Construction method of assembly type steel pipe piece formwork suitable for rapid lining of circular tunnel

A construction method and prefabricated technology, applied in the direction of tunnel lining, shaft lining, tunnel, etc., can solve the problems of affecting traffic, low formwork utilization efficiency, affecting tunnel lining speed, etc., to improve construction efficiency and optimize the efficiency of quick disassembly and assembly , Improving the effect of lining utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for constructing fabricated steel sheet formwork suitable for rapid lining of circular tunnels, which mainly includes the following steps:

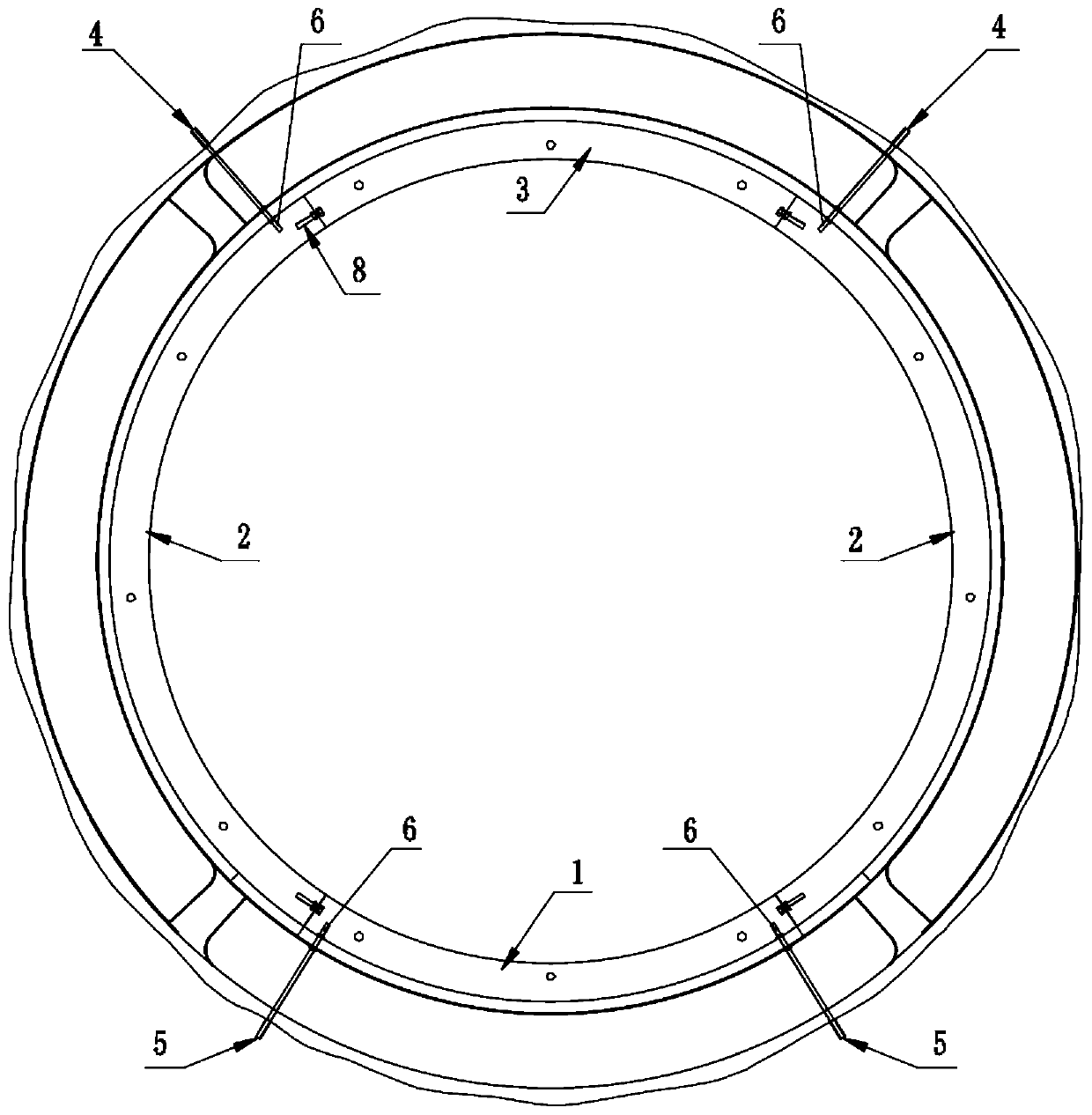

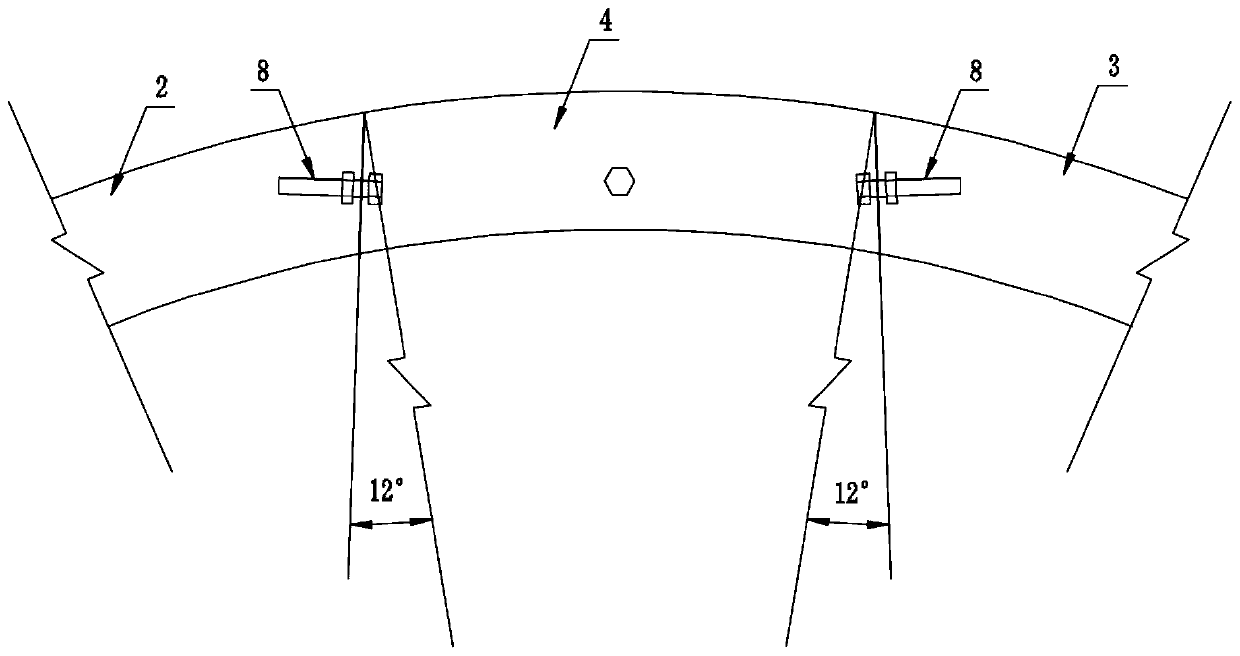

[0039] S1: if figure 1 As shown, combined with the specific characteristics of the circular lining, considering the requirements of quick installation and convenient transportation, the assembled steel pipe sheet formwork for the circular tunnel lining is designed as a formwork unit with a length of 4 meters along the axial direction of the tunnel, and each tunnel formwork unit Divided into bottom formwork 1, left and right side standard formwork 2 and top formwork 3;

[0040] S2: if figure 1 As shown, when the circular tunnel is excavated, the casing 4 is pre-embedded in the left and right sides of the surrounding rock corresponding to the assembled steel pipe sheet template;

[0041] S3: if Figure 8 , 9 As shown, in the steel pipe sheet formwork processing plant, prefabrication is carried out according to the bottom...

