Piezoresistive sensor material and preparation method and application thereof

A sensor device and piezoresistive technology, applied in the field of piezoresistive sensor device materials and their preparation, can solve problems such as poor force sensitivity and low electrical conductivity, and achieve improved mechanical strength, pore wall integrity, and good cyclic compression performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

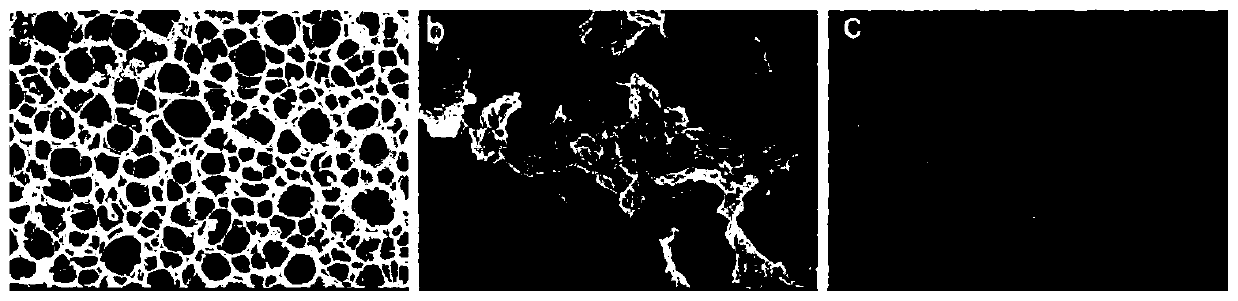

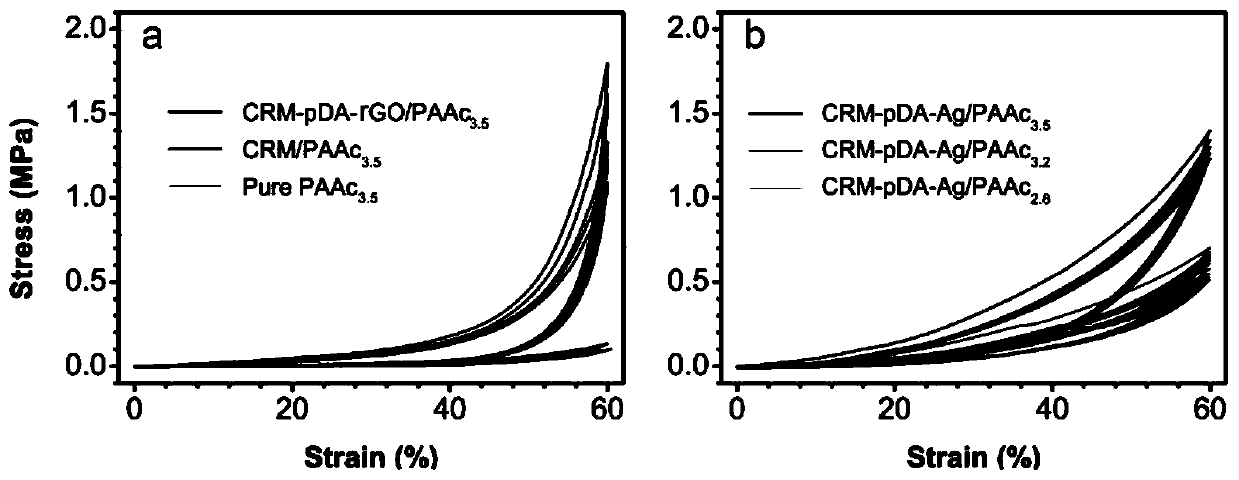

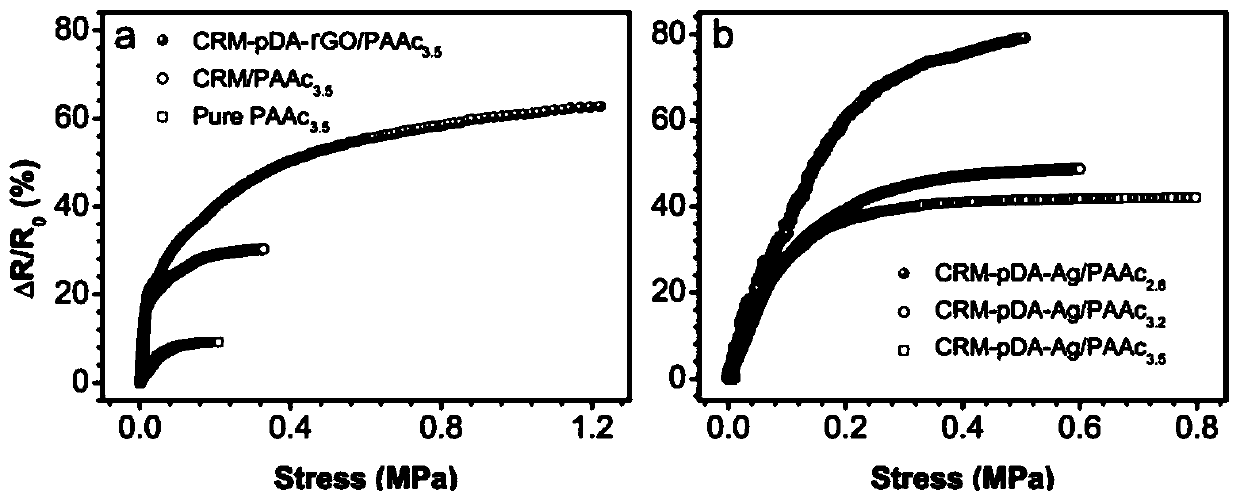

Image

Examples

Embodiment 1

[0046] A preparation method of piezoresistive sensor material, comprising the following steps:

[0047] S1: Use ionic liquid to treat poplar wood powder with a particle size of 60 mesh, then solify it, chemically cross-link-gelize it, and freeze-dry to obtain lignocellulosic aerogel. The specific operations include: S11: Add 1-ethyl -Add 4% wood powder in mass fraction to 3-methyl-imidazole acetate ionic liquid, then heat and stir at 110°C for 24h to form a suspension, then transfer the suspension to 8 times its volume , the concentration is 40% v / v acetone aqueous solution, stir 1h, suction filter and wash to obtain filter residue, filter residue is dried at 100 ℃ to obtain wood fiber; S12: add the wood fiber to 4wt% NaOH and 4wt% urea In the aqueous solution, the mass ratio of the wood fiber to the aqueous solution is 0.8:100. After the suspension is formed, it is frozen at -40°C for 9 hours, then thawed at room temperature, and the above freeze-thaw treatment is repeated 3 ...

Embodiment 2

[0053] A preparation method of piezoresistive sensor material, comprising the following steps:

[0054] S1: Use ionic liquid to treat balsa wood powder with a particle size of 100 meshes, then solify it, chemically cross-link-gelize it, and freeze-dry to obtain lignocellulosic airgel. The specific operations include: S11: Add 1-ethyl - Add 6% wood flour by mass fraction to 3-methyl-imidazole acetate ionic liquid, then heat and stir at 185°C for 30min to form a suspension, then transfer the suspension to 10 times its volume , the concentration is 60% v / v acetone aqueous solution, stir 3h, suction filter and wash to obtain filter residue, filter residue is dried at 110 ℃ to obtain wood fiber; S12: add described wood fiber to 4wt% NaOH and 4wt% urea In the aqueous solution, the mass ratio of the wood fiber to the aqueous solution is 1.5:100 to form a suspension, which is then frozen at -20°C for 9 hours and then thawed at room temperature, and the above-mentioned freeze-thaw trea...

Embodiment 3

[0060] A preparation method of piezoresistive sensor material, comprising the following steps:

[0061] S1: Use ionic liquid to treat poplar wood powder with a particle size of 80 mesh, then solify it, chemically cross-link-gelize it, and freeze-dry to obtain lignocellulosic airgel. The specific operations include: S11: Add 1-ethyl -Add 5% wood powder by mass fraction to 3-methyl-imidazole acetate ionic liquid, then heat and stir at 147.5°C for 9h to form a suspension, then transfer the above suspension to 9 times its volume , the concentration is 50% v / v acetone aqueous solution, stir 2h, suction filter and wash to obtain filter residue, filter residue is dried at 105 ℃ to obtain wood fiber; In the aqueous solution, the mass ratio of the wood fiber to the aqueous solution is 1.0:100 to form a suspension, which is then frozen at -30°C for 9 hours and then thawed at room temperature, and the above-mentioned freeze-thaw treatment is repeated 4 times to obtain solified wood fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com