Method of fabricating gate oxide layer on silicon carbide material

A gate oxide layer and oxide layer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of the number of trap charges in the interface state and the reduction of oxide layer charges, so as to reduce the number of charges and gate oxidation. Layer densification, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

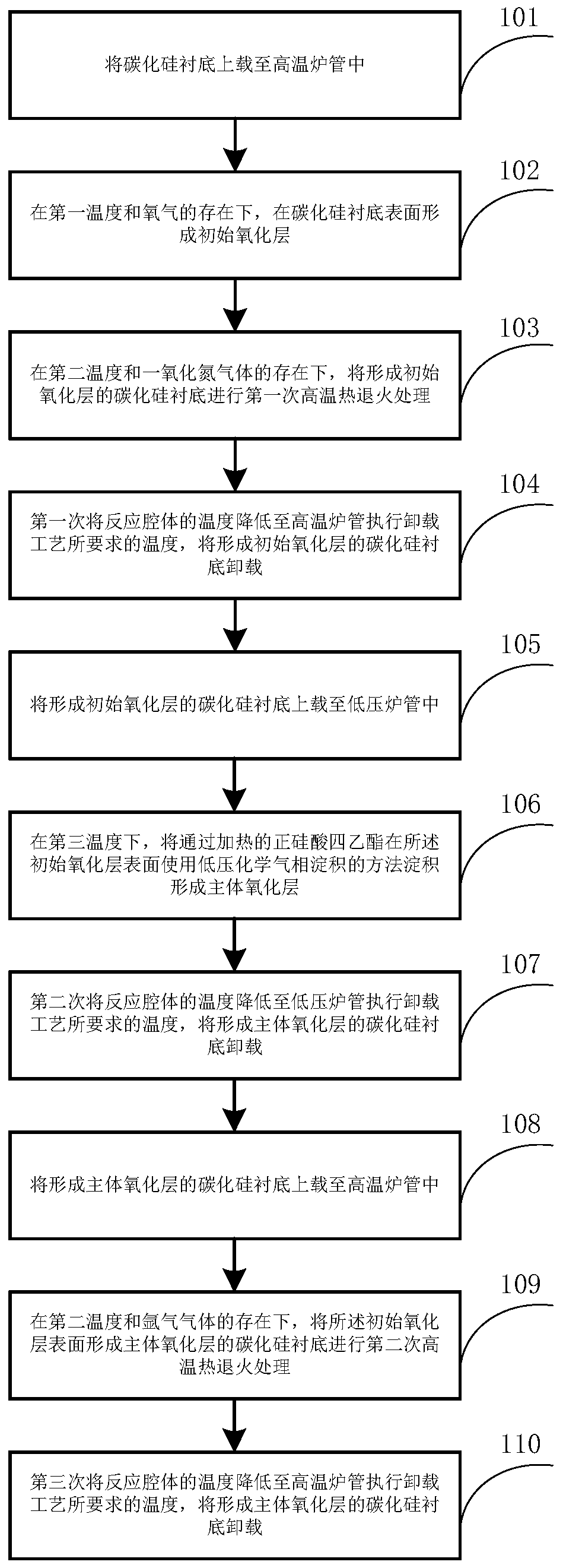

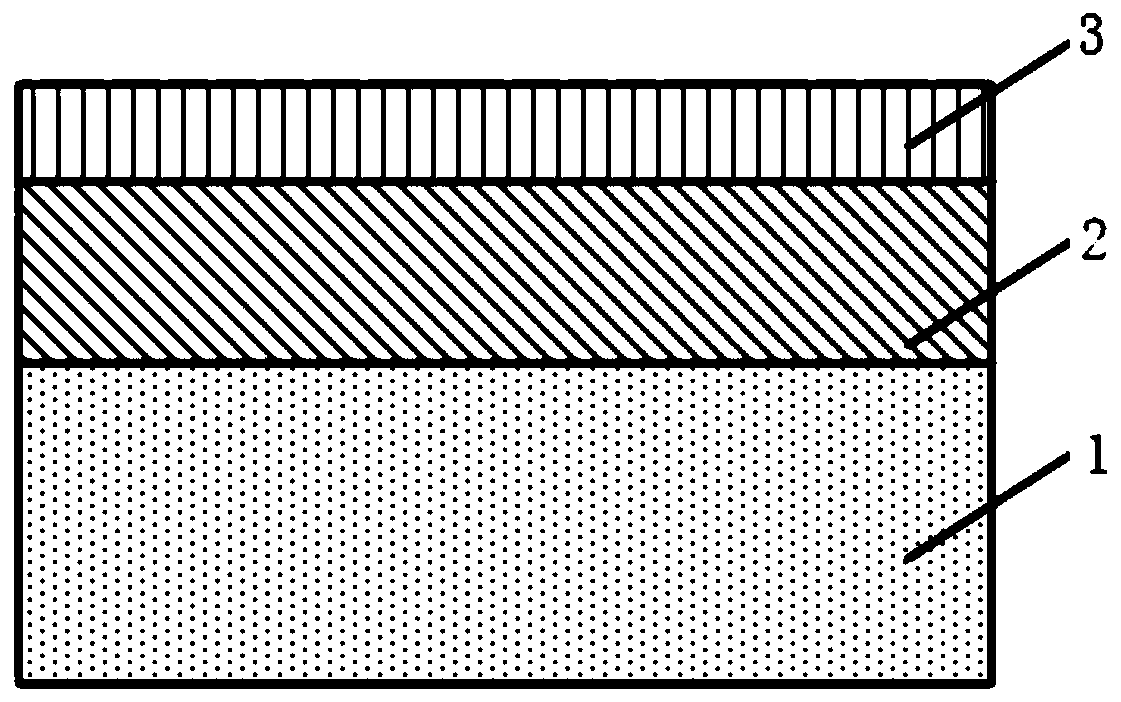

[0050] figure 1 It is a schematic flow chart of the method for manufacturing a gate oxide layer on a silicon carbide material provided in Embodiment 1 of the present invention, image 3 A schematic diagram of the structure obtained by the method for manufacturing the gate oxide layer according to the embodiment of the present invention, as shown in figure 1 and image 3 As shown, the method for manufacturing the gate oxide layer on the silicon carbide material proposed by the present invention comprises the following steps:

[0051] In step 101, a silicon carbide substrate 1 is provided and placed in a high-temperature furnace tube;

[0052] Then set the pressure of the high-temperature furnace tube to 900mbar, and raise the temperature inside the furnace tube to 1150°C at a heating rate of 10°C / min;

[0053] In step 102, oxygen is introduced into the furnace tube, the oxygen flow rate is 1 slm / min, and an initial oxide layer 2 with a thickness of 13 nm is formed on the sur...