Embodiment 2

[0048] A method for constructing fabricated steel sheet formwork suitable for rapid lining of circular tunnels, which mainly includes the following steps:

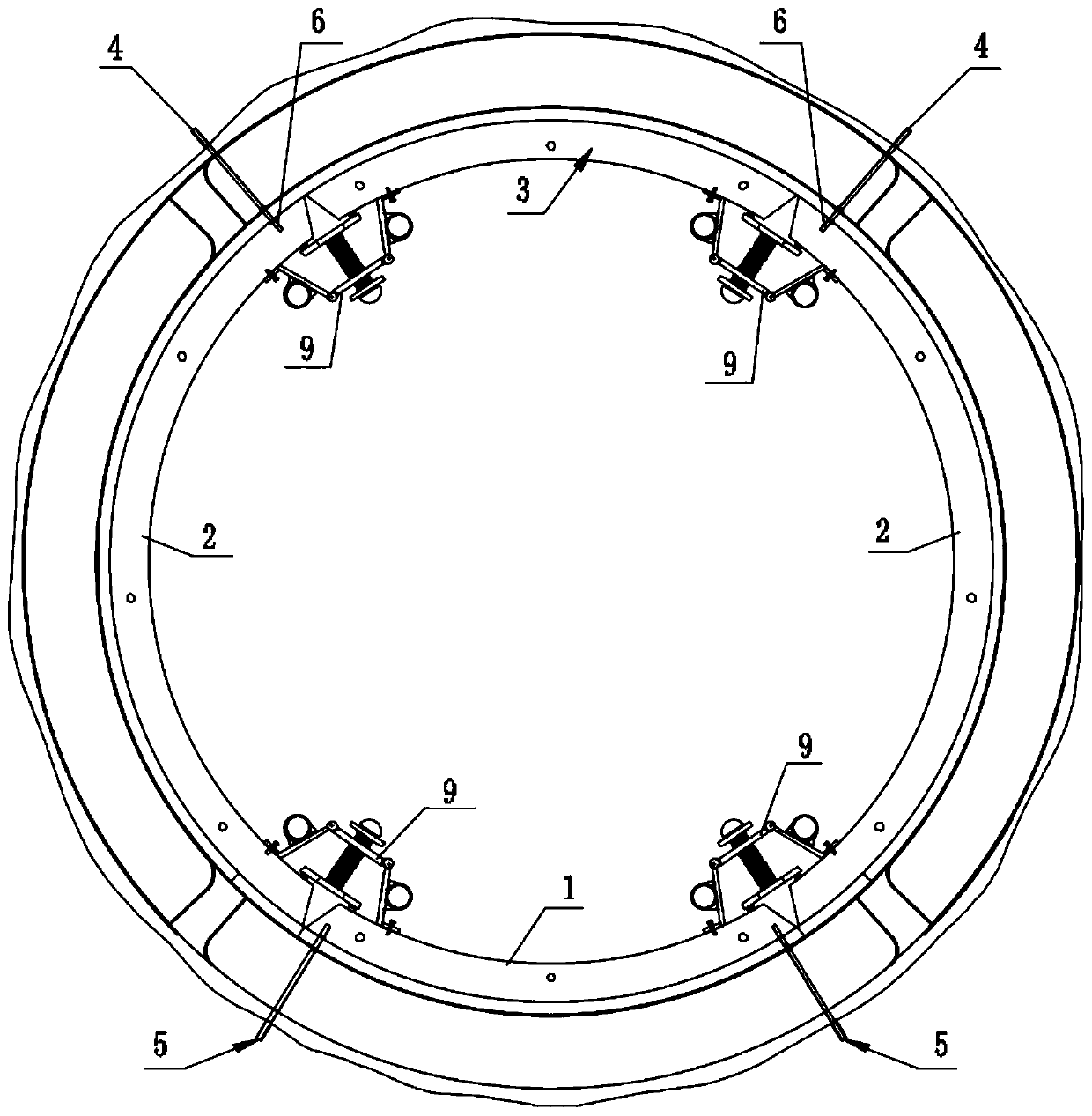

[0049] S1: if image 3 As shown, combined with the specific characteristics of the circular lining, considering the requirements of quick installation and convenient transportation, the assembled steel pipe sheet formwork for the circular tunnel lining is designed as a formwork unit with a length of 4 meters along the axial direction of the tunnel, and each tunnel formwork unit Divided into bottom formwork 1, left and right side standard formwork 2 and top formwork 3;

[0050] S2: if image 3 As shown, when the circular tunnel is excavated, the casing 4 is pre-embedded in the left and right sides of the surrounding rock corresponding to the assembled steel pipe sheet template;

[0051] S3: if Figure 7 , 8 As shown, in the steel pipe sheet formwork processing plant, prefabrication is carried out according to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com