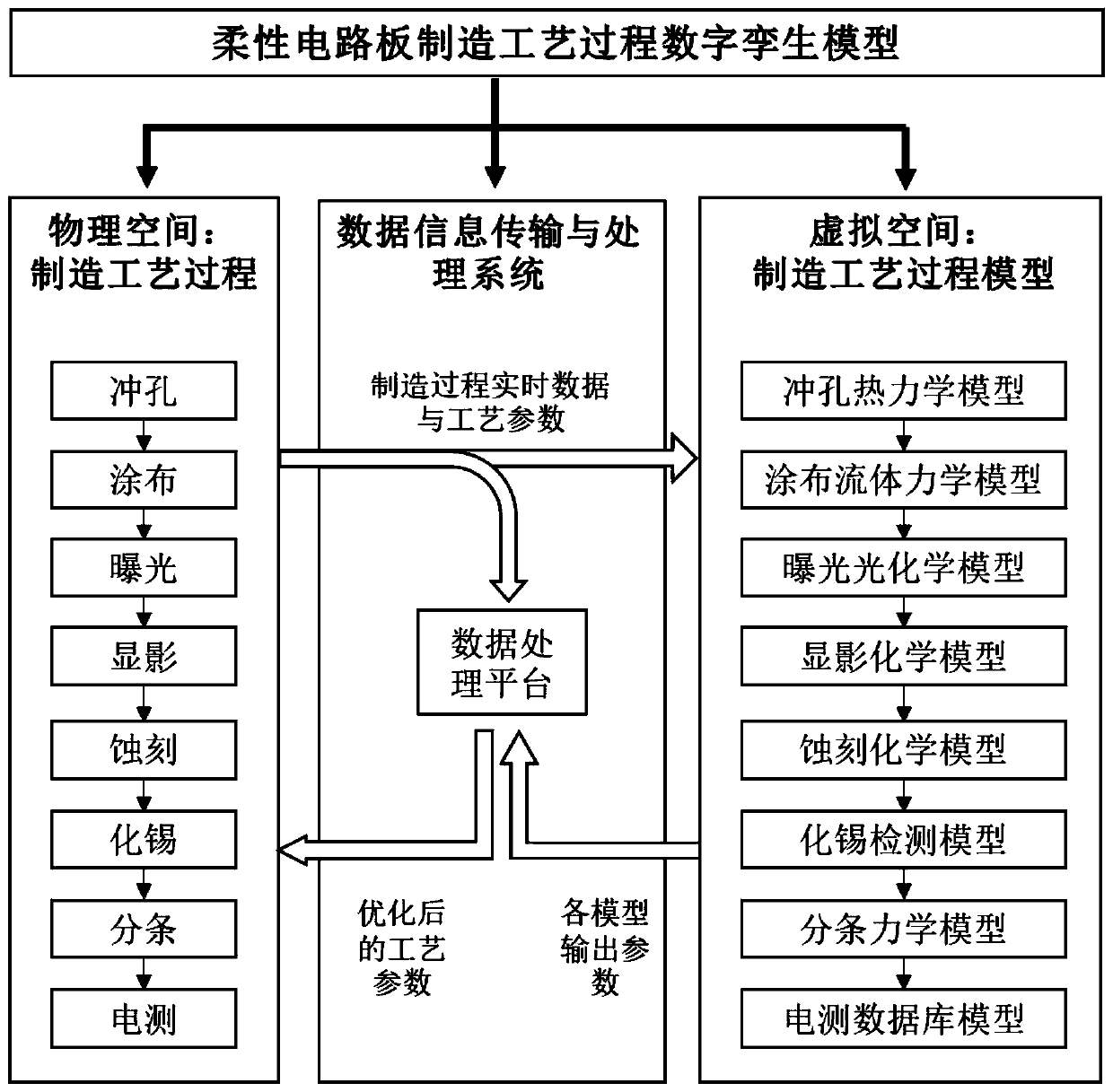

Digital twinning model for manufacturing process of flexible circuit board

A flexible circuit board and manufacturing process technology, which is applied in CAD circuit design, CAD numerical modeling, design optimization/simulation, etc., can solve problems such as implementation prediction exceptions, and achieve the goals of reducing production costs, improving production efficiency, and increasing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0032] An embodiment of the present invention provides a digital twin model for a flexible circuit board manufacturing process.

[0033] In the punching process, the coordinate information of the drill bit, the chip shape image information, the drilling force and the drilling temperature are monitored and collected, and the data are transmitted to the thermodynamic model and data processing platform of the punching process.

[0034] Establish the punching process thermodynamic model corresponding to the physical space punching process in the virtual space, construct the finite element solid model of the punching process, and establish the heat conduction control equation according to the Fourier heat transfer law and the law of energy conservation to punch holes The information collected by the process is used as the simulation input. Based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com