Graphite phase carbon nitride catalyst preparation method

A graphite-phase carbon nitride and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex process, high cost, difficult large-scale preparation, etc., and achieve simple operation , low cost, and the effect of improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

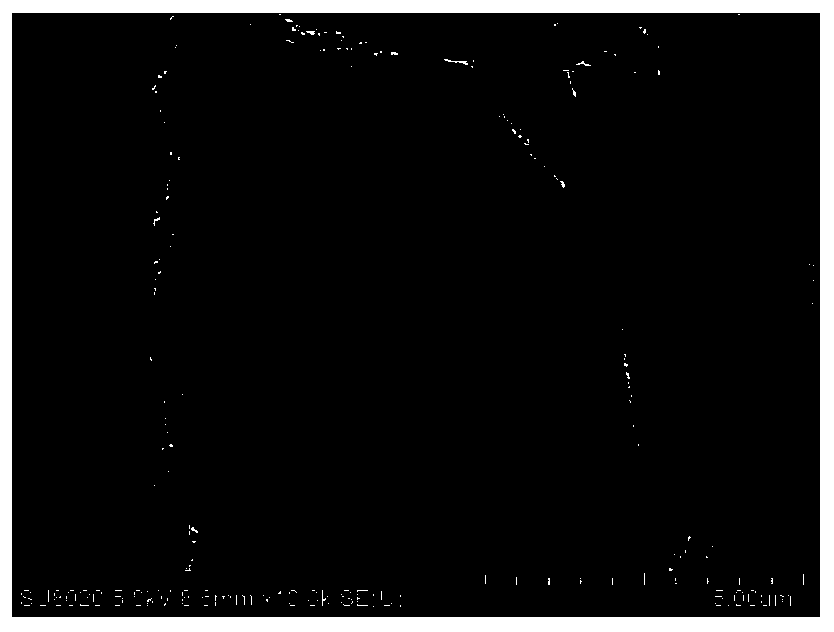

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention provides a preparation method of graphite phase carbon nitride, which comprises the following steps:

[0021] (1) Add the precursor and biomass into water according to a certain ratio, stir magnetically, and heat to 80°C until the water evaporates to dryness to obtain a mixture.

[0022] (2) Put the mixture obtained in step (1) into a quartz crucible, seal it with aluminum foil, heat it to 500°C-600°C under a nitrogen atmosphere, and continue the reaction for 2-24h to obtain a graphite phase carbon nitride catalyst.

[0023] In the present invention, the biomass material has elements such as C, N, and H, and can be better combined with the precursor to increase the nitrogen content on the surface of the carbon nitride, and at the same time, it is easy to remove after calcination without affecting the crystal structure of the catalyst.

[0024] Specifically, the biomass refers to: directly derived from organisms or extracts from or...

Embodiment 1

[0038] Preparation of graphitic carbon nitride catalyst:

[0039] (1) Weigh 10g of urea and 0.006g of chitin into a 250mL beaker, add 100mL of water, ultrasonicate for 60min, and heat to 80°C with magnetic stirring until the water is evaporated to dryness to obtain a mixture.

[0040] (2) Put the mixture obtained in step (1) into a quartz crucible, seal it with aluminum foil, heat it to 550°C at a heating rate of 10°C / min under a nitrogen atmosphere, and continue the reaction for 2h to obtain a light yellow graphite phase carbon nitride catalyst .

Embodiment 2

[0042] Preparation of graphitic carbon nitride catalyst:

[0043] (1) Weigh 10g of urea and 0.006g of lignin into a 250mL beaker, add 100mL of water, ultrasonicate for 60min, heat to 80°C with magnetic stirring, until the water is evaporated to dryness, to obtain a mixture.

[0044] (2) Put the mixture obtained in step (1) into a quartz crucible, seal it with aluminum foil, heat it to 550°C at a heating rate of 10°C / min under a nitrogen atmosphere, and continue the reaction for 2h to obtain a yellow graphite phase carbon nitride catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com