Lithium battery anode recycled material dry purification separation and regeneration method and obtained lithium battery anode recycled material

A technology for recycling materials, purification and separation, applied in battery recycling, chemical instruments and methods, recycling technology, etc., can solve problems such as damaged structures, and achieve good performance, high purity, morphology and crystal form recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1) 4kg cut into 1*1cm 2 The 523 leftovers were divided into 4 burning bowls, and de-powdered at 450°C / 1h under air atmosphere.

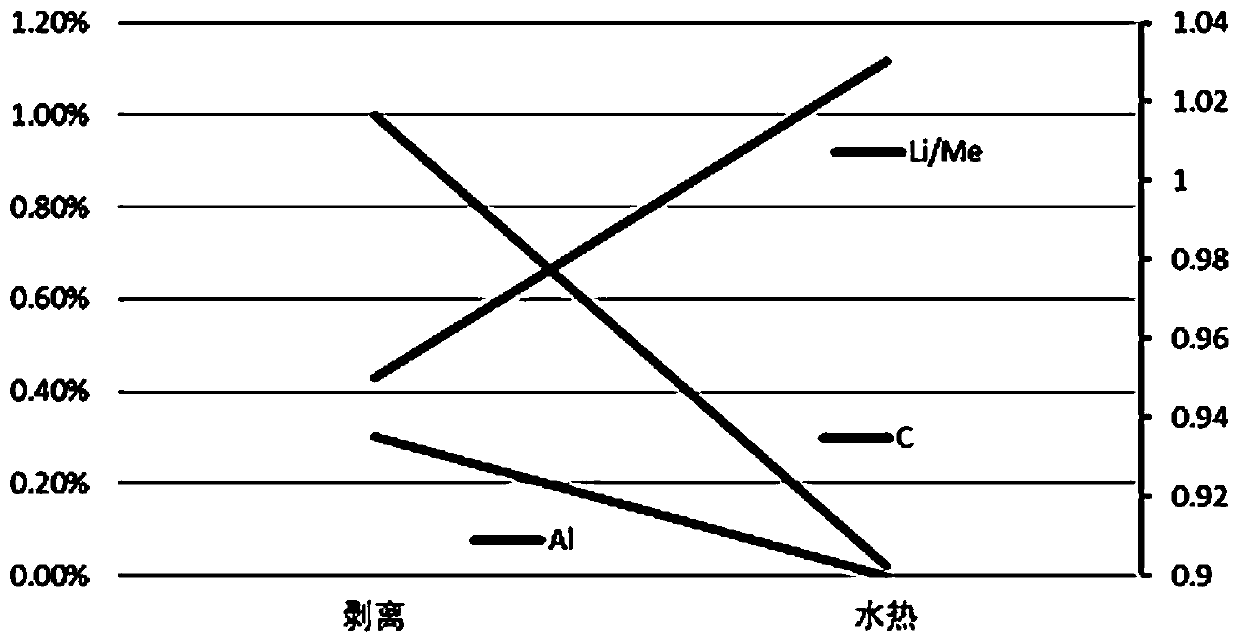

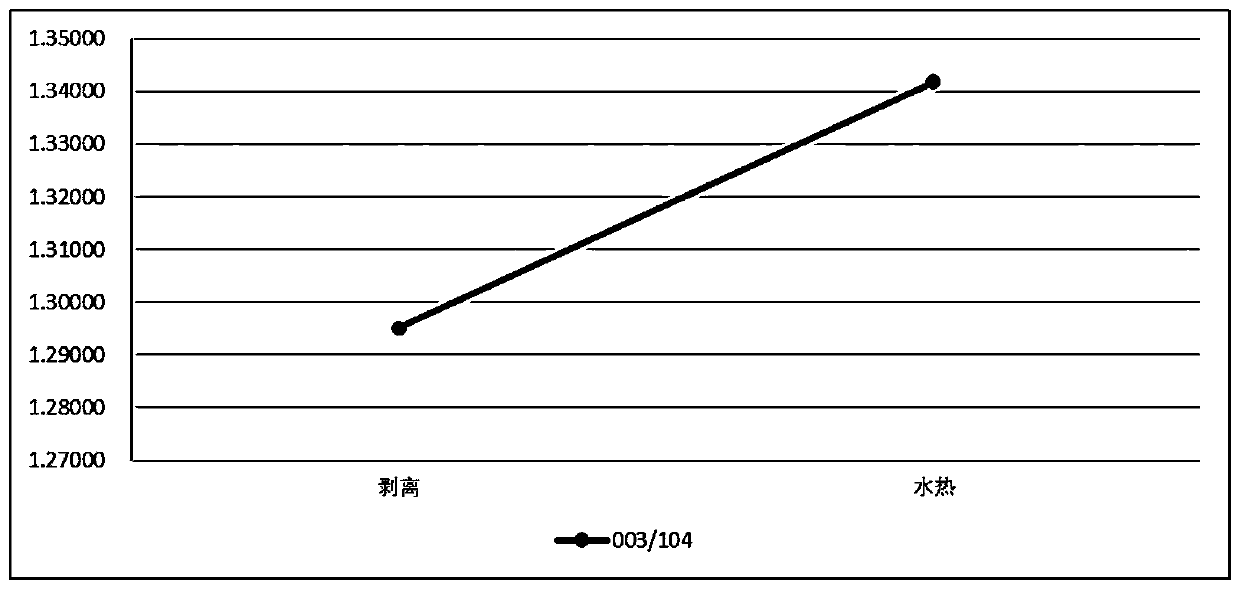

[0060] 2) After shaking for 5 minutes, the de-powdering efficiency reaches 98%, which is considered to be complete. The Al content is about 0.3%, the C content is about 1%, and Li / Me=0.95.

[0061] 3) With 4mol / L LiOH, under the condition of 220℃ / 4h, 100g of 523 powder is hydrothermally supplemented with lithium, where n Li+ / n 正极材料 =1:1.

[0062] 4) After cooling to room temperature, filter, and vacuum-dry the filter cake at 130°C / 4h. The test results show that the Al content is lower than the ICP detection limit, the C content is 0.019%, and Li / Me=1.03.

[0063] 5) After grinding and crushing, pass through a 300-mesh sieve to collect the powder.

[0064] 6) Put the powder into a bowl, and sinter at 680°C / 8h in an oxygen atmosphere to obtain Restoration Material 1.