Embodiment 2

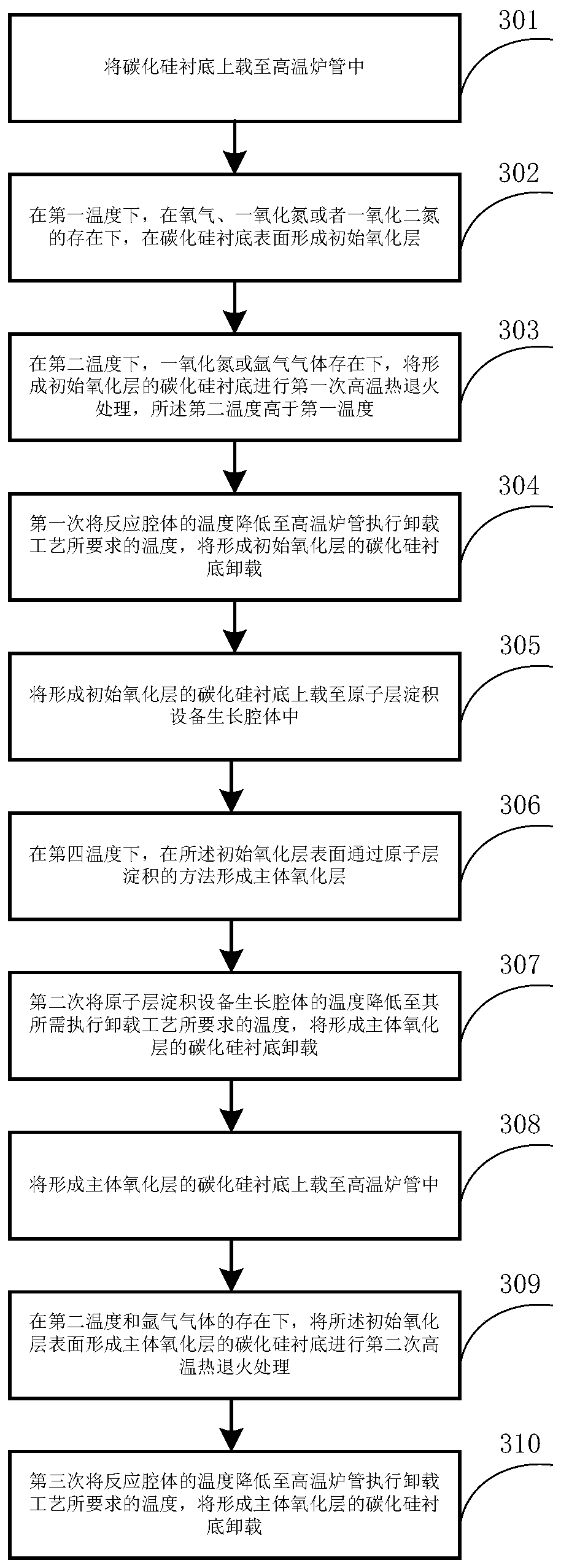

[0066] figure 2 It is a schematic flowchart of a method for manufacturing a gate oxide layer on a silicon carbide material provided in Embodiment 2 and Embodiment 3 of the present invention, image 3 A schematic diagram of the structure obtained by the method for manufacturing the gate oxide layer according to the embodiment of the present invention, as shown in figure 2 and image 3 As shown, the method for manufacturing the gate oxide layer on the silicon carbide material proposed by the present invention comprises the following steps:

[0067] In step 301, a silicon carbide substrate 1 is provided and placed in a high-temperature furnace tube;

[0068] Then set the pressure of the furnace tube to 950mbar, and raise the temperature inside the furnace tube to 1200°C at a heating rate of 10°C / min;

[0069] In step 302, nitrogen monoxide is fed into the furnace tube, the flow rate of nitrogen monoxide is 1 slm / min, and an initial oxide layer 2 with a thickness of 12 nm is ...

Embodiment 3

[0082] figure 2 It is a schematic flowchart of a method for manufacturing a gate oxide layer on a silicon carbide material provided in Embodiment 2 and Embodiment 3 of the present invention, image 3 A schematic diagram of the structure obtained by the method for manufacturing the gate oxide layer according to the embodiment of the present invention, as shown in figure 2 and image 3 As shown, the method for manufacturing the gate oxide layer on the silicon carbide material proposed by the present invention comprises the following steps:

[0083] In step 301, a silicon carbide substrate 1 is provided and placed in a high-temperature furnace tube;

[0084] Then set the pressure of the furnace tube to 1000mbar, and raise the temperature inside the furnace tube to 1000°C at a heating rate of 8°C / min;

[0085] In step 302, nitrous oxide is fed into the furnace tube, the flow rate of nitrous oxide is 0.8 slm / min, and an initial oxide layer 2 with a thickness of 15 nm is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com