Large-area thin-layer high-quality black phosphorus nano-sheet and electrochemical stripping preparation method thereof

A high-quality, large-area technology, applied in chemical instruments and methods, preparation of phosphorus, phosphorus compounds, etc., can solve the problems of small size of few-layer black phosphorus nanosheets, not satisfying larger sizes, and residues on the surface of the sheet, etc. Achieve high stripping efficiency, maintain integrity and size, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] An aspect of the embodiments of the present invention provides a method for preparing large-area thin-layer high-quality black phosphorus nanosheets by electrochemical stripping, which includes:

[0029] Use black phosphorus as the working electrode, and at least construct an electrochemical reaction system together with the counter electrode and the electrolyte, wherein the electrolyte contains tetrabutylammonium ions (TBA + ) in acetonitrile;

[0030] The working electrode and the counter electrode are electrically connected to the negative pole and the positive pole of the power supply respectively, so that a selected voltage is applied between the working electrode and the counter electrode, and then peeled off from the black phosphorus to obtain a large-area thin layer of high-quality black phosphorus. Phosphorus nanosheets.

[0031] In some preferred solutions, the concentration of the acetonitrile solution containing tetrabutylammonium ions during the electroche...

Embodiment 1

[0057] Example 1 Electrochemical exfoliation of bulk BP crystals

[0058] Such as figure 1 As shown in the schematic diagram of the electrochemical stripping black phosphorus device in China, select a BP block with a size of cubic centimeters, wrap it with platinum wire and clamp it on the platinum electrode clip as the working electrode, and use a pure platinum electrode parallel to the working electrode as the counter electrode at the other end , the distance between the two electrodes can be adjusted according to the required voltage, and the distance is 1-2 cm, preferably 1.5 cm. First, prepare 0.5-2mol / L (preferably 1mol / L) acetonitrile solution of tetrabutylammonium bisulfate, soak the electrode and the block into the solution respectively, and connect the current flowing from the negative electrode of the workstation to the electrode connected to the BP block superior. After the black phosphorus block is completely soaked in the electrolyte, apply a voltage of 10V to ...

Embodiment 2

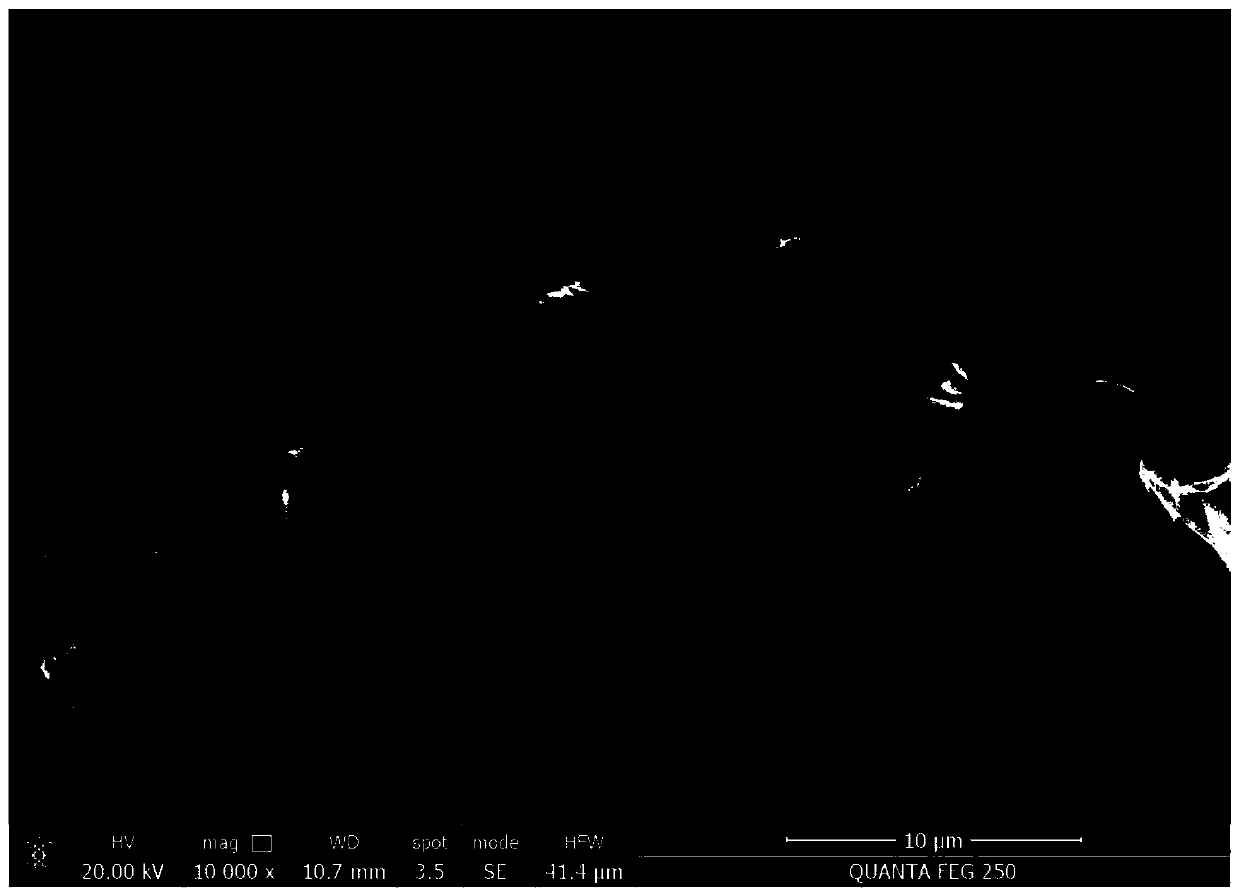

[0061] This example is basically the same as Example 1, except that tetrabutylammonium bisulfate is replaced by n-butylammonium tetrafluorophosphate. After testing, please refer to the SEM image of the black phosphorus nanosheets obtained in this embodiment image 3 .

[0062] It can be seen from Examples 1-2 that the innovation of the present invention lies in the discovery that the electrochemical stripping effect of the two-dimensional material is related to whether the ionic radius of the electrolyte in the electrolyte matches the interlayer distance of the two-dimensional material. In the process of stripping black phosphorus, the synergistic effect of n-butylammonium ion and acetonitrile is used. The influence of n-butyl ammonium ion on the stripping process, that is, high-efficiency and large-area stripping, and the influence of acetonitrile on the stripping effect, that is, the cleanliness of the sheet obtained by stripping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com