Solar cell string and method for making the same

A technology for solar cells and cell sheets, applied in the field of solar cells, can solve the problems of low conductivity of conductive adhesive, resin adhesion method, low power, poor stability, etc., and achieve the effects of reducing module efficiency loss, low viscosity and tight arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

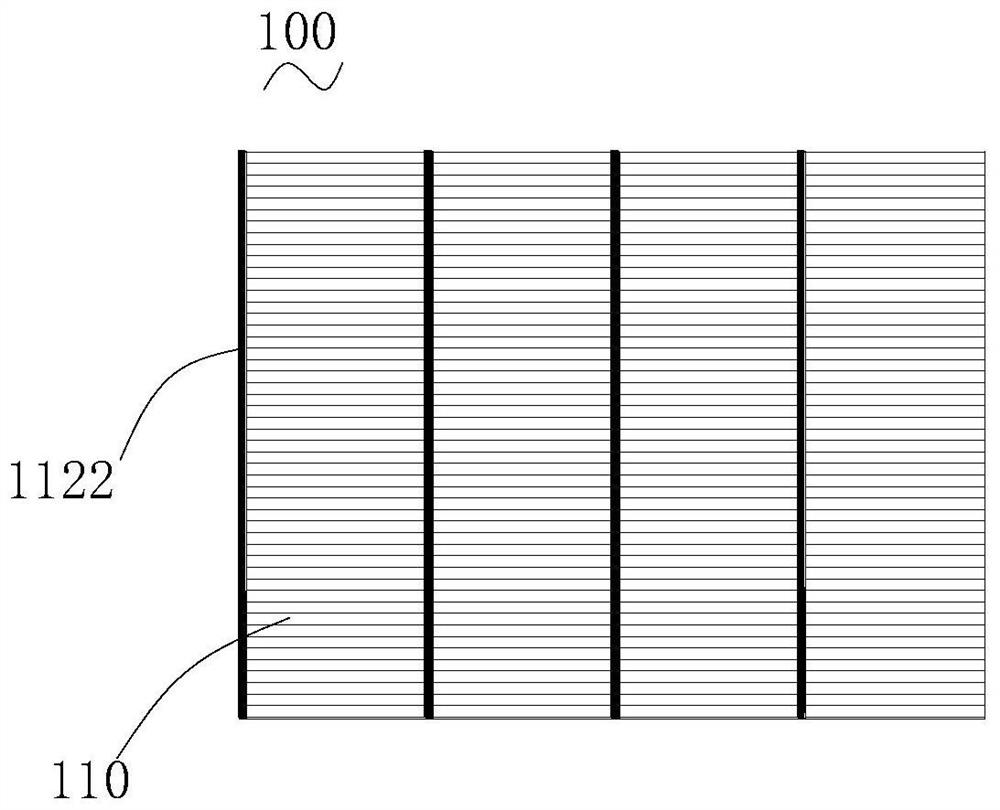

[0040] A solar battery module, two battery slices are connected in series and parallel to obtain a battery group; at least two battery groups are connected in series to obtain a solar battery module. The specific implementation is as follows: each battery pack includes 6 battery slices connected in parallel in series. Each cell series contains 17 cell units that are overlapped and connected in series through conductive paste. The cell unit is made by cutting a solar cell into 5 equal parts. The four battery packs are arranged in two rows, and each row is provided with two battery packs. When there are more battery packs, it can be arranged in multiple rows in a similar manner, and each row contains two or more battery packs.

[0041] Of course, the invention is not limited to any one form of assembly.

