Automatic steel slag drossing machine

A technology of slag removal machine and steel slag, which is applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc. It can solve the problems of operator fatigue, low slag removal efficiency, and the operator can not always maintain the optimal state, so as to achieve precise control , Improve the efficiency of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

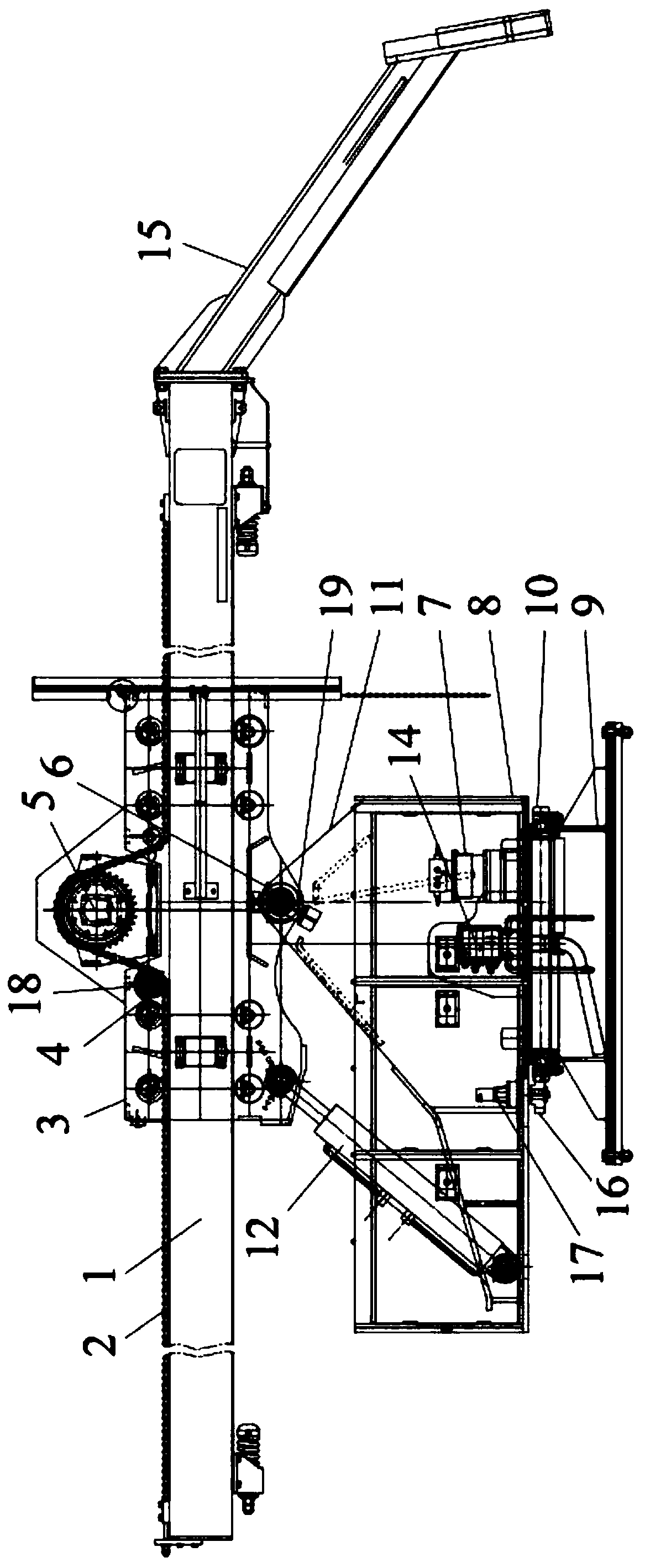

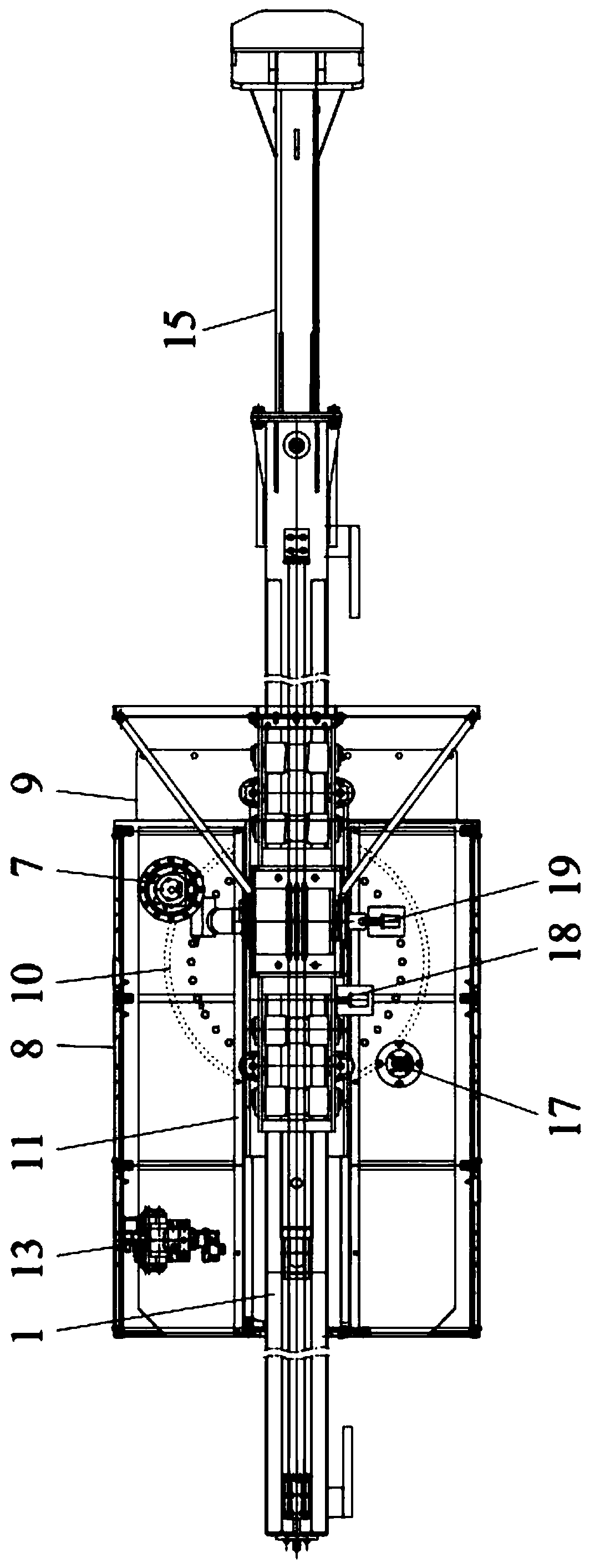

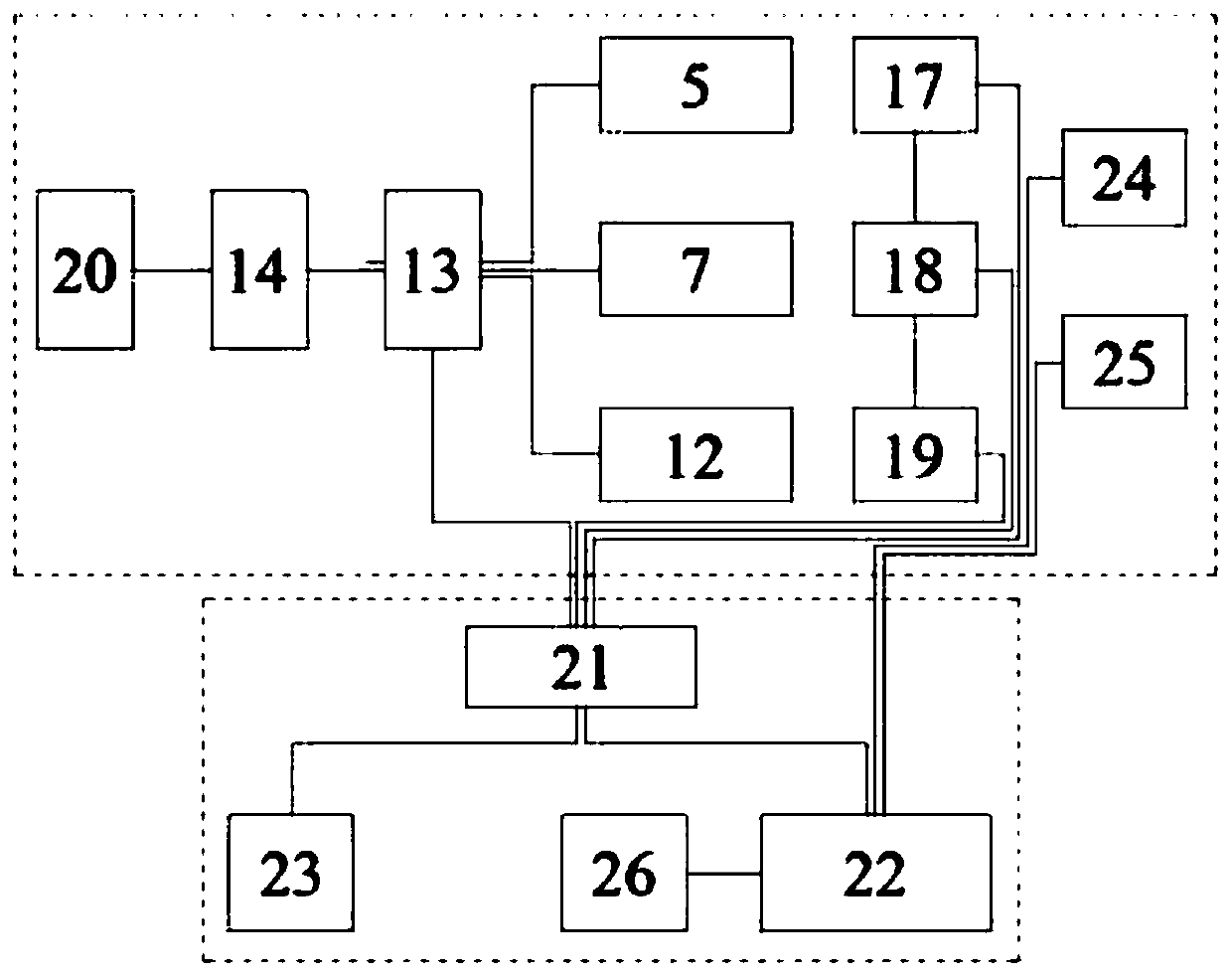

[0021] Such as Figure 1 to Figure 3 As shown, the present embodiment provides an automatic steel slag removal machine, which includes a base 9, a rotary platform 8 installed on the base 9, a support frame 11 fixed on the rotary platform 8, and a slide hinged to the top side of the support frame 11. Sleeve 3, the slag removal rod 1 pierced in the sliding sleeve 3, the slag removal head 15 fixed on the front side of the slag removal rod 1, the rotary deceleration motor 7 used to drive the rotary platform 8 to drive the slag removal head 15 to swing left and right , the telescopic deceleration hydraulic motor 5 used to drive the slag removal rod 1 to move forward and backward along the sliding sleeve 3 to drive the slag removal head 15, and the up and down swing oil cylinder 12 used to drive the sliding sleeve 3 to drive the slag removal head 15 to swing up and down. The control valve table 13 on the platform 8 is used to control the rotary deceleration motor 7, the telescopic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com