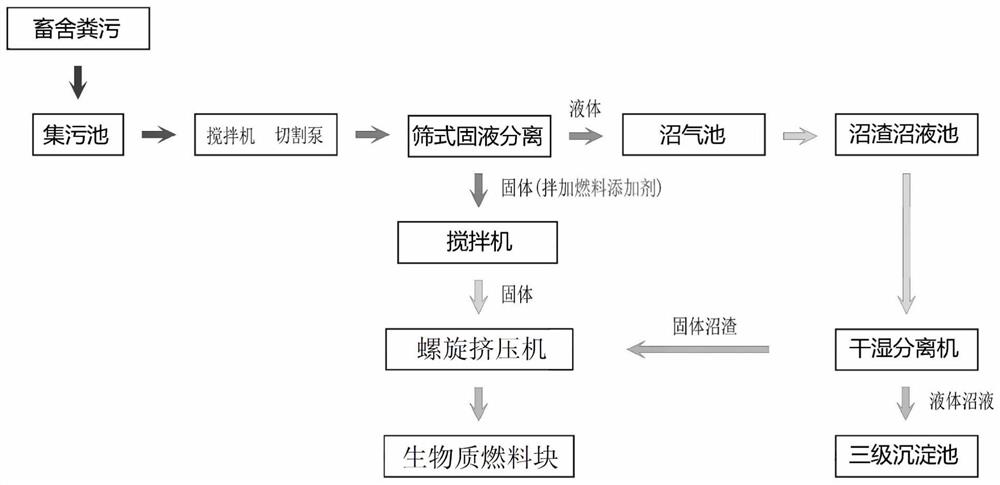

Preparation method of biomass briquette fuel pressed from pig manure

A molding fuel and pig manure technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of extremely high moisture content of pig manure, equipment investment, energy consumption, solid fuel molding and granulation, etc., to save power input , save equipment investment, and promote the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

