Copper-cobalt bimetal-organic framework material based on 2, 5-dihydroxy terephthalic acid ligand as well as preparation method and application of copper-cobalt bimetal-organic framework material

A technology of hydroxyterephthalic acid and organic framework, which is applied in the field of copper-cobalt bimetallic-organic framework materials and its preparation, can solve the problems of increased processing cost and low catalyst activity, achieve short reaction time, simple preparation method, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

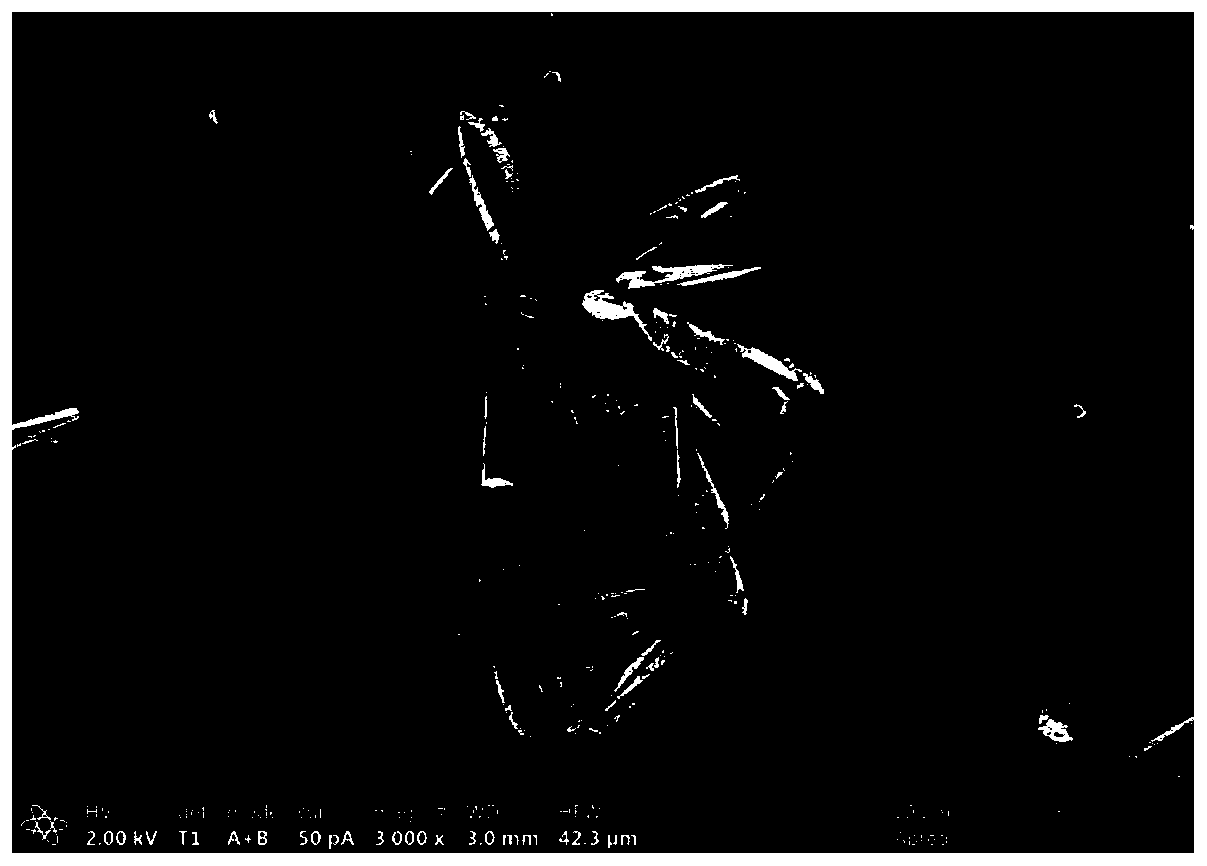

[0035] Preparation of Copper-Cobalt Bimetallic-Organic Framework Materials

[0036] (1) Preparation of precursor solution: 0.873g (3mM) Co(NO 3 ) 2 ·6H 2 O, 0.563g (3mM) Cu(NO 3 ) 2 ·6H 2 O and 0.498 g (3 mM) 2,5-dihydroxyterephthalic acid (DTPA) were dissolved in 60 mL of a mixture of N,N-dimethylformamide (DMF) and ethanol (DMF:ethanol=1:1), The above mixed solution is stirred until completely dissolved to obtain a precursor solution;

[0037] (2) Copper-cobalt bimetallic-organic framework material based on 2,5-dihydroxyterephthalic acid ligand: transfer the precursor solution obtained in step (1) to a 100 mL polytetrafluoroethylene-lined autoclave , put the reaction kettle into a program-controlled oven, and solvothermally react at 110 °C for 24 hours; cooled, naturally cooled to room temperature, filtered by a vacuum pump, and repeated with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water. Wash to obtain brown precipitate; put the precipitate into a...

