extrusion tap grinding machine includes a bed base 1, a longitudinal sliding mechanism and a lateral sliding mechanism arranged on the bed base 1, and a machine arranged on the longitudinal sliding mechanism and driving the workpiece 15 to rotate The rotation mechanism and the grinding wheel dressing mechanism arranged on the lateral sliding mechanism and the monitoring module arranged on the bed base 1;

[0166] The longitudinal sliding mechanism includes a longitudinal guide rail 35 arranged on the bed base 1, a longitudinal slide plate 3 installed on the longitudinal guide rail 35, and a longitudinal drive module that drives the longitudinal slide plate 3 to slide along the longitudinal guide rail 35;

[0167] The lateral sliding mechanism includes a lateral guide rail 34 arranged on the bed base 1, a lateral slide plate 5 installed on the lateral guide rail 34, and a lateral drive module that drives the lateral slide plate 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com