A preparation method of nano needle tip with controllable crystal orientation and size

A crystal orientation and needle tip technology, applied in nanotechnology and other directions, can solve the problems of uncontrollable nano single particle grain structure and size, and difficult calculation of the contact state between particles and needle tip, so as to facilitate analysis and processing operations, and achieve controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

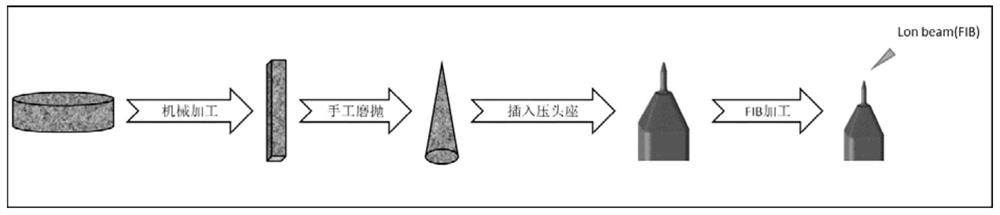

[0036] CeO prepared in this example with controllable crystal orientation and size 2 Nano needle tip size r=120nm, the preparation method comprises the following steps:

[0037] 1) Cut the cerium oxide block material prepared in the previous stage into a cuboid of 5mm×1mm×1mm by machining. Then use manual grinding and polishing to process the shape into a needle point shape. In order to match the TI950 indenter seat, the size of the thickest end of the needle point should not exceed 0.2 mm, and the tip size should be processed to 50 μm.

[0038] 2) Manually place the CeO under a standing microscope 2 The micron needle tip is inserted into the indenter seat, fixed with metal thermosetting glue, and the micron needle tip and the indenter seat are put into the FIB vacuum chamber together.

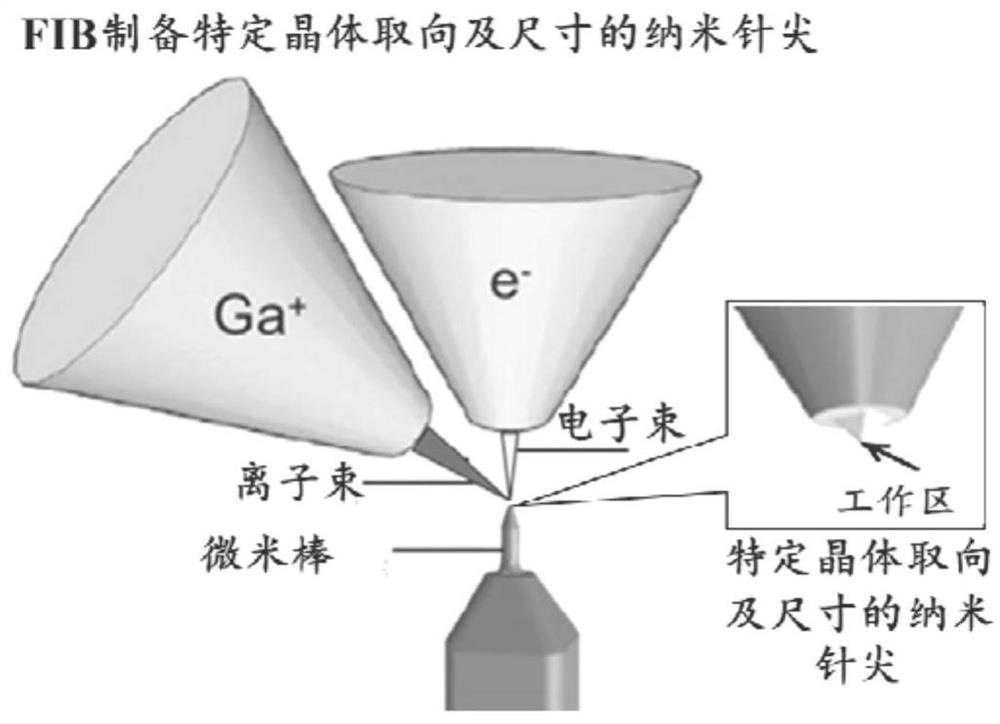

[0039] 3) Use the EBSD probe in the FIB system to analyze and test the crystal orientation of the micron tip, and select suitable grains for processing.

Embodiment 2

[0043]CeO prepared in this example with controllable crystal orientation and size 2 Nano tip size r=180nm, the preparation method comprises the following steps:

[0044] 1) Firstly, the cerium oxide bulk material prepared in the previous stage is cut into a 5mm×1mm×1mm cuboid by machining. Then use manual grinding and polishing to process the shape into a needle point shape. In order to match the TI950 indenter seat, the size of the thickest end of the needle point should not exceed 0.2 mm, and the tip size should be processed to 50 μm.

[0045] 2) Manually place the CeO under a standing microscope 2 The micron needle tip is inserted into the indenter seat, fixed with metal thermosetting glue, and the micron needle tip and the indenter seat are put into the FIB vacuum chamber together.

[0046] 3) Use the EBSD probe in the FIB system to analyze and test the crystal orientation of the micron tip, and select suitable grains for processing.

Embodiment 3

[0050] CeO prepared in this example with controllable crystal orientation and size 2 Nano needle tip size r=270nm, the preparation method comprises the following steps:

[0051] 1) Firstly, the cerium oxide bulk material prepared in the previous stage is cut into a 5mm×1mm×1mm cuboid by machining. Then use manual grinding and polishing to process the shape into a needle point shape. In order to match the TI950 indenter seat, the size of the thickest end of the needle point should not exceed 0.2 mm, and the tip size should be processed to 50 μm.

[0052] 2) Manually place the CeO under a standing microscope 2 The micron needle tip is inserted into the indenter seat, fixed with metal thermosetting glue, and the micron needle tip and the indenter seat are placed together in the FIB vacuum chamber and processed by gallium ion beam (vacuum degree is ~10 -6 mbar).

[0053] 3) Use the EBSD probe in the FIB system to analyze and test the crystal orientation of the micron tip, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com