Embodiment 2

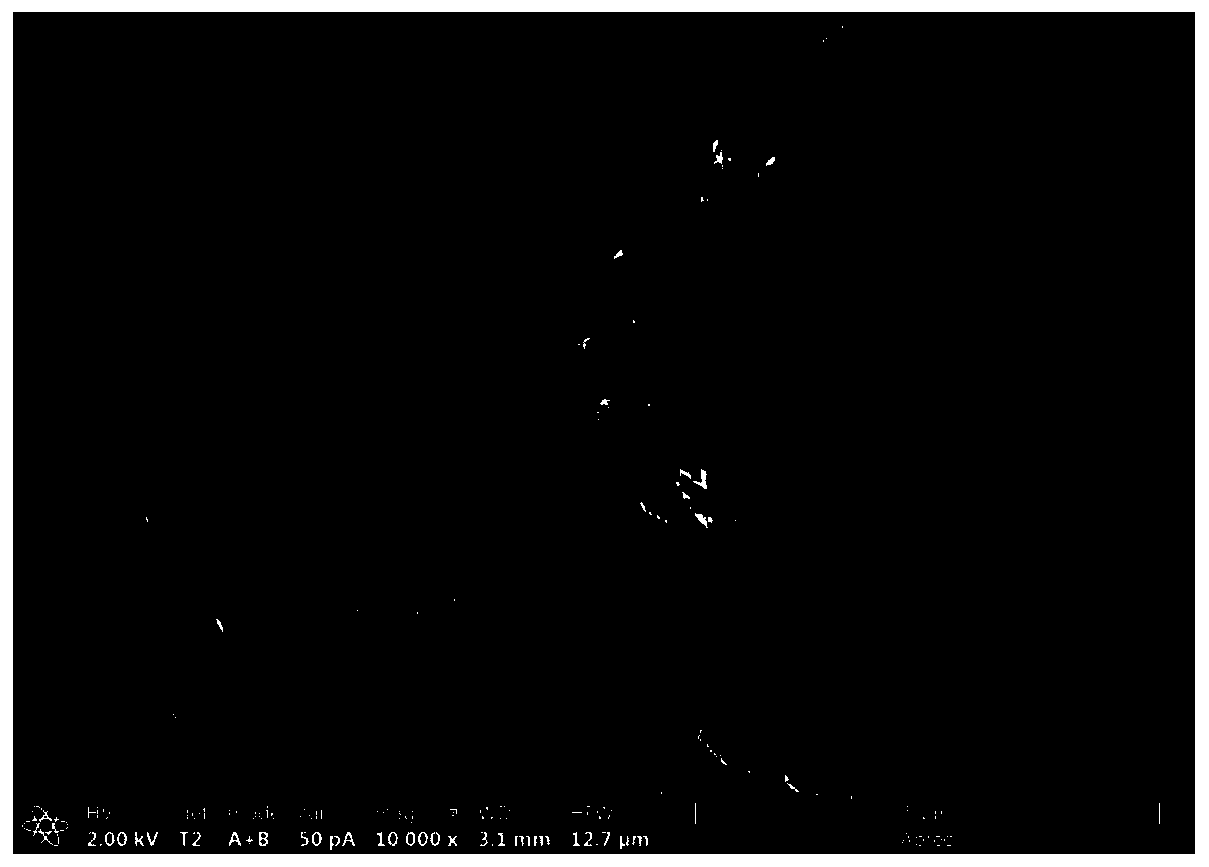

[0040] (1) Preparation of precursor solution: 0.873g (3mM) Co(NO 3 ) 2 ·6H 2 O, 0.563g (3mM) Cu(NO 3 ) 2 ·6H 2 O and 0.498 g (3 mM) 2,5-dihydroxyterephthalic acid (DTPA) were dissolved in 60 mL of a mixture of N,N-dimethylformamide (DMF) and ethanol (DMF:ethanol=1:1), The above mixed solution is stirred until completely dissolved to obtain a precursor solution;

[0041] (2) Copper-cobalt bimetallic-organic framework material based on 2,5-dihydroxyterephthalic acid ligand: transfer the precursor solution obtained in step (1) to a 100 mL polytetrafluoroethylene-lined autoclave , put the reaction kettle into a program-controlled oven, and solvothermally react at 150 °C for 24 hours; cooled, naturally cooled to room temperature, filtered with a vacuum pump, and repeated with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water. Wash to obtain brown precipitate; put the precipitate into a vacuum drying oven at 100°C for 12 hours to obtain black solid powder, whic...

