Shape memory embedded double-layer metal grid conducting film and preparation method thereof

A double-layer metal, embedded technology, applied in the field of flexible optoelectronics, can solve problems such as fracture and device failure, and achieve the effect of good scratch resistance, excellent corrosion resistance and oxidation resistance, and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

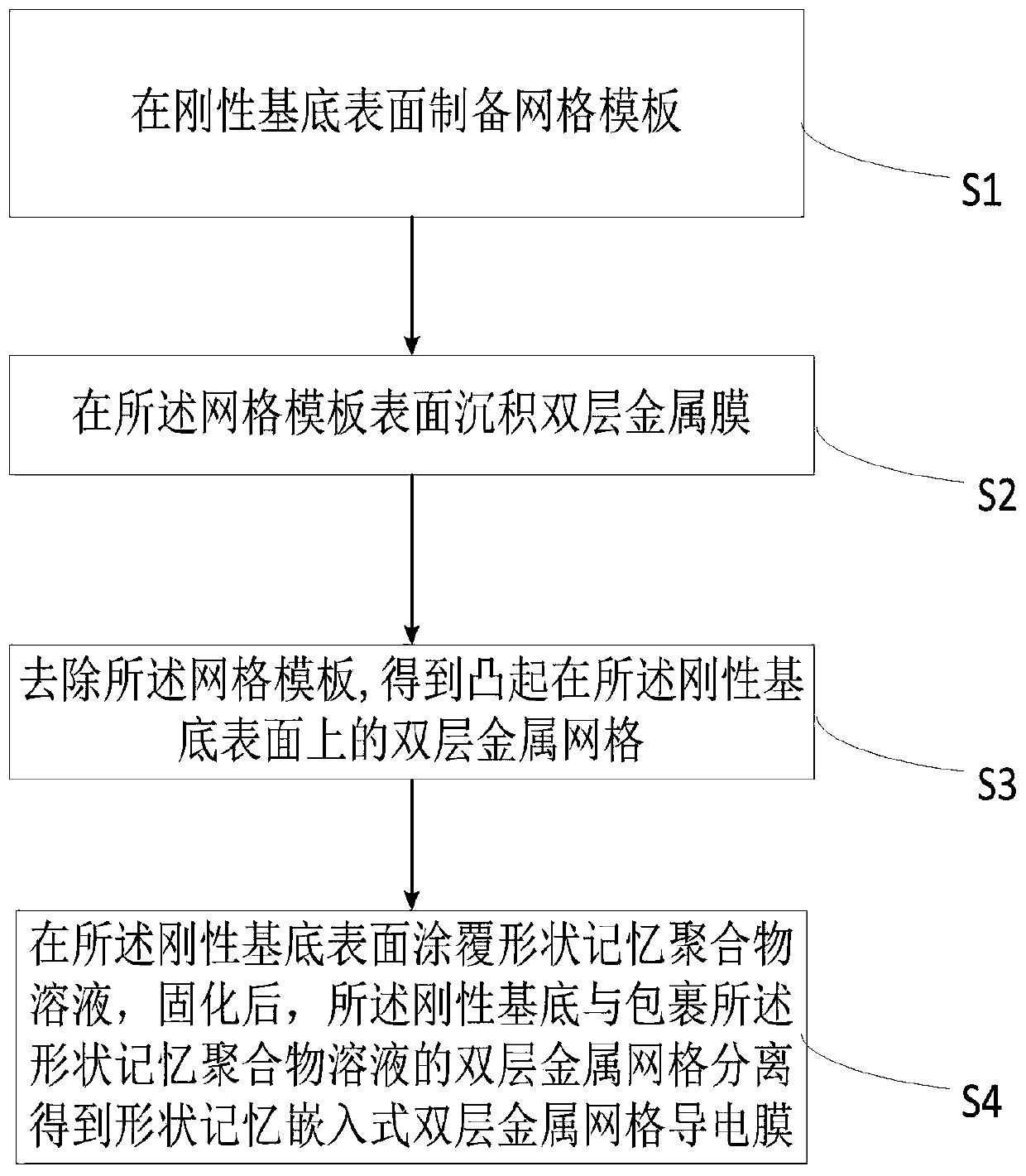

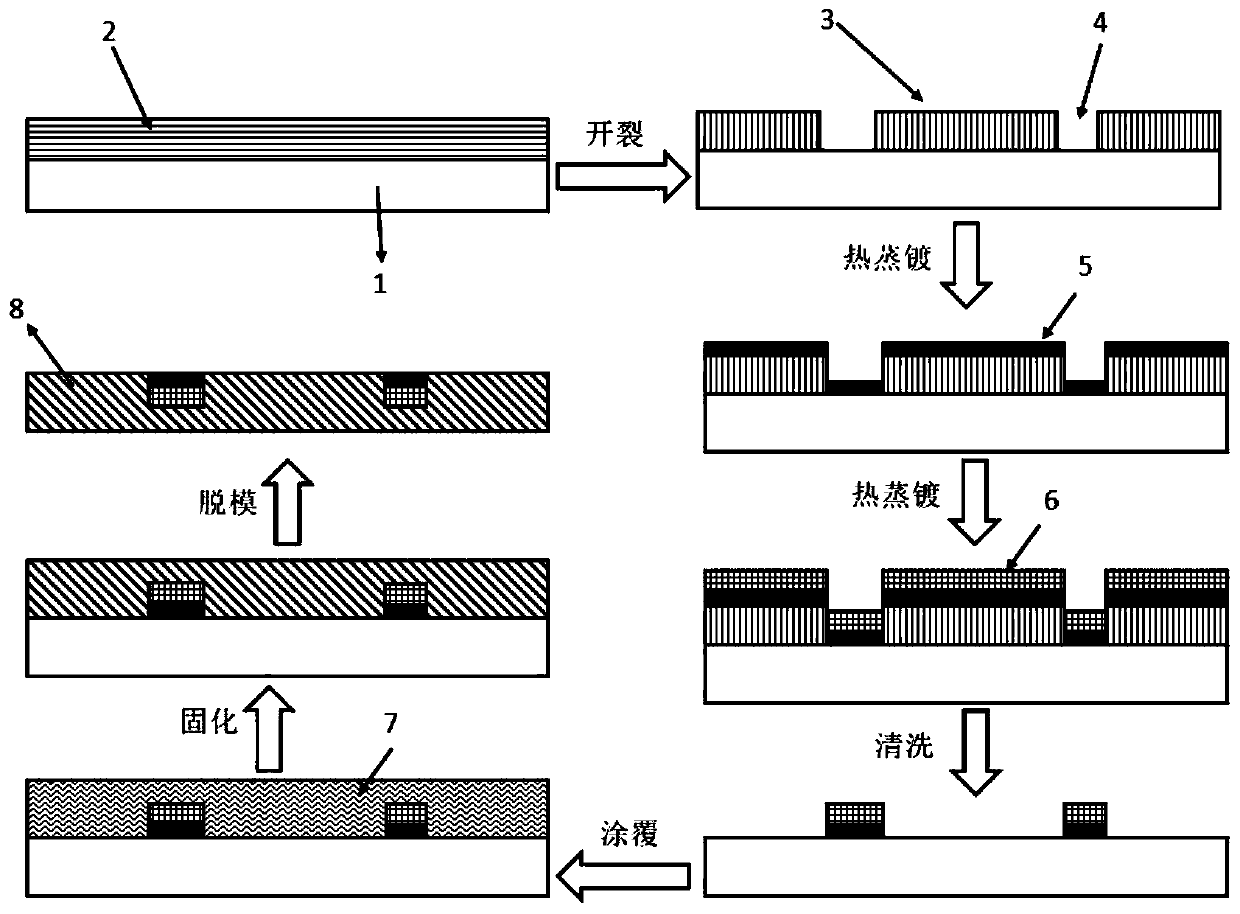

[0037] like Figure 1-3 As shown, the embodiment of the present invention provides a method for preparing a shape-memory embedded double-layer metal grid conductive film, including the following steps:

[0038] Step S1, preparing a grid template 3 on the surface of the rigid substrate 1, specifically comprising: spin-coating or spraying the polymer emulsion on the surface of the rigid substrate 1 to prepare the grid template 3;

[0039] Step S2, depositing a double-layer metal film on the surface of the grid template 3;

[0040] Step S3, removing the grid template 3 to obtain a double-layer metal grid raised on the surface of the rigid substrate 1;

[0041] Step S4, coating the shape-memory polymer 7 on the surface of the rigid substrate 1, and after curing, the rigid substrate is separated from the double-layer metal grid wrapped with the shape-memory polymer to obtain a shape-memory embedded double-layer metal mesh Lattice conductive film.

[0042] Preferably, in step S1,...

Embodiment 1

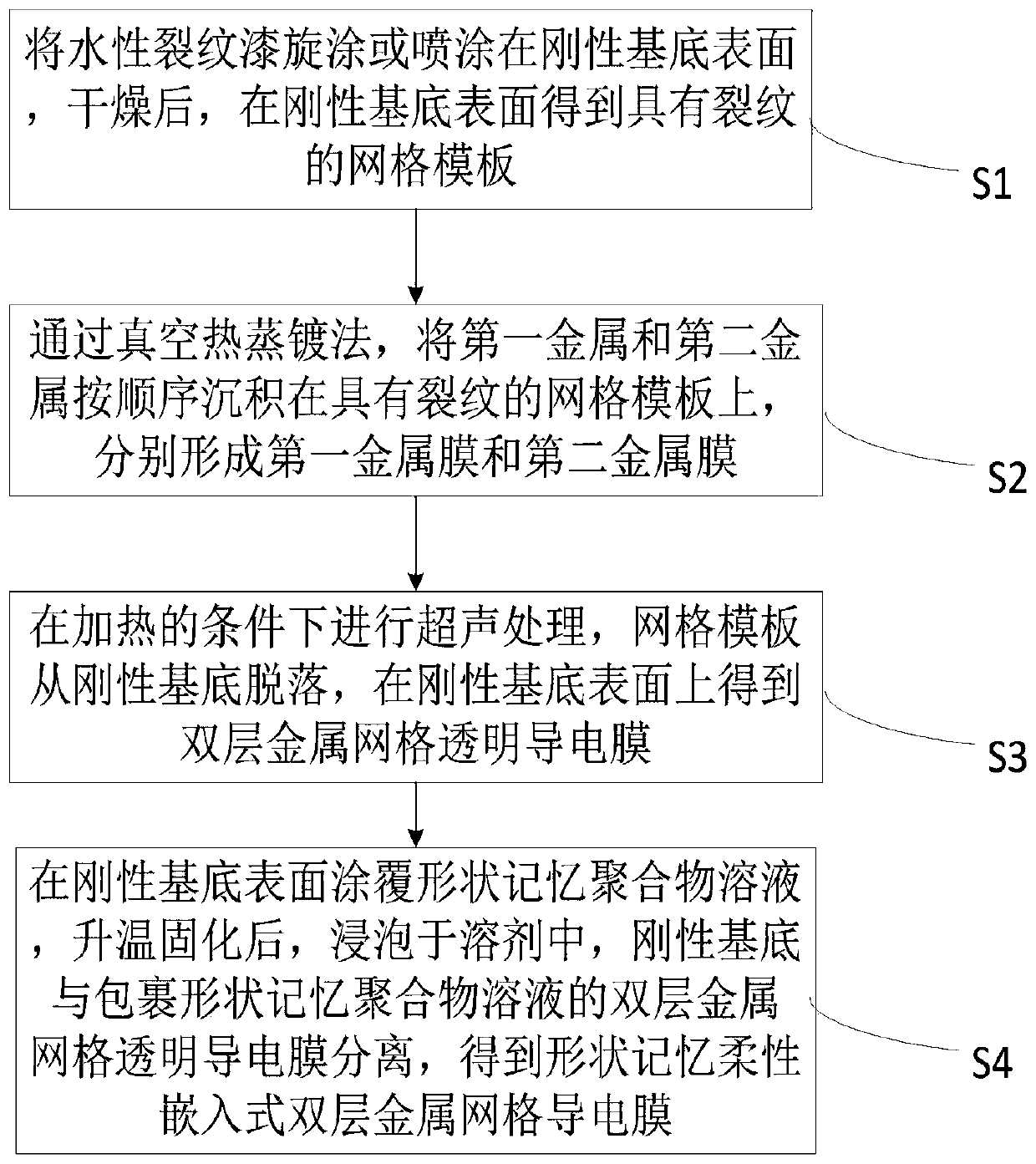

[0055] This embodiment provides a method for preparing a shape-memory embedded double-layer metal grid conductive film 8, which includes the following steps:

[0056] Step S1: preparing a grid template 3 with cracks 4;

[0057] First, prepare a water-based crackle paint emulsion with a mass fraction of 15wt%, take an appropriate amount of emulsion with a dropper and drop it on the surface of a glass sheet, prepare a layer of crackle paint 2 film by spin coating, set the speed of the glue homogenizer at 1500r / min, for 30s. The shape of the grid template 3 can be controlled by adjusting the rotational speed. The faster the rotational speed, the thinner the cracks 4 will be. On the contrary, the slower the rotational speed, the larger the width of the cracks 4 will be. Then place the glass sheet horizontally in a drying oven at 40° C. to dry for 1 min, the crack paint 2 emulsion will crack naturally, and a grid template 3 with cracks 4 will be formed on the surface of the glass ...

Embodiment 2

[0070] This embodiment provides a method for preparing a shape-memory embedded double-layer metal grid conductive film 8, which includes the following steps:

[0071] Step S1: preparing a grid template 3 with cracks 4;

[0072] First prepare a water-based crackle paint emulsion with a mass fraction of 10wt%, take an appropriate amount of emulsion with a dropper and drop it on the surface of a silicon chip, and prepare a layer of crackle paint 2 film by spin coating. 30s. The shape of the grid template 3 can be controlled by adjusting the rotational speed. The faster the rotational speed, the thinner the cracks 4 will be. On the contrary, the slower the rotational speed, the larger the width of the cracks 4 will be. Then place the silicon wafer horizontally in a drying oven at 30° C. to dry for 2 minutes, and the crack paint 2 emulsion will crack naturally, forming a layer of grid template 3 with cracks 4 on the surface of the silicon wafer.

[0073] Step S2: preparation of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com