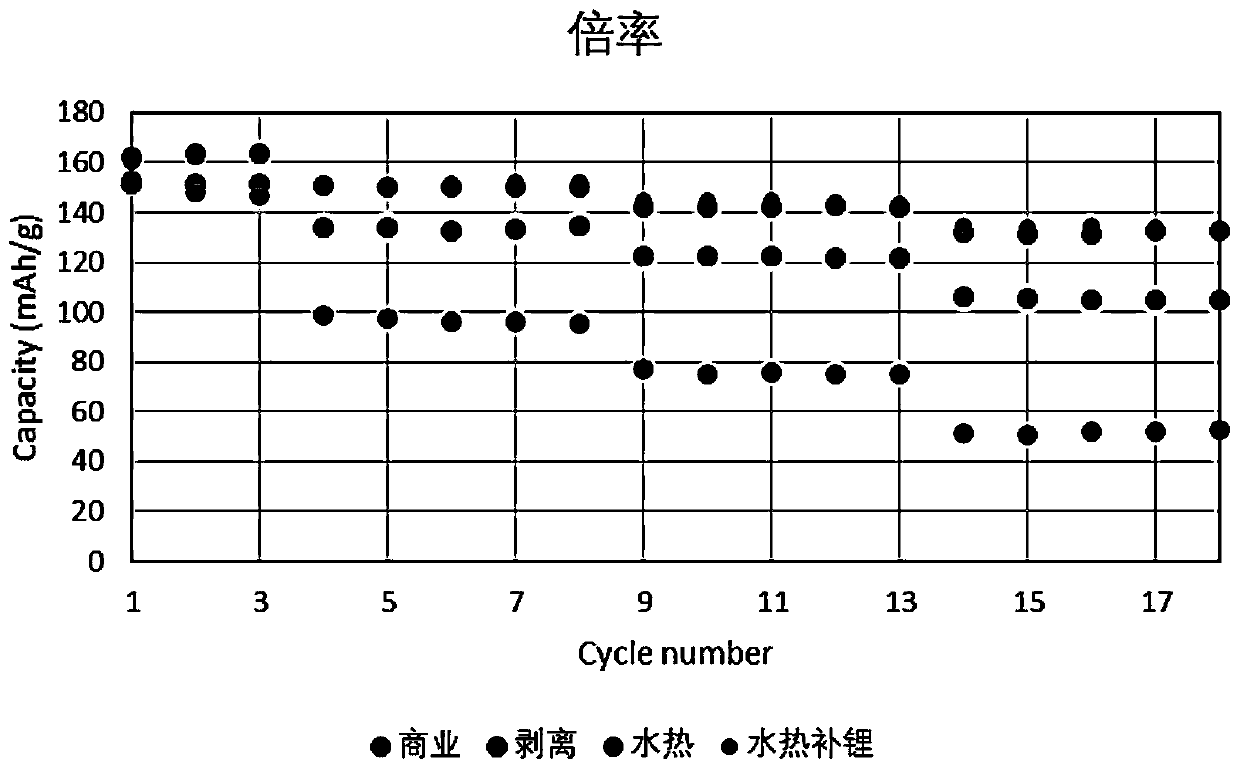

[0065] 7) The restoration material 1 is tested, and the results are as...

Embodiment 2

[0070] 1) Cut to 2*2cm 2 100g 523 leftovers of the size were placed in a crucible (stacked thickness is about 1cm), and then the PVDF was invalidated in the air atmosphere of the tube furnace at 400°C / 2h.

[0071] 2) The positive electrode recovery material was manually knocked off from the thermally expired PVDF pole piece, and passed through a 300-mesh sieve. The de-powdering efficiency is greater than 98%, and it is considered that the de-powdering is complete. The Al content obtained from the test is about 0.236%, the C content is about 1%, and Li / Me=0.95.

[0072] 3) With 2mol / L LiOH, under the condition of 220°C / 4h, the above powder is hydrothermally supplemented with lithium, where n Li+ / n 正极材料 =1:2.

[0073] 4) After cooling to room temperature, filter, and vacuum-dry the filter cake at 130°C / 4h. The test results show that the Al content is lower than the ICP detection limit, the C content is 0.019%, and Li / Me=1.016.

[0074] 5) After grinding and crushing, pass ...

Embodiment 3

[0078] 1) 100g cut into 10*10cm 2 The 523 leftovers are placed in a burning bowl in a layer-by-layer manner, and heat-treated at 600°C for 0.5h in a nitrogen atmosphere to make the adhesive invalid.

[0079] 2) The positive electrode powder was manually knocked off, and the powder removal efficiency reached 98%, which was considered to be complete. The Al content was about 0.226%, the C content was about 1%, and Li / Me=0.95.

[0080] 3) With 4mol / L LiOH, under the condition of 180℃ / 4h, the 523 powder is hydrothermally supplemented with lithium, where n Li+ / n 正极材料 =1:4, the solid-liquid ratio is 1:1.

[0081] 4) After cooling to room temperature, filter, and vacuum-dry the filter cake at 130°C / 4h. The test results show that the Al content is lower than the lower limit of ICP detection, the C content is 0.019%, and Li / Me=1.01.

[0082] 5) After grinding and crushing, pass through a 300-mesh sieve to collect the powder.

[0083] 6) Put the powder into a bowl, and sinter at 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com