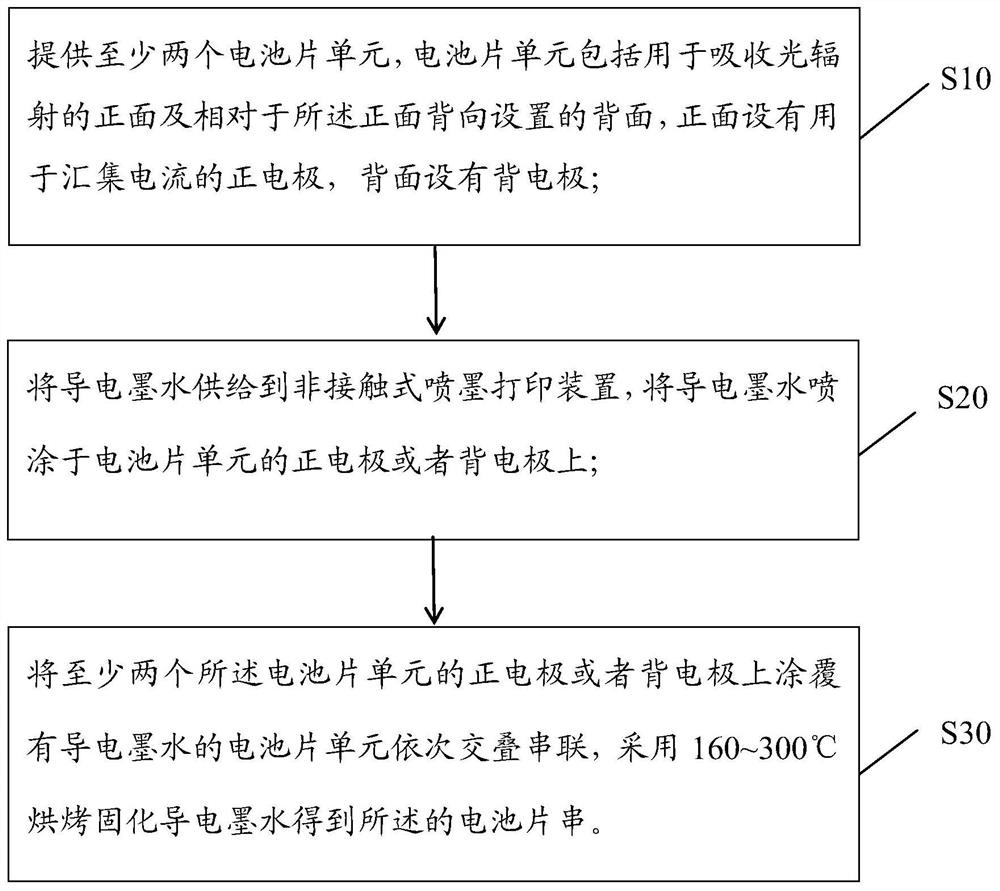

[0042] A method for preparing a solar cell string according to an embodiment, such as image 3 shown, including the following steps:

[0043] S10, providing at least two b...

Embodiment 1

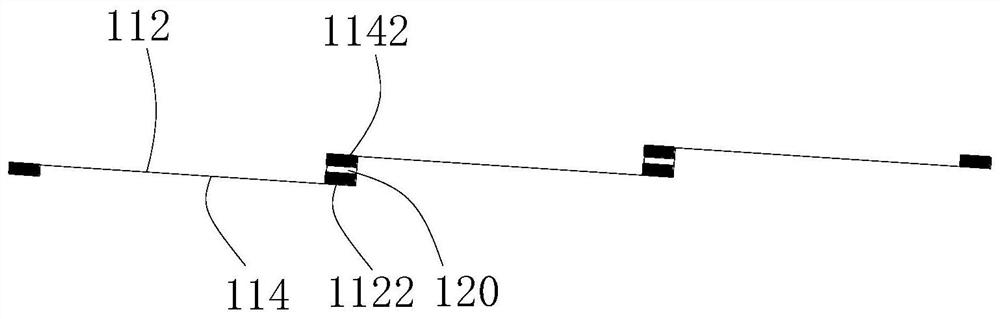

[0051] First of all, according to the design pattern, the first battery sheet unit is placed upright, and the conductive ink is supplied to the non-contact inkjet printing device. The non-contact inkjet printing device includes an inkjet printing nozzle, the nozzle and the first battery sheet unit The positive electrode of the battery cell is set in parallel, and the conductive ink forms ink droplets from the nozzles. The diameter of the ink droplet is 0.05mm. The conductive ink is sprayed on the positive electrode of the first cell unit. The viscosity of the sprayed conductive ink is 50cps, and then the second The back electrode 1142 on the back of the two cell units (located on the left side of the second cell cut sheet) overlaps and covers the positive electrode 1122 of the first cell cut sheet (located on the right side of the first cell cut sheet). Similarly, repeat the above steps, connect the back electrode 1142 (located on the left side of the third battery cutting shee...

Embodiment 2

[0054] First of all, according to the design pattern, the first battery sheet unit is placed upright, and the conductive ink is supplied to the non-contact inkjet printing device. The non-contact inkjet printing device includes an inkjet printing nozzle, the nozzle and the first battery sheet unit The positive electrode of the battery cell is set in parallel, and the conductive ink forms an ink drop from the nozzle hole. The diameter of the ink drop is 0.1mm. The conductive ink is sprayed on the positive electrode of the first cell unit. The viscosity of the sprayed conductive ink is 100cps, and then the second The back electrode 1142 on the back of the two cell units (located on the left side of the second cell cut sheet) overlaps and covers the positive electrode 1122 of the first cell cut sheet (located on the right side of the first cell cut sheet). Similarly, repeat the above steps, connect the back electrode 1142 (located on the left side of the third battery cutting shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com