A Ti-based PBO based on in situ thermal reaction to prepare the intermediate layer of conductive ceramic film 2 Anode preparation method

A conductive ceramic and intermediate layer technology, applied in the direction of surface reaction electrolytic coating, electrolytic inorganic material coating, coating, etc., can solve the problems of high energy consumption and poor durability, and achieve high electrocatalytic activity, long service life, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

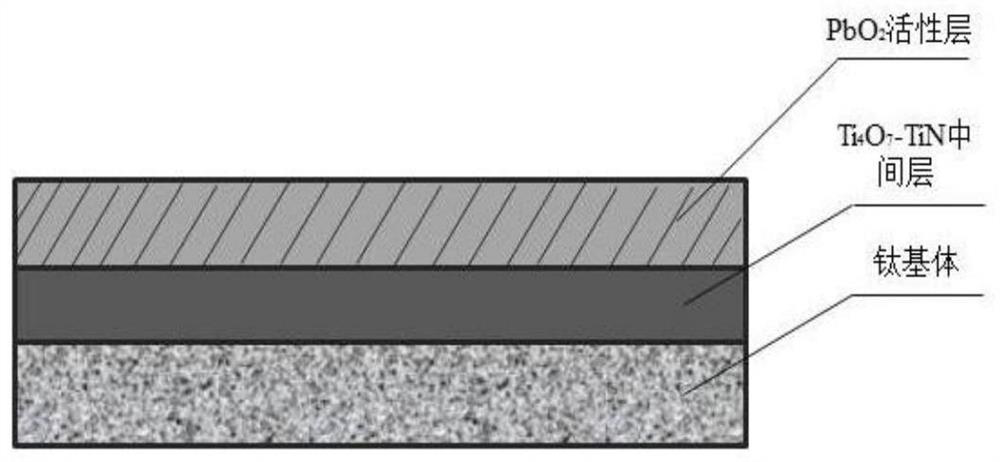

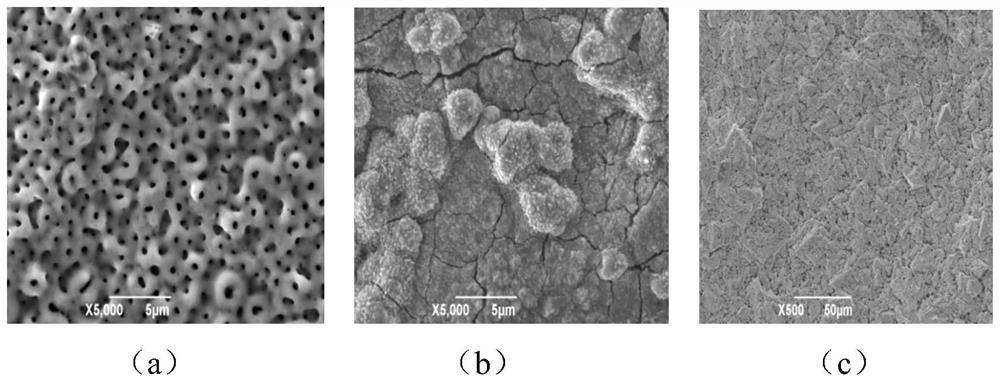

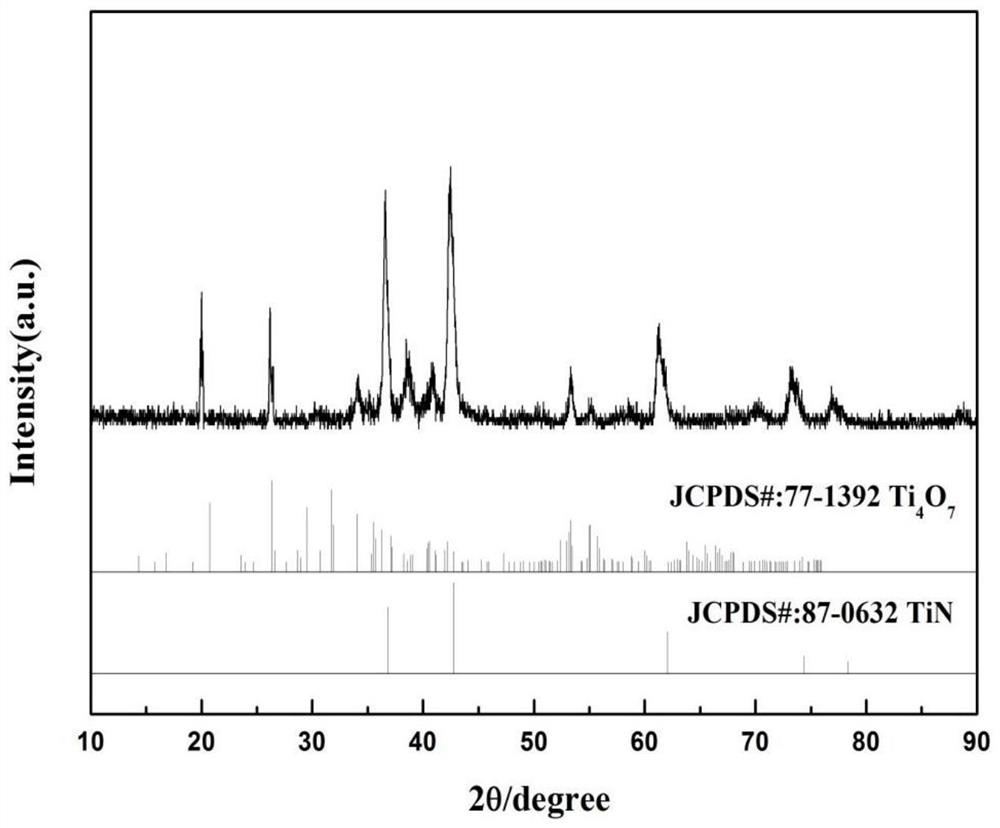

[0022] First use after 80 # , 160 # 、240 # 、400 # Water sandpaper is continuously mechanically polished to make the titanium substrate bright, and then degreasing-water washing-pickling-water washing-anodizing-water washing is carried out, and the titanium-based titanium oxide film is grown in situ by anodic oxidation (surface morphology see figure 2 (a)). Then the titanium oxide film attached to the titanium material is reduced in situ under a high-temperature hydrogen atmosphere to form a Ti with good conductivity. 4 o 7 -TiN conductive ceramic intermediate layer (see surface morphology figure 2 (b)), finally with Ti / Ti 4 o 7 -TiN electrode material is used as anode, stainless steel with equal area is used as cathode, and β-PbO is produced by electrooxidation of anode 2 active layer, thus preparing Ti / Ti 4 o 7 -TiN / PbO 2 anode. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com