Immersion type side water injection nozzle capable of improving crystallizer flow field for continuous casting

A crystallizer and water nozzle technology, which is applied in casting equipment, casting melt containers, metal processing equipment, etc., to achieve the effects of optimizing heat distribution, improving heat transfer, and promoting high casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

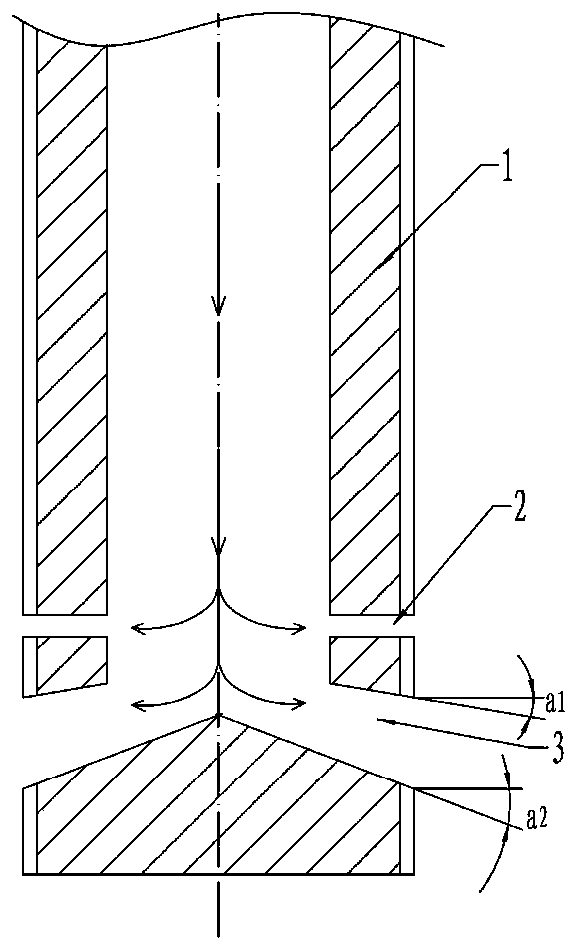

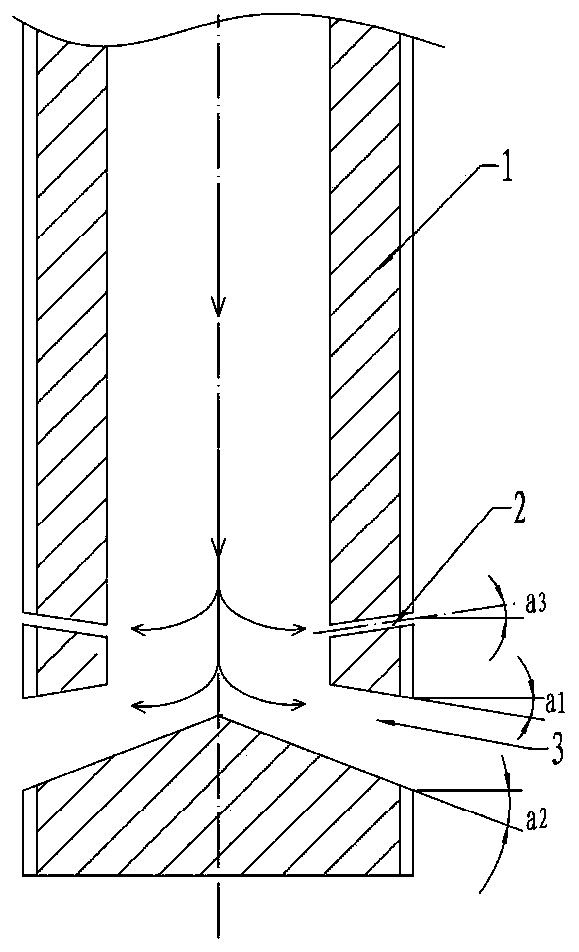

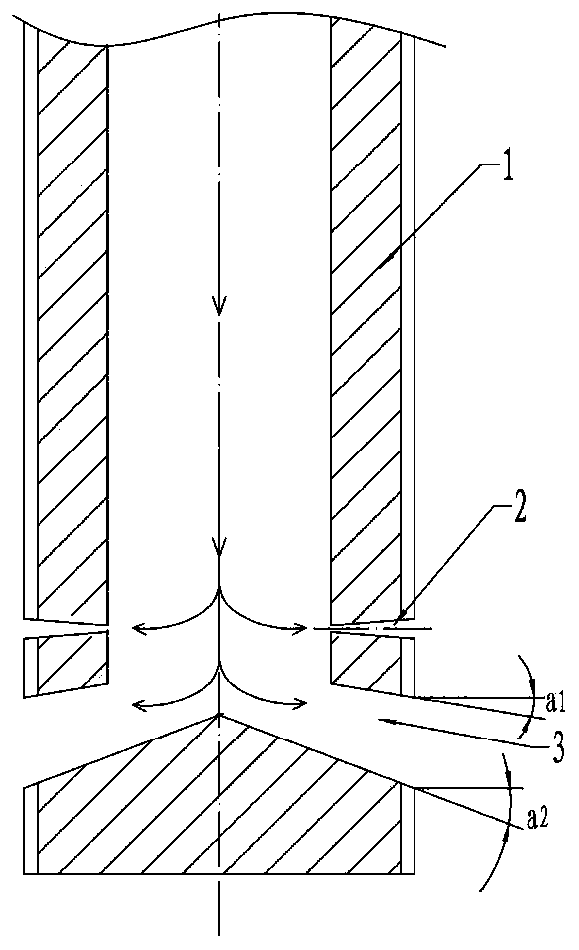

[0018] see figure 1 , The continuous casting submerged side spout for improving the flow field of the mold according to the present invention is arranged in the mold, including symmetrically arranged main side holes 3, and the cross-sectional shape of the main side holes is square or rectangular. An important improvement of the present invention is that the upper surface of the main side hole has an upward inclination a1, and the lower surface has a downward inclination a2, the upward inclination is smaller than the downward inclination, and the difference between the upward inclination and the downward inclination is 3°-5°. Wherein, the degree of the upward inclination angle is not less than 10°, and the degree of the downward inclination angle is not greater than 20°. The main side holes are set with different upward and downward angles, and the upward angle is smaller than the downward angle, so that when the molten steel flows out from the two main side holes, the upward a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com