Semiconductor device based on composite substrate and preparation method thereof

A composite substrate and semiconductor technology, applied in the field of microelectronics, can solve problems affecting the quality of semiconductor devices, low thermal conductivity of Si substrates, slow heat dissipation of semiconductor devices, etc., to avoid device failure, improve heat dissipation efficiency, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] See figure 1 , figure 1 It is a schematic flowchart of a method for manufacturing a semiconductor device based on a composite substrate provided by an embodiment of the present invention. An embodiment of the present invention provides a method for preparing a semiconductor device based on a composite substrate, the method comprising the following steps:

[0037] Step 1. Select the Si substrate layer.

[0038] Step 2, growing a diamond layer on the lower surface of the Si substrate layer.

[0039] See Figure 2a , Figure 2a A flow chart of a manufacturing process of a semiconductor device based on a composite substrate provided by an embodiment of the present invention. Specifically, a diamond layer with a thickness of 30-200 μm is grown on the lower surface of the Si substrate layer by using Microwave Plasma Chemical Vapor Deposition (MPCVD for short). The process conditions are as follows: the gas used in the reaction chamber of the microwave plasma chemical va...

Embodiment 2

[0057] see again Figure 2a-2d , the present invention introduces the specific preparation methods of the embodiments of the present invention on the basis of the above-mentioned embodiments. The preparation method of the embodiment of the present invention comprises the following steps:

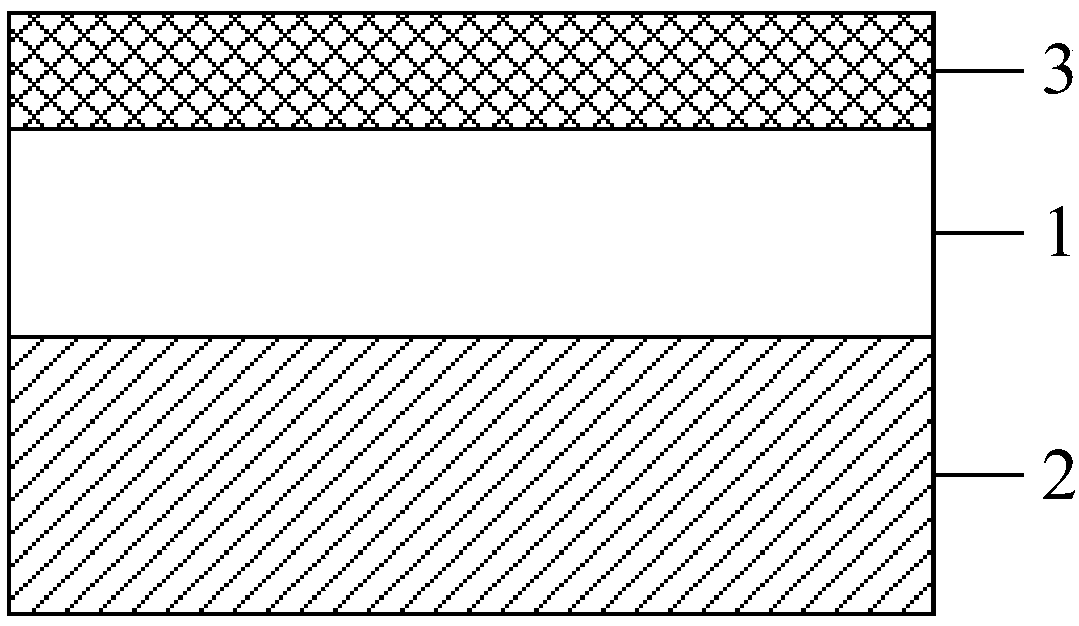

[0058] S1. Select the Si substrate layer 1 .

[0059] Preferably, the Si substrate layer 1 with a thickness of 1.5 mm is selected as the initial material.

[0060] S2 , growing a diamond layer 2 on the lower surface of the Si substrate layer 1 .

[0061] see again Figure 2a , using a chemical vapor deposition method to grow a diamond layer 2 on the lower surface of the Si substrate layer 1;

[0062] Specifically, a diamond layer 2 with a thickness of 30 μm was grown on the lower surface of the Si substrate layer 1 by MPCVD. The process conditions are as follows: the gas in the MPCVD reaction chamber is a mixed gas of methane and hydrogen, the total flow rate of the mixed gas is 200 scc...

Embodiment 3

[0081] see again Figure 2a-2d , the present invention introduces the specific preparation methods of the embodiments of the present invention on the basis of the above-mentioned embodiments. The preparation method of the embodiment of the present invention comprises the following steps:

[0082] S1. Select the Si substrate layer 1 .

[0083] Preferably, the Si substrate layer 1 with a thickness of 1.5 mm is selected as the initial material.

[0084] S2 , growing a diamond layer 2 on the lower surface of the Si substrate layer 1 .

[0085] See you again Figure 2a , using a chemical vapor deposition method to grow a diamond layer 2 on the lower surface of the Si substrate layer 1;

[0086] Specifically, a diamond layer 2 with a thickness of 200 μm was grown on the lower surface of the Si substrate layer 1 by MPCVD. The process conditions are as follows: the gas in the MPCVD reaction chamber is a mixed gas of methane and hydrogen, the total flow rate of the mixed gas is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com