Liquid fuel catalytic reforming device

A technology for catalytic reforming and liquid fuel, applied in inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve problems such as large temperature gradient, carrier cracking, limiting the overall performance of liquid fuel reforming device, etc., to improve efficiency , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

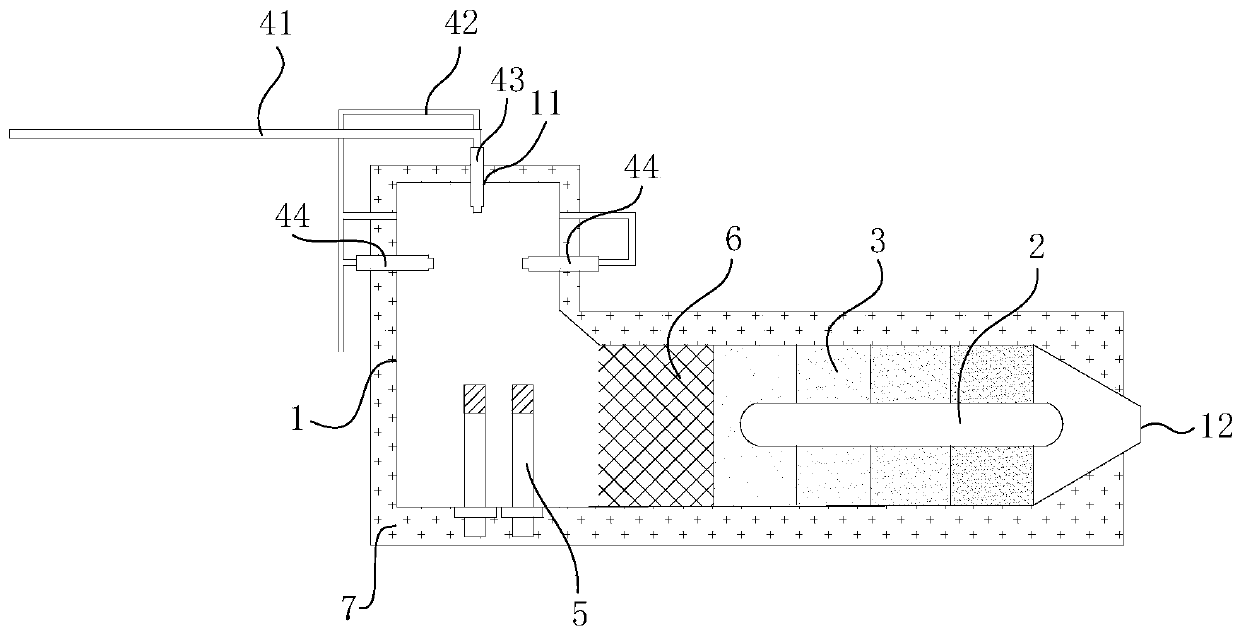

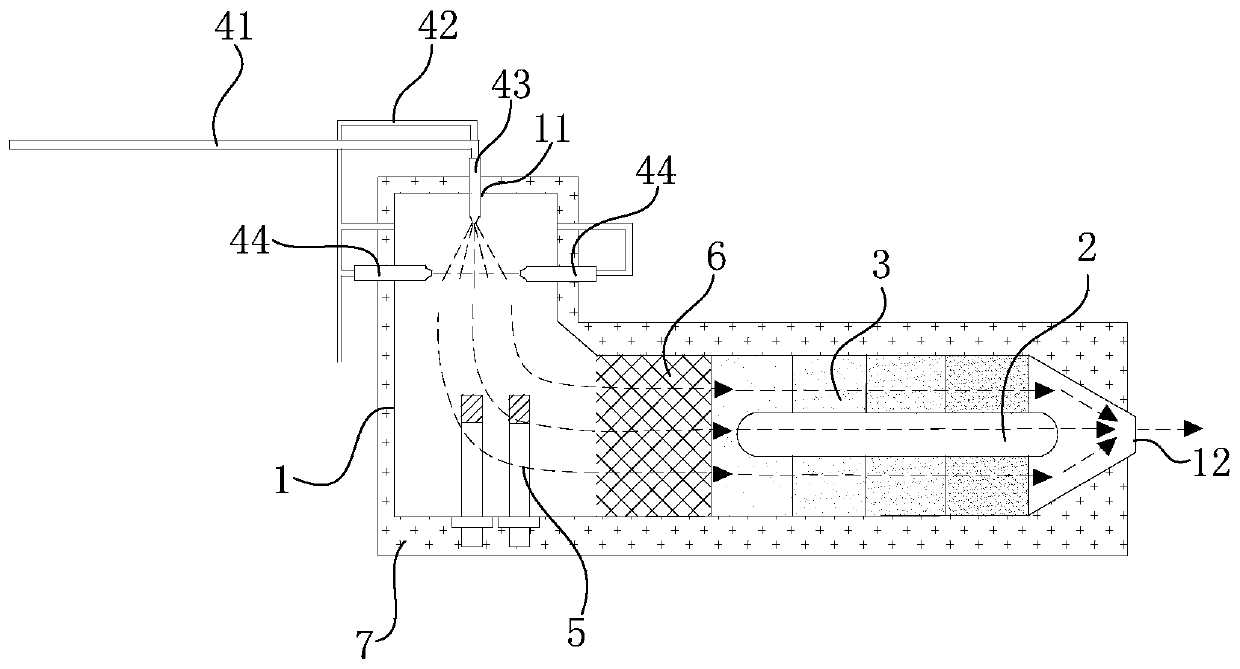

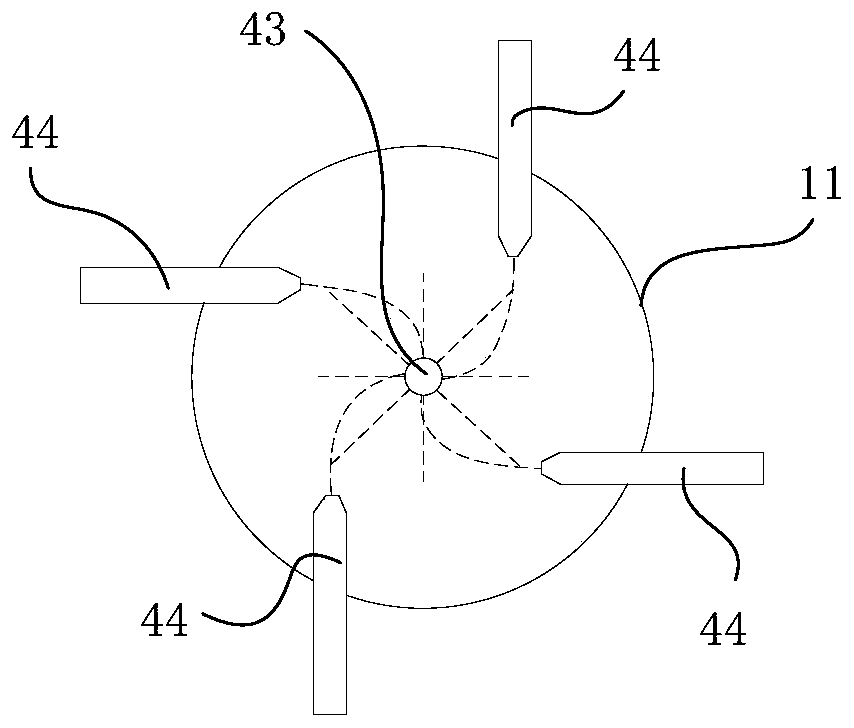

[0041] refer to figure 1 , figure 2 and image 3 , this embodiment provides a liquid fuel catalytic reforming device, the liquid fuel catalytic reforming device includes a housing 1 and a high-temperature heat pipe 2; a reaction chamber is provided inside the housing 1, and the inside of the reaction chamber includes a catalytic reforming area, the catalytic reforming area is used to fill the catalyst 3; on the housing 1, the two ends of the catalytic reforming area are respectively provided with a reaction chamber inlet 11 and a reaction chamber outlet 12; the high temperature heat pipe 2 is configured to be able to be assembled in the catalytic reforming area The inside of the region is used to balance the temperature of the catalyst 3 filled in the catalytic reforming region along the direction of fluid flow from the reaction chamber inlet 11 to the reaction chamber outlet 12 .

[0042] Among them, the heat pipe is a kind of heat transfer device with excellent thermal co...

Embodiment 2

[0061] refer to Figure 4 and Figure 5 , the present embodiment provides another liquid fuel catalytic reforming device, the liquid fuel catalytic reforming device includes a housing and a high-temperature heat pipe 2; the housing includes an inner housing 101 and an outer housing 102, and the interior of the inner housing 101 is arranged There is a first reaction chamber, and a second reaction chamber is arranged inside the outer casing 102. The inside of the first reaction chamber includes a catalytic reforming area, and the catalytic reforming area is used to fill the catalyst 3; A first reaction chamber inlet 1011 and a first reaction chamber outlet 1012 are respectively provided at both ends of the entire region, and the high-temperature heat pipe 2 is configured to be able to be assembled inside the catalytic reforming region to balance the catalyst filled inside the catalytic reforming region 3 the temperature along the direction extending from the first reaction cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com