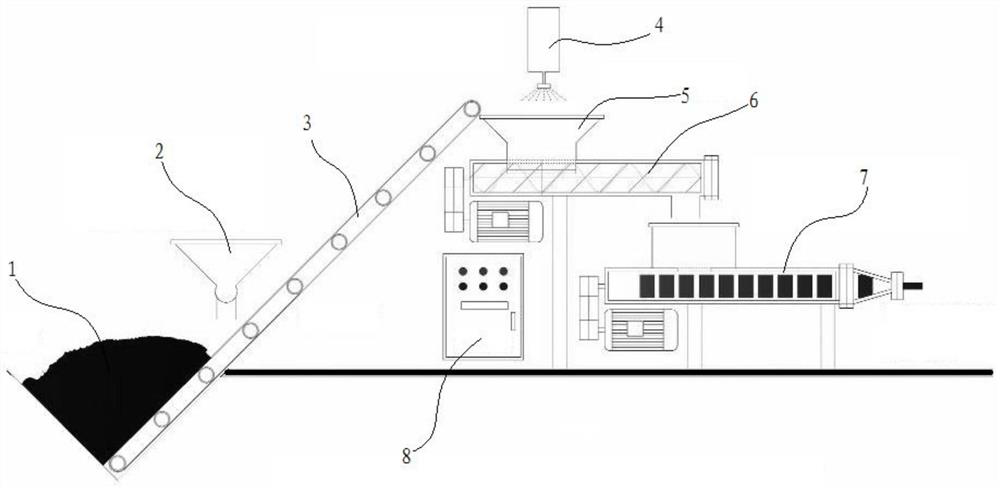

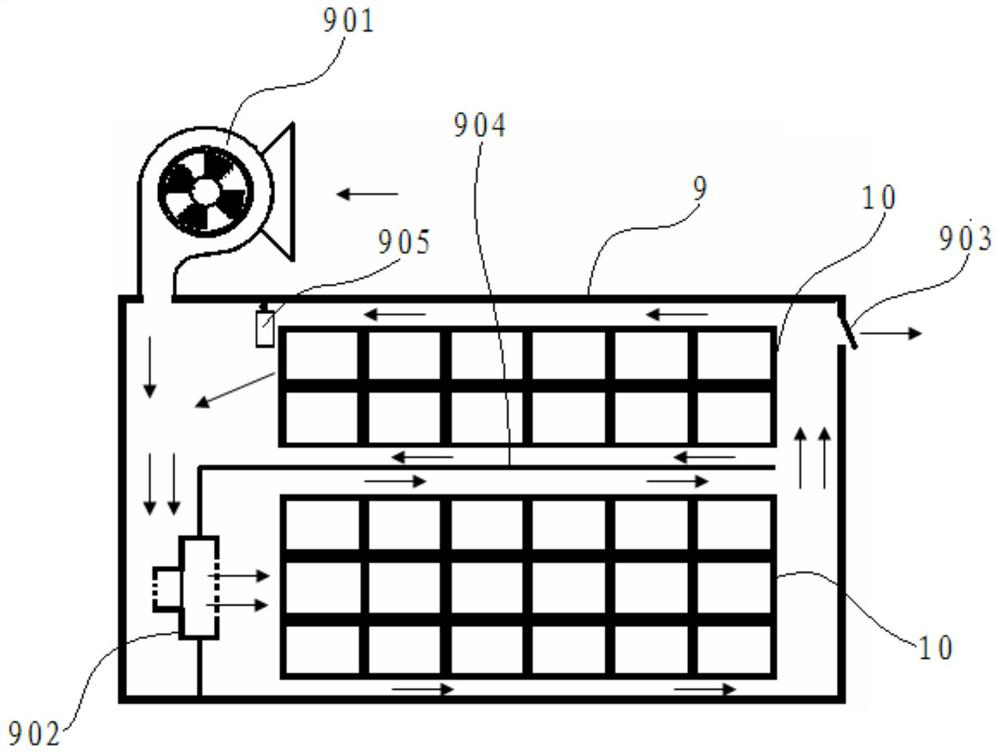

[0044] Embodiment 1: Referring to the accompanying drawings, reflecting a specific structure of the present invention, the preparation system of the biomass briquette fuel pressed by pig manure is composed of an upper feeding bin 1, an auxiliary material adding bin 2 and its unloading auger, and a conveyor belt 3. Strain sprayer 4, mixer 6, screw extruder 7 (such as 140-type coal rod machine), cutting machine and control box system 8 form a continuous production line, and the feeding bin 1 is connected by a conveyor belt 3 The feeding port 5 of the mixer 6, the conveyor belt 2 between the feeding bin 1 and the mixer 6 is connected to the auxiliary material adding bin 2 through the feeding auger, the feeding port 5 of the blender 6 is provided with a strain sprayer 4, and the blender 6 The discharge port of the screw extruder 7 is connected to the feed port of the screw extruder 7, and the discharge port of the screw extruder 7 is provided with a cutting machine (not shown in th...

Embodiment 2

[0059] Embodiment 2: the difference with embodiment 1 is:

[0060] ① In the preparation stage, take the dried pig manure residue fermented in the organic fertilizer fermentation bed of the pig farm, with a moisture content of 21%;

[0061] The ratio is: 78 parts of pig manure residue, 15 parts of coal powder, 1.5 parts of sodium carboxymethyl starch, 2 parts of potassium chlorate, 2 parts of decoking agent, 0.5 parts of smoke suppressant, 4 parts of industrial salt, pig manure fermentation biological bacteria Seed (aqua) 1 part.

[0062] The moisture content of the pretreated mixture is 20%.

[0063] ② Moisture content of molded body is 20%.

[0064] ③ The moisture content of the finished biomass fuel block is 14%. The total time spent is 1 day.

[0065] The biomass fuel blocks produced in this embodiment are hexagonal hollow columns with a diameter of 38 mm, a hollow diameter of 12 mm, and a length of 5 cm. The density is 1290kg / m 3 . No smell. The combustion is compl...

Embodiment 3

[0066] Embodiment 3: the difference with embodiment 1 is:

[0067] ① In the preparation stage, dry manure method is used to collect fresh pig manure residue in the pig farm house, with a moisture content of 65%;

[0068] The ratio is: 75 parts of pig manure residue, 13 parts of coal powder, 1 part of sodium carboxymethyl starch, 3 parts of potassium chlorate, 2 parts of decoking agent, 1 part of smoke suppressant, 6 parts of industrial salt, and pig manure fermenting biological bacteria Plant 1 part.

[0069] The moisture content of the pretreated mixture was 58%.

[0070] ②Moisture content of molded body is 58%.

[0071] ③The room temperature in the insulation room is 28°C. After the fuel block was put in for 34 hours, the maximum temperature of the fuel block reached 70°C. The moisture content of the finished biomass fuel block is 16%. The total time spent is 4 days.

[0072] The biomass fuel blocks produced in this embodiment are hexagonal hollow columns with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com