Embodiment 3

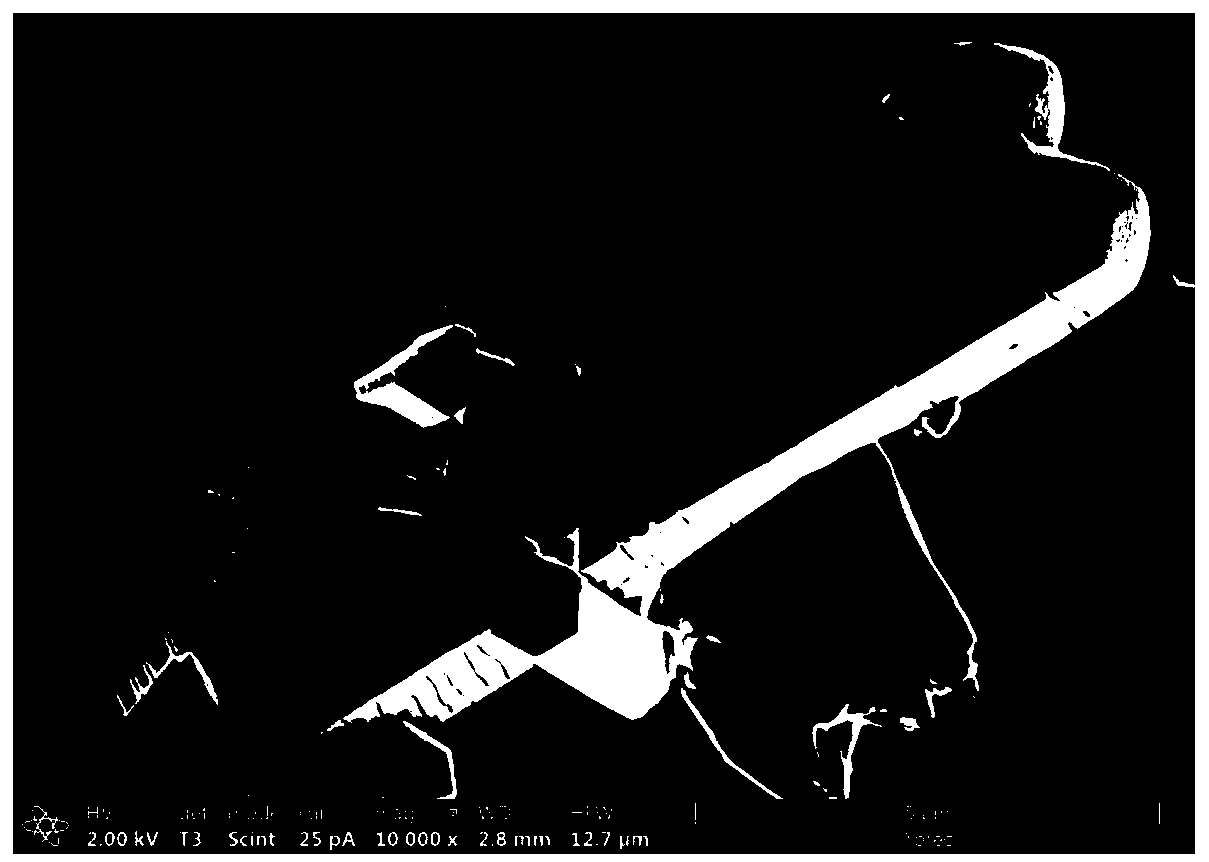

[0044] (1) Preparation of precursor solution: 0.873g (3mM) Co(NO 3 ) 2 ·6H 2 O, 0.563g (3mM) Cu(NO 3 ) 2 ·6H 2 O and 0.498 g (3 mM) 2,5-dihydroxyterephthalic acid (DTPA) were dissolved in 60 mL of a mixture of N,N-dimethylformamide (DMF) and ethanol (DMF:ethanol=1:1), The above mixed solution is stirred until completely dissolved to obtain a precursor solution;

[0045] (2) Copper-cobalt bimetallic-organic framework material based on 2,5-dihydroxyterephthalic acid ligand: transfer the precursor solution obtained in step (1) to a 100 mL polytetrafluoroethylene-lined autoclave , put the reaction kettle into a program-controlled oven, solvothermally react at 170 °C for 24 hours; cool, naturally cool to room temperature, filter with a vacuum pump and repeat with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water. Wash to obtain brown precipitate; put the precipitate into a vacuum drying oven at 100°C for 12 hours to obtain black solid powder, which is a copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com