A method and device for gas-phase magnesium purification based on nickel-based filter material

A filter material, nickel-based technology, applied in the field of gas-phase magnesium purification based on nickel-based filter material, can solve the problems of low yield of high-purity magnesium, low preparation efficiency, high cost, etc., to simplify the production process, reduce the nucleation energy barrier, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

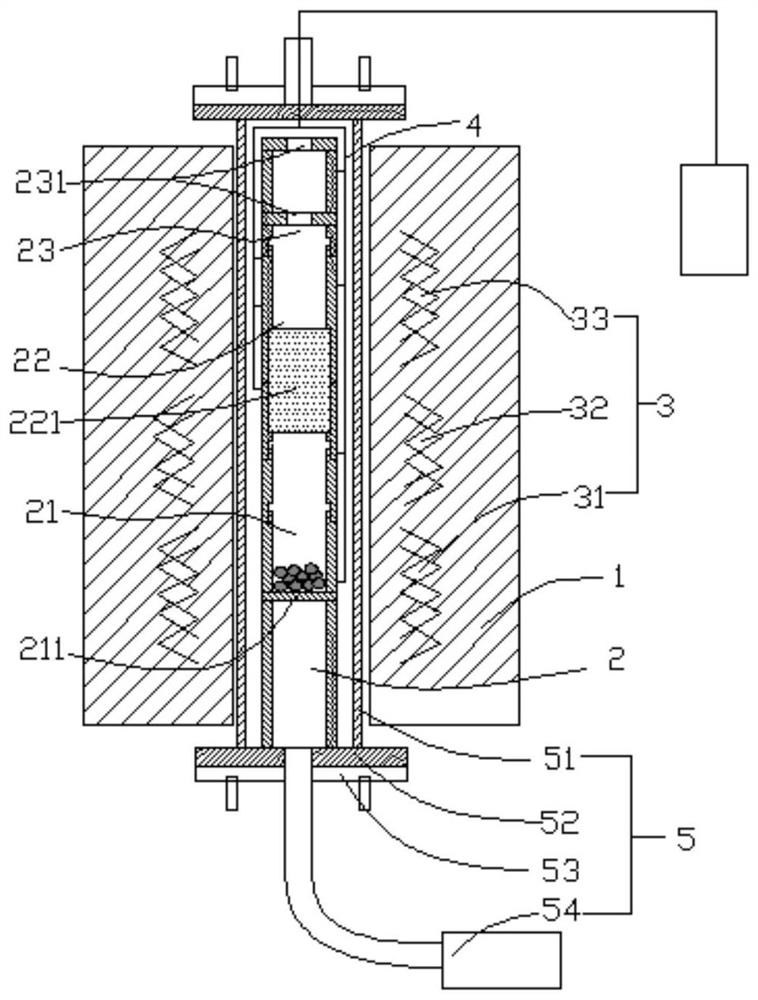

[0083] Such as figure 2 Shown, a kind of device that comprises the gas phase magnesium purification of nickel base filter material, comprises electric furnace body 1, crucible 2, heating mechanism 3, thermocouple 4 and vacuum mechanism 5;

[0084] The crucible 2 includes a reaction zone 21, an impurity condensation zone 22 and a crystallization zone 23 arranged in sequence,

[0085] The reaction zone 21 is provided with a hopper 211,

[0086] The impurity condensation area 22 is provided with a filter assembly 221,

[0087] Described filter assembly 221 is provided with filter material, and described filter material is nickel foam, and the aperture of nickel foam is 40ppi, and the purity of nickel is more than 99.5%;

[0088] The crystallization zone 23 is provided with a crystallizer 231;

[0089] The heating mechanism 3 includes a first heating assembly 31, a second heating assembly 32 and a third heating assembly 33; the first heating assembly 31 heats the reaction zone...

Embodiment 2

[0096] A kind of device that comprises the gas-phase magnesium purification of nickel base filter material, and embodiment 1 difference is that described filter assembly 221 is arranged between No. 7 and No. 8 high-purity graphite pipe fittings.

Embodiment 3

[0098] A kind of device that comprises the gas-phase magnesium purification of nickel base filter material, and embodiment 1 difference is that the pore diameter of described nickel foam is 75ppi; Described crucible is integrally formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com