In-vehicle high-voltage cable of new energy electric vehicle and preparation method thereof

A technology of electric vehicles and internal high voltage, which is applied in the direction of power cables, cable/conductor manufacturing, and power cables with shielding layers/conductive layers, etc. It can solve problems such as poor flexibility and bending performance, heavy weight of the cable body, and low temperature resistance. Achieve the effect of meeting long-term bending use, reducing weight and reducing cable weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

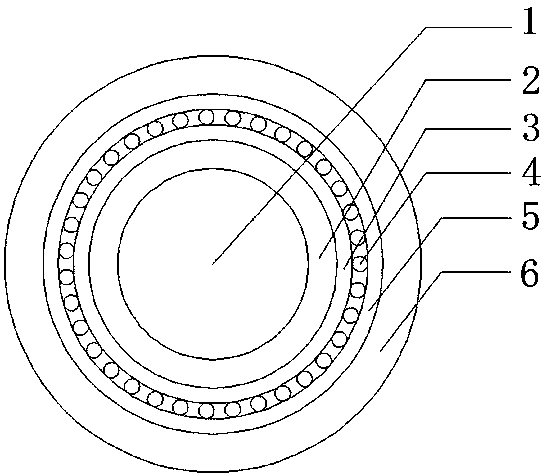

[0024] Such as figure 1 As shown, a new energy electric vehicle high-voltage cable includes a conductor arranged inside the cable. The conductor 1 is made of multi-layer strands twisted together, and the strands are bundled by multiple tinned copper wires. , the beam direction is opposite to the re-twisting direction of the strands, and the beam pitch ratio is controlled within 20-25 times;

[0025] The conductor is extruded with a high-temperature-resistant 180°C high-tear-resistant mixed silicone rubber insulating layer 2, and the high-temperature-resistant 180°C high-tear-resistant mixed silicone rubber insulating layer is wrapped with the first high-temperature-resistant insulating layer 3. The shielding layer 4 that can also be used as the negative electrode core is wound outside the high-temperature-resistant insulating layer in a loose winding manner, and the second high-temperature-resistant insulating layer 5 is wrapped around the outer shielding layer